Ether alcohol type carrier dyeing method for polyimide fibers and fabric

A technology of polyimide fiber and polyimide, which is applied in the fields of textile printing and dyeing auxiliaries and textile dyeing and finishing, and can solve problems such as unsatisfactory effects and difficulty in dyeing dark colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

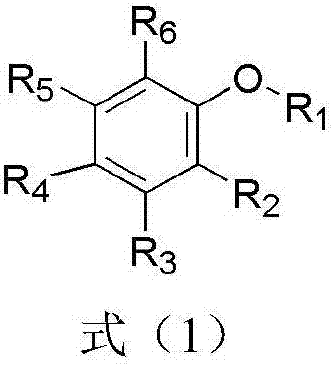

[0025] Choose a phenyl ether carrier, where R 1 for -CH 2 CH(OH)CH 3 , R 2 for -CH 3 ; 3 , R 4 , R 5 , and R 6 for -H.

[0026] Take 2g of polyimide knitted fabric, put it into a solution containing non-ionic surfactant AEO-7 (3g / L), the liquor ratio is 30:1, treat it at 85°C for 60min, wash it thoroughly and then dry it.

[0027] Put the polyimide fabric washed to remove impurities into a carrier containing 5% cationic blue X-GRRL and 50g / L of the weight of the fabric, wherein the bath ratio of the dye solution to the fabric is 20:1, at a speed of 2°C / min Raise the temperature to 125°C for 60 minutes. After the heat preservation was completed, the temperature was lowered to 80°C at a cooling rate of 2°C / min.

[0028] Put the fabric into the soap solution containing 3g / L non-ionic surfactant AEO-7, the liquor ratio is 30:1, treat the fabric at 95°C for 15min, then fully wash and dry.

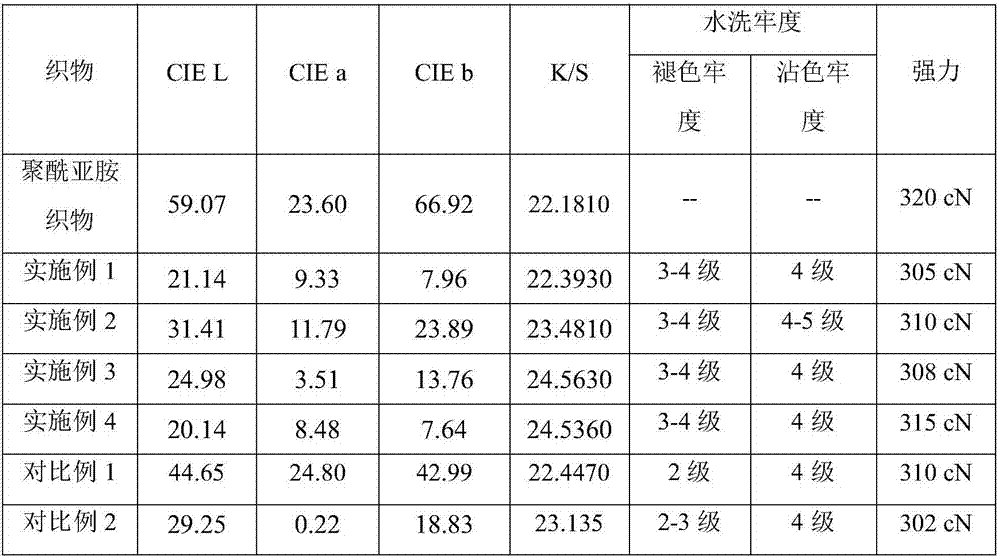

[0029] The color parameters and washing fastness of the dyed samples are shown in...

Embodiment 2

[0031] Select the phenyl ether carrier, R 1 for -CH 2 CH 2 OH,R 2 , R 3 , R 4 , R 5 , and R 6 for -H.

[0032] Take 2g of polyimide knitted fabric, put it into a solution containing nonionic surfactant AEO-7 (2g / L), the bath ratio is 30:1, treat it at 95°C for 30min, wash it with water and dry it.

[0033] Put the polyimide fabric that removes impurities into the carrier dye solution containing 2.5% cationic red X-GRL and 2.5% cationic blue X-GRRL and 10g / L to the weight of the fabric, wherein the bath ratio of dye solution to fabric The ratio is 15:1, and the temperature is raised to 120°C at a rate of 1.5°C / min and kept for 120min. After the heat preservation was completed, the temperature was lowered to 80°C at a cooling rate of 2°C / min.

[0034] Put the fabric into the soaping solution containing 2g / L nonionic surfactant AEO-7, the bath ratio is 20:1, treat the fabric at 85°C for 15min, then fully wash and dry.

[0035] The color parameters and washing fastness o...

Embodiment 3

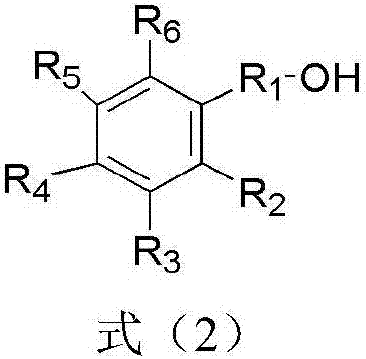

[0037] Select a phenyl alcohol carrier, where R 1 for -CH 2 -, R 2 , R 3 , R 4 , R 5 , and R 6 for -H.

[0038] Take 2g of polyimide knitted fabric, put it into a solution containing non-ionic surfactant AEO-7 (3g / L), the liquor ratio is 20:1, treat it at 95°C for 30min, wash it thoroughly and then dry it.

[0039] Put the polyimide fabric washed to remove impurities into the carrier dye solution containing 2.5% cationic blue X-GRRL and 50g / L of the weight of the fabric, wherein the bath ratio of the dye solution to the fabric is 30:1, at 3 ° C / min speed up to 130°C for 40min. After the heat preservation was completed, the temperature was lowered to 80°C at a cooling rate of 3°C / min.

[0040] Put the fabric into the soaping liquid containing 2g / L non-ionic surfactant AEO-7, the liquor ratio is 30:1, treat the fabric at 95°C for 30min, then fully wash and dry.

[0041] The color parameters and washing fastness of the dyed samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com