Process of dyeing silk with dye yam extract

A dyeing method and technology of extracting liquid are applied in the dyeing field of natural silk dyes, which can solve the problems of single color, withering, complicated production process, etc., and achieve the effects of simple dyeing method, controllable dyeing process, and shortening of process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Preparation of Dioscorea spp.: Peel the skin and smash the tuber of Diossigma, weigh a certain quality of dioscorea powder according to the solvent-solute ratio of 20:1, and extract it with a 60% acetone aqueous solution in a constant temperature water bath at 60°C for 2h, and then stand still After the precipitation was filtered, the acetone was distilled off under reduced pressure to prepare the dioscorea spp.

[0017] (2) Real silk dipping treatment: Dilute the yam extract extract into a dipping solution, and heat to 60℃ at a bath ratio of 1:50. The concentration of the yam extract can be based on the concentration of the original solution and the final dyeing depth required for the product Adjust, immerse the 11206 silk power spinning in the above-mentioned immersion liquid, and treat it at a constant temperature for 75 minutes.

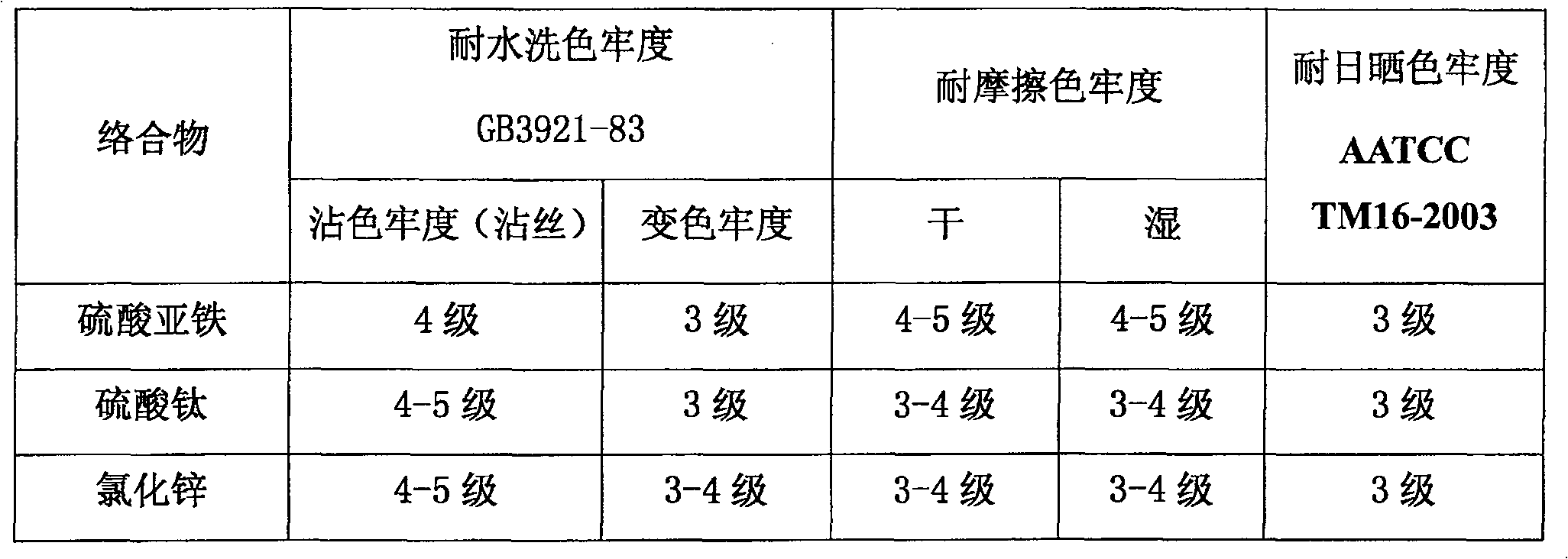

[0018] (3) Complexing treatment: Treat the impregnated silk in an aqueous solution of 15% ferrous sulfate (w / w to the fabric mass) at 30°...

Embodiment 2

[0020] Follow the steps of Example 1 (1) to prepare the dioscorea extract, (2) the real silk dipping treatment, and then put the treated real silk in a bath of 30℃, 12% titanium sulfate (ratio W / W to the fabric mass) (Adjust the pH to 3 with a buffer solution) for 15 minutes, then heat up to 85°C at 3°C / min, shake at a constant temperature for 30 minutes, take out, saponify, wash in water, and dry. The obtained silk is orange-yellow (reddish light), the color fastness properties of the obtained product are shown in Table 1, and the UV resistance and other comprehensive properties are shown in Table 2.

Embodiment 3

[0022] (1) Preparation of dioscorea extract: the same as in Example 1.

[0023] (2) Real silk impregnation treatment: same as Example 1.

[0024] (3) Complexing treatment: The silk that has been treated with the extract is continuously treated at 30°C in a 6% zinc chloride (ratio to fabric mass W / W) bath (adjusted to pH 7 with a buffer solution) for 15 minutes, Then, the temperature was raised to 75°C at 3°C / min, and after shaking at a constant temperature for 30 minutes, it was taken out for soaping, washed with water, and dried. The obtained silk is light yellow (reddish light), the color fastness properties of the obtained product are shown in Table 1, and the UV resistance and other comprehensive properties are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com