Rotary-piston engine and vehicle comprising an engine of this type

A piston engine, engine technology, applied in the direction of swing piston engine, swing piston engine, rotary or swing piston engine, etc., can solve the problems of low power density, deflagration, power loss, etc., and achieve dense and compact structure, wear and tear. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

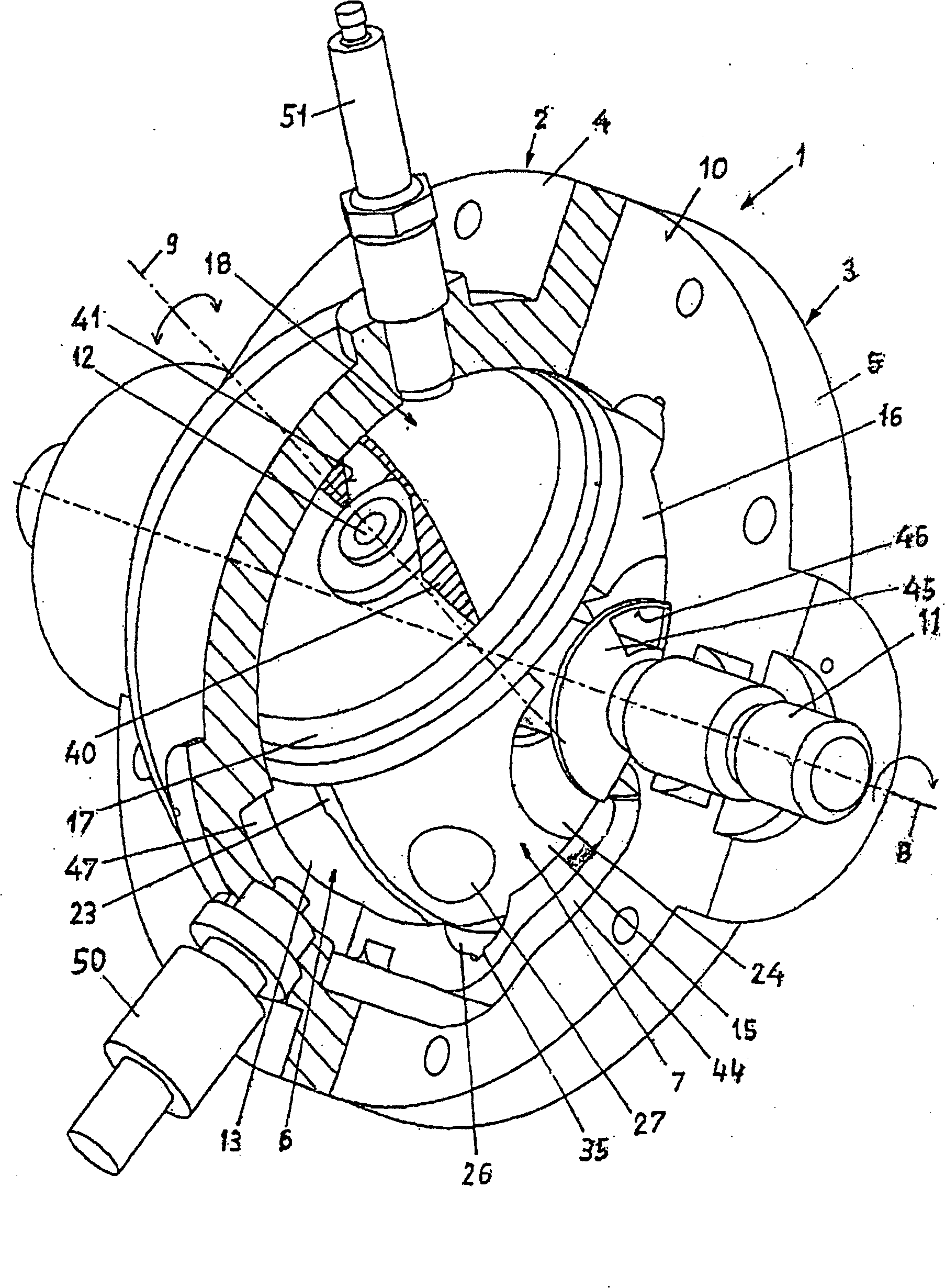

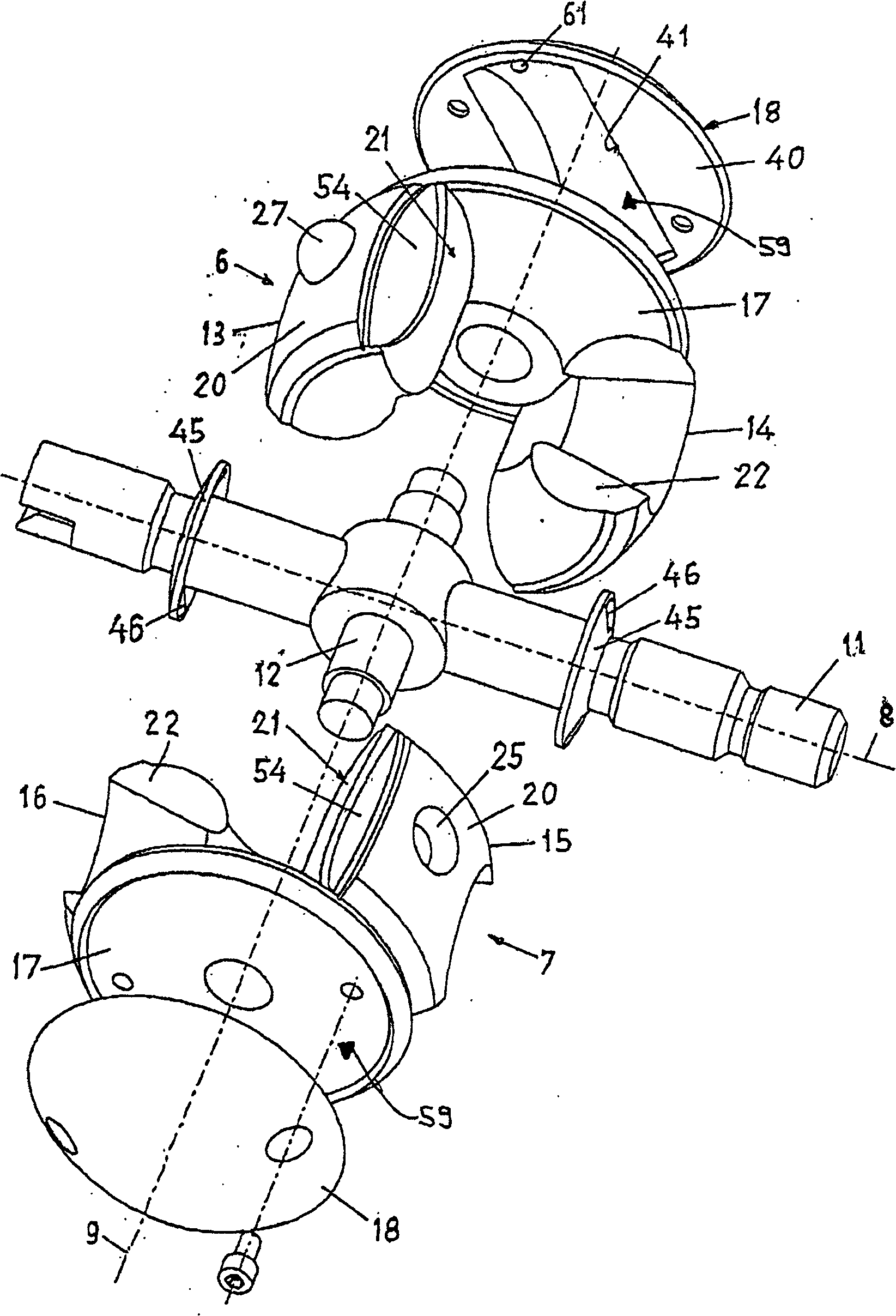

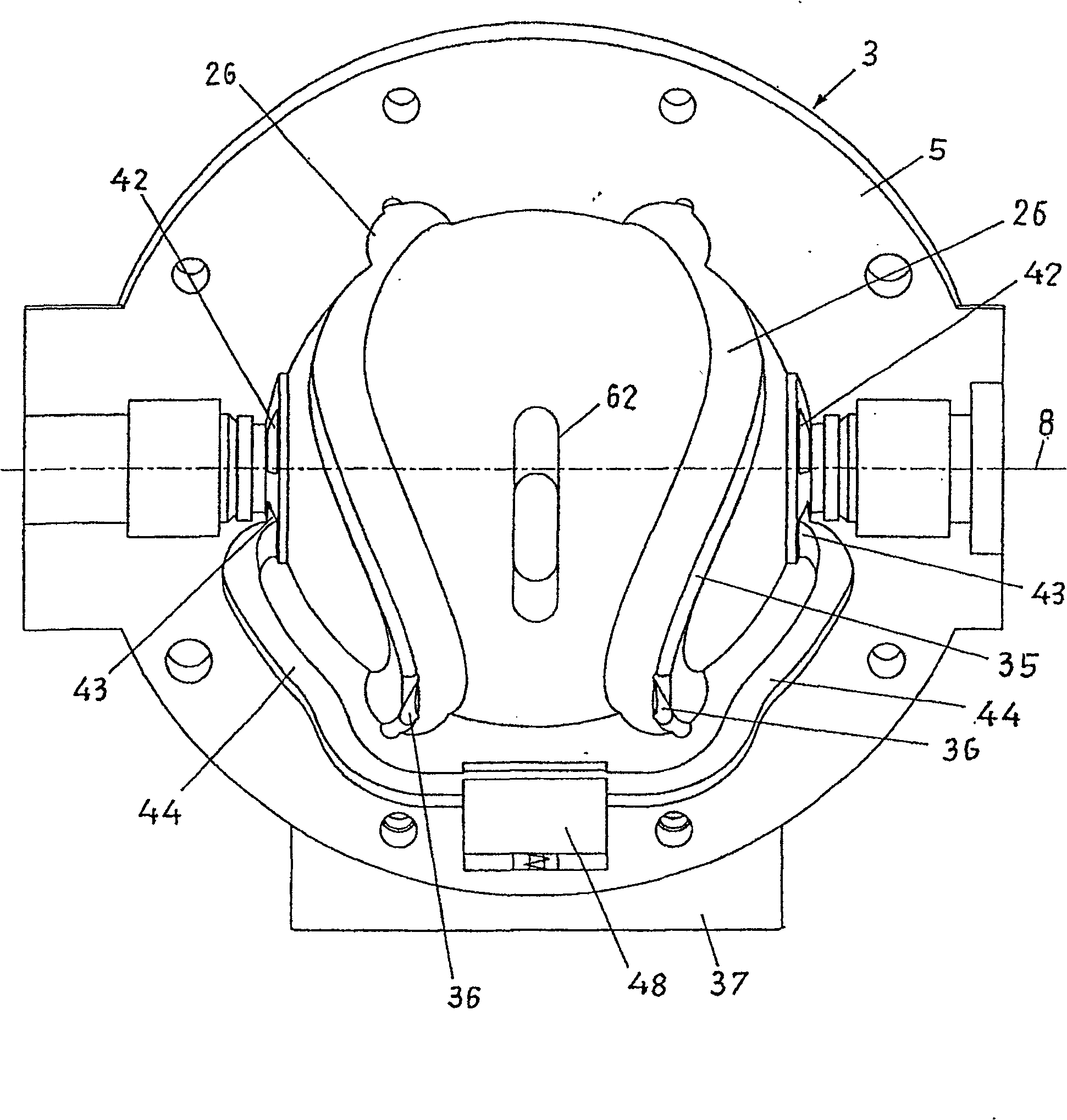

[0029] figure 1 The rotary piston engine shown is a forced-ignition engine, which has a generally spherical cylinder 1 with a spherical inner surface, which is divided by a dividing surface 10 into two half-cylinders 2 and 3, which are respectively connected by annular joints. Lan 4 and 5 and bolts not shown in the figure are connected to each other. Cylinder 1 is equipped with two double-armed rotary pistons 6 and 7, which rotate together around the rotation axis 8 at the center of the cylinder, and simultaneously generate a reciprocating rotary motion superimposed on the rotary motion, and the rotary motion revolves around the axis perpendicular to the rotation axis. 8 swing axis 9 to carry out. The rotary shaft 8 is formed by a shaft 11 , which is supported on both sides in the cylinder 1 and is designed as a driven shaft.

[0030] The rotary pistons 6 and 7 each have two piston arms 13, 14 or 15, 16 in the form of substantially diametrically opposite piston arms, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com