Friction clutch

A clutch and friction technology, applied in the field of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

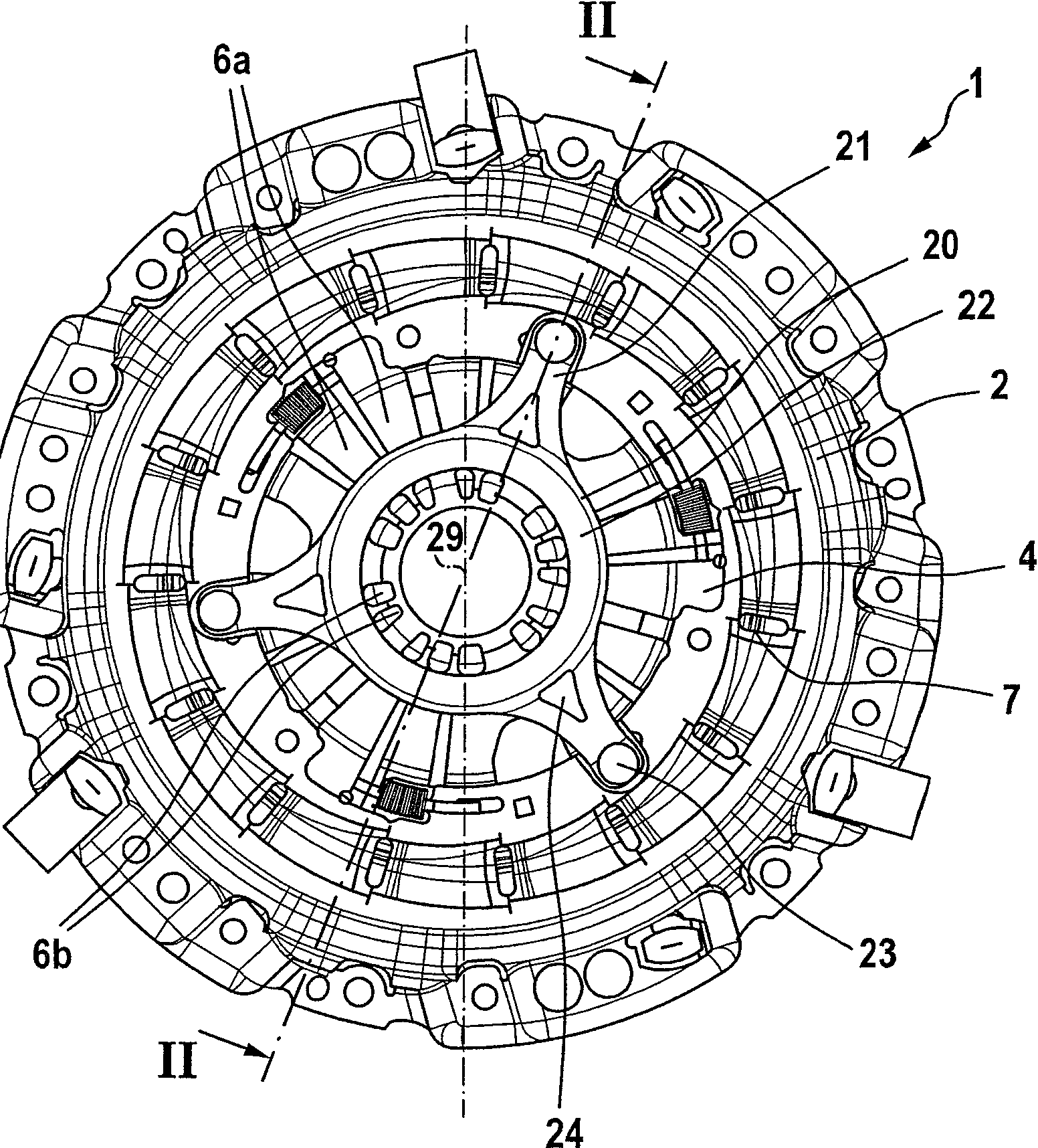

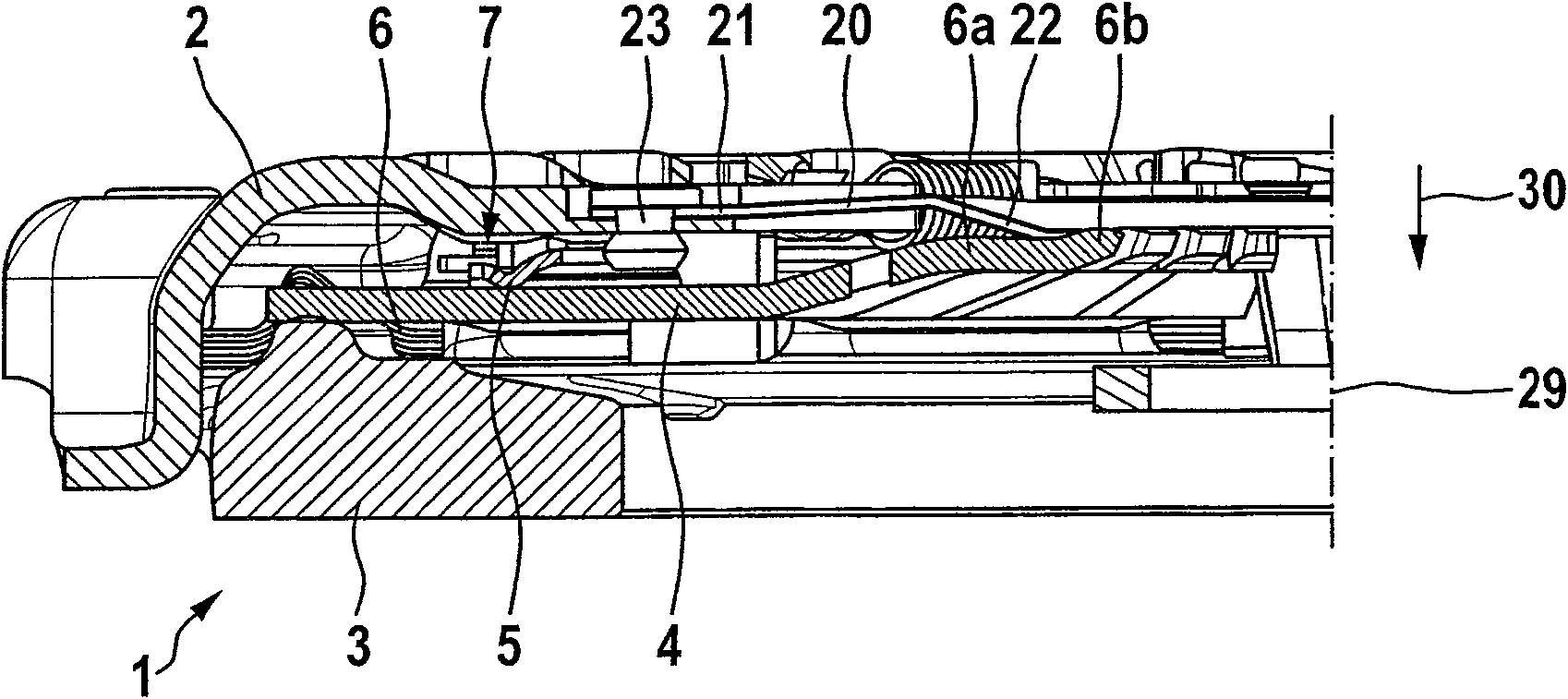

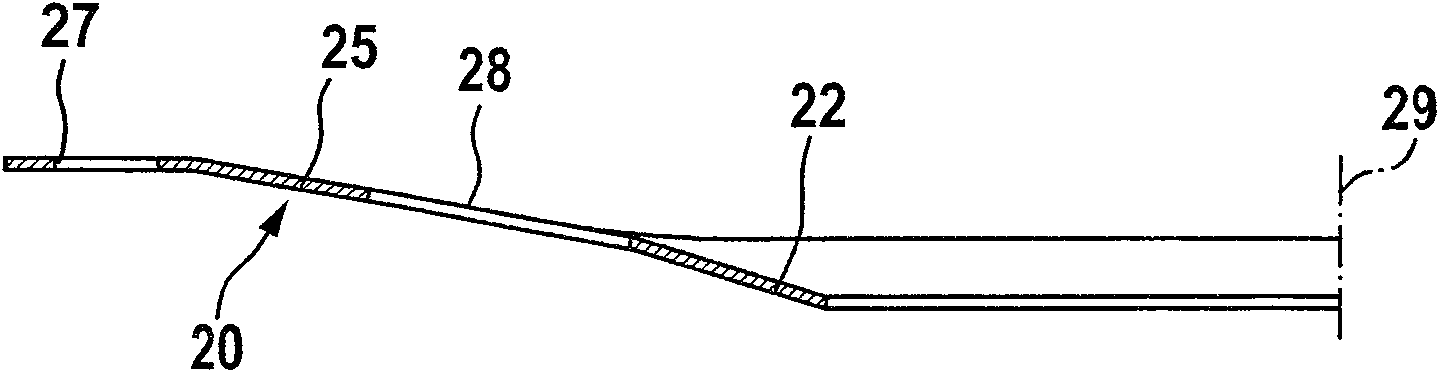

[0022] figure 1 and figure 2The friction clutch 1 shown in has the same characteristics as described in DE 10025850A1 in terms of the configuration of the compression disk spring 4 and its support on the clutch housing 2 and in the transmission connection between the pressure plate 3 and the cover 2 A structure similar to that described above. Furthermore, the friction clutch 1 has a self-acting or automatic compensating device 7 which is able to compensate for wear occurring at least on the friction linings of the clutch disc. In the embodiment shown here, the compensating device acts axially between the clutch housing 2 (cover) and the disk spring 4, so that the axial compensation adjustment of the disk spring 4 can compensate the wear and tear. In addition, reference can be made to the above-mentioned DE 10025850A1, DE 4322677A1, DE 19524827A1 and DE 19855583A1 regarding the function and configuration possibilities of this compensating device 7, the content of which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com