A kind of polyester dyeing method utilizing nano lanthanum oxide

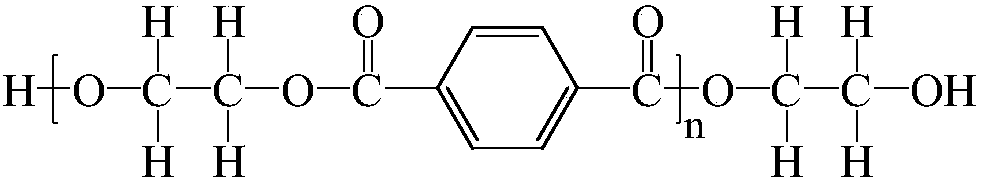

A technology of nano-lanthanum oxide and dyeing method, which is applied in the field of polyester dyeing using nano-lanthanum oxide, which can solve the problems of poor hydrophilicity and unfavorable dyeing of polyester, and achieve the effects of lower glass transition temperature, low cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Step 1, surface modification of nano lanthanum oxide spheres

[0054] Add 94.1g of absolute ethanol and 5g of stearic acid into the flask, weigh 0.9g of nano-lanthanum oxide, add it into the flask, ultrasonically oscillate at room temperature and stir for 25min at the same time; take out the flask, place it in an oil bath at 75°C, and reflux at a constant temperature for 5.5 After h, use a Buchner funnel to carry out suction filtration, then wash with absolute ethanol, and finally put it into a vacuum drying oven and dry it at 75°C for 23 hours to obtain surface-modified lanthanum oxide;

[0055] Step 2, alkali treatment of polyester

[0056] Weigh 2g of polyester, put it in a sodium hydroxide solution with a concentration of 45g / L, the bath ratio is 1:45, and react at a constant temperature of 93°C for 3.5h. After the reaction is completed, wash it with distilled water until it is neutral, and dry it at 75°C;

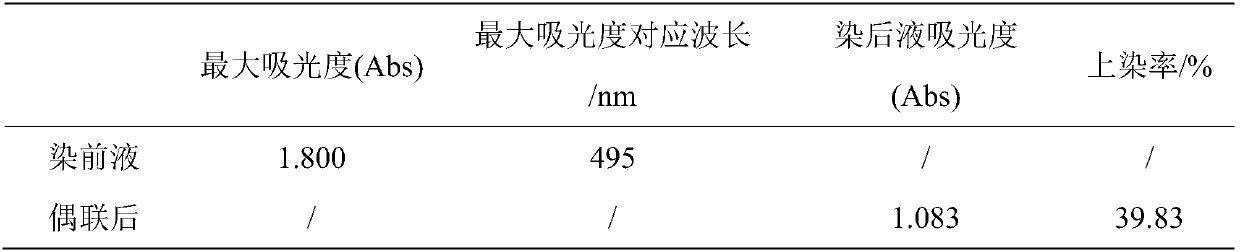

[0057] Step 3, coupling the surface-modified lanthanum ox...

Embodiment 2

[0065] Step 1, surface modification of nano lanthanum oxide spheres

[0066] Add 91.9g of absolute ethanol and 7g of stearic acid into the flask, weigh 1.1g of nano-lanthanum oxide, add it into the flask, ultrasonically oscillate at room temperature and stir for 35min at the same time; take out the flask, place it in an oil bath at 85°C, and reflux at a constant temperature for 6.5 After h, use a Buchner funnel to carry out suction filtration, then wash with absolute ethanol, and finally put it into a vacuum drying oven and dry it at 85°C for 25 hours to obtain surface-modified lanthanum oxide;

[0067] Step 2, alkali treatment of polyester

[0068] Weigh 2g of polyester, put it in a sodium hydroxide solution with a concentration of 55g / L, the bath ratio is 1:55, and react at a constant temperature at 97°C for 4.5h. After the reaction is completed, wash it with distilled water until neutral, and dry it at 85°C;

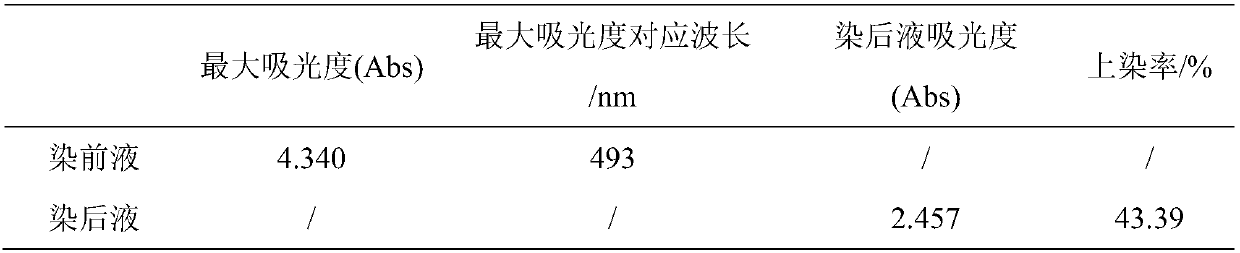

[0069] Step 3, coupling the surface-modified lanthanum oxide ob...

Embodiment 3

[0077] Step 1, surface modification of nano lanthanum oxide spheres

[0078] Add 93g of absolute ethanol and 6g of stearic acid into the flask, weigh 1g of nano-lanthanum oxide, add it into the flask, ultrasonically oscillate at room temperature and stir for 30min at the same time; take out the flask, place it in an oil bath at 80°C, and reflux at a constant temperature for 6h. Use a Buchner funnel to perform suction filtration, then wash with absolute ethanol, and finally put it into a vacuum drying oven at 80°C for 24 hours to obtain surface-modified lanthanum oxide;

[0079] Step 2, alkali treatment of polyester

[0080] Weigh 2g of polyester, put it in a sodium hydroxide solution with a concentration of 50g / L, the bath ratio is 1:50, and react at a constant temperature at 95°C for 4h. After the reaction is completed, wash it with distilled water until it is neutral, and dry it at 80°C;

[0081] Step 3, coupling the surface-modified lanthanum oxide obtained in step 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com