Bundle conductor set containing bundle conductor and retainer thereof, method for producing the bundle conductor

A technology of wire retention and wire harness, applied in the direction of electrical components, etc., can solve the problems of low efficiency, difficulty in reducing manufacturing costs, reducing work efficiency or labor productivity, etc., to achieve the goal of increasing the degree of freedom, improving work efficiency and dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

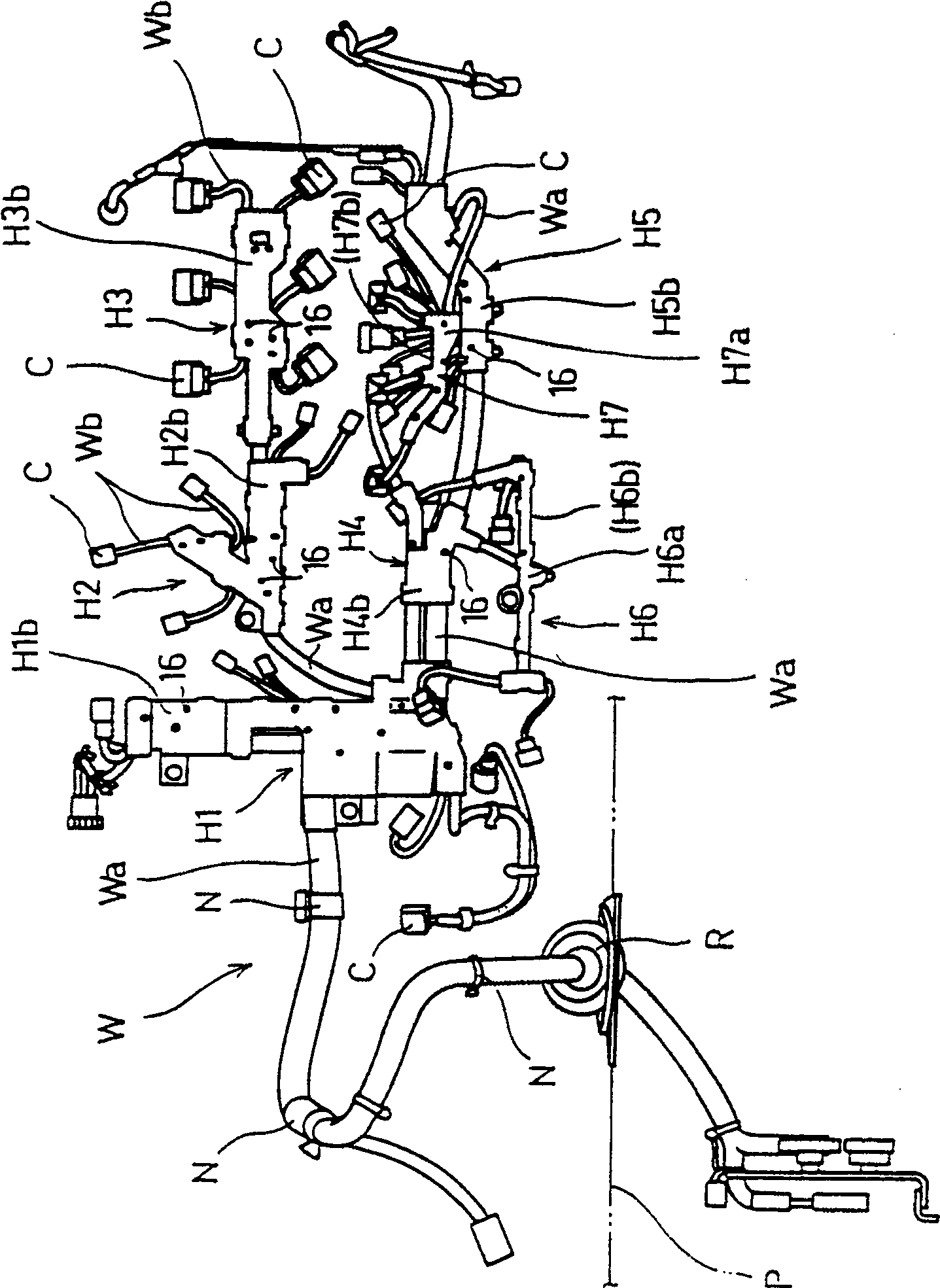

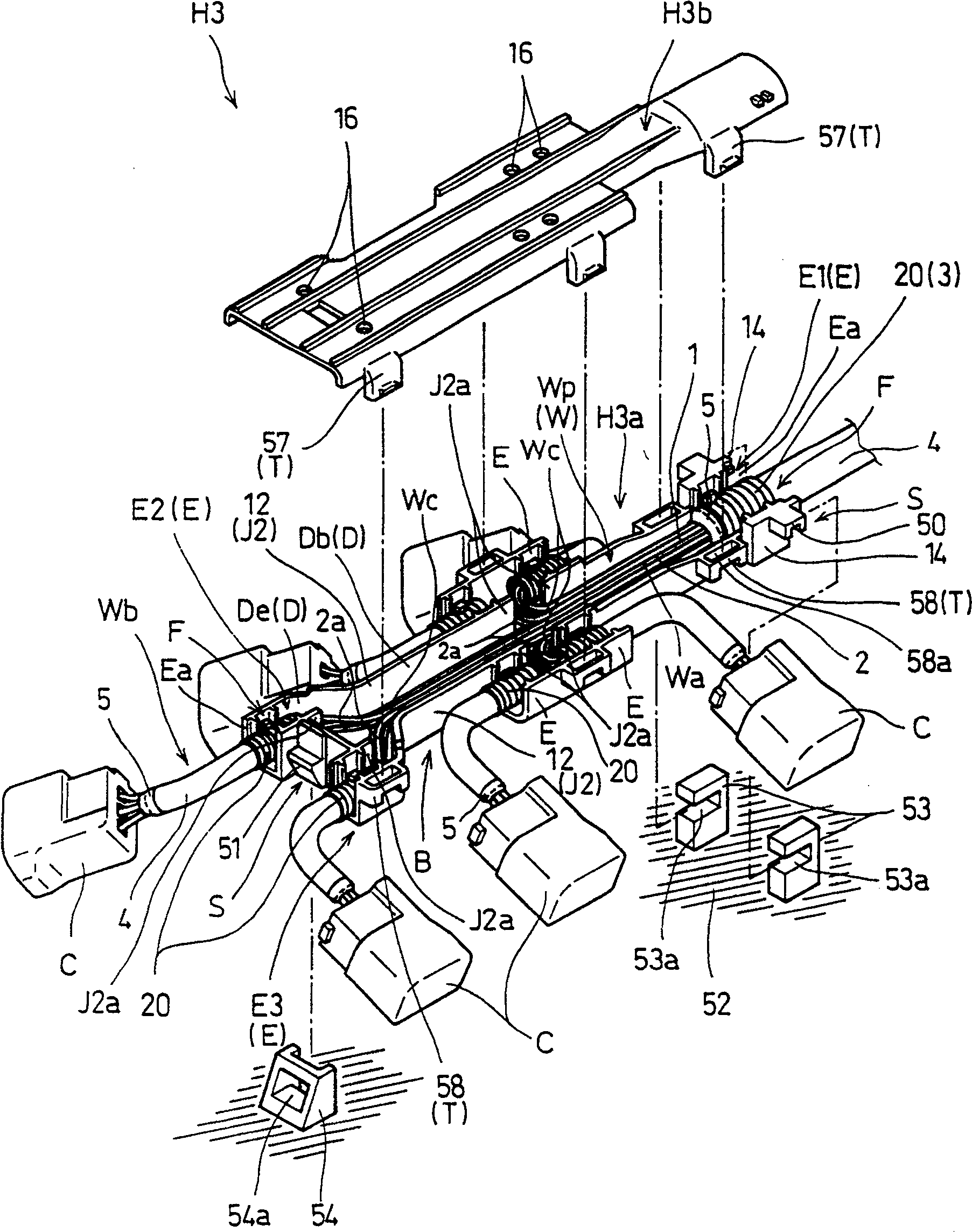

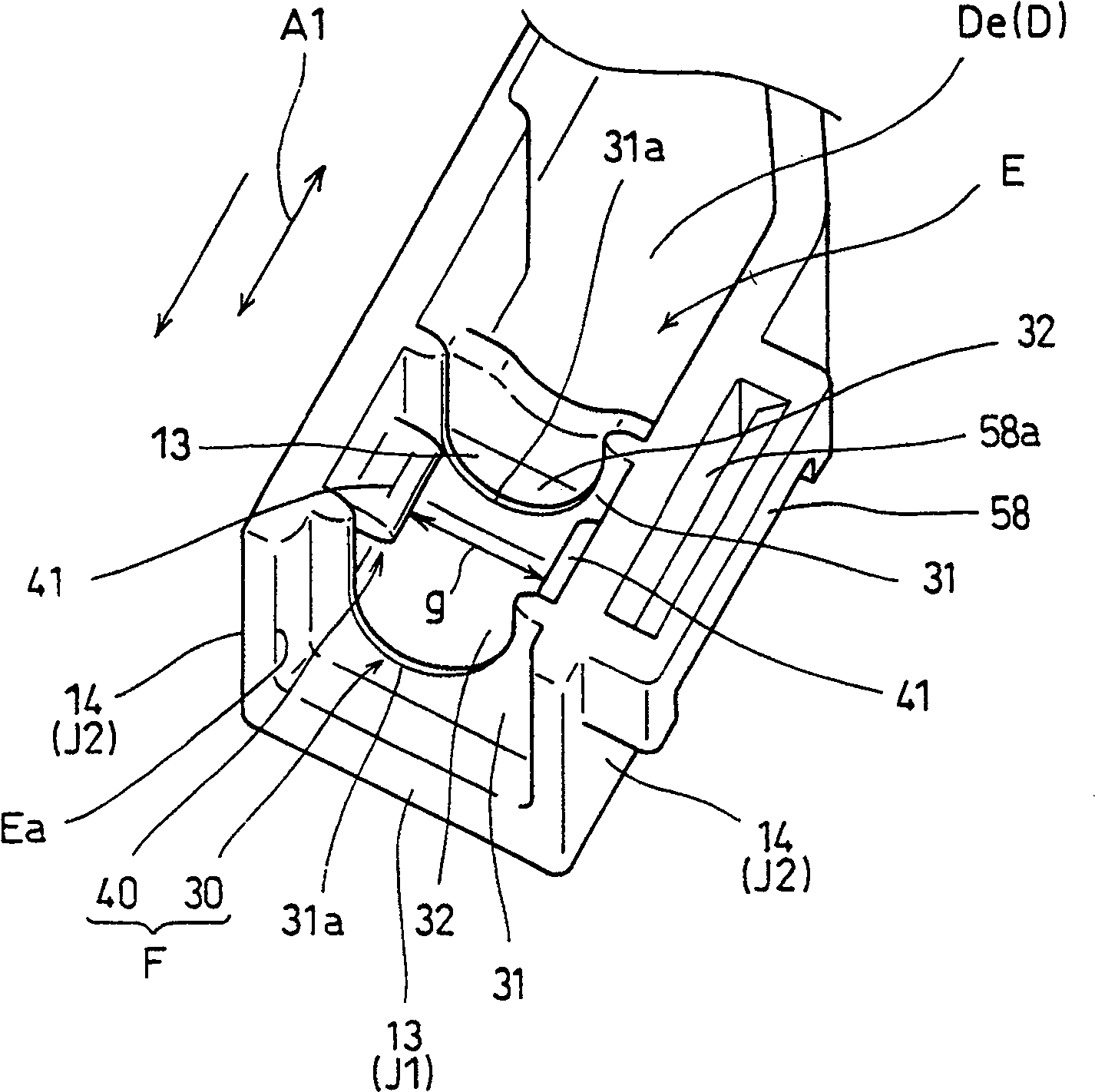

[0047] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0048] refer to figure 1 , in a preferred embodiment of the present invention, the wire harness group including the wire harness W is an automotive wire harness group to be provided in a vehicle having a multi-cylinder internal combustion engine. The wire harness W includes a plurality of protective holders H1 to H7 and a clip N. As shown in FIG. The protective holders H1 to H7 and the clip N are attached to objects such as an internal combustion engine and a vehicle body, thereby mounting the wire harness set on the vehicle.

[0049] The wire harness W interconnects electrical and electronic devices including a battery, an electronic control unit ("ECU"), a plurality of sensors including a crank angle sensor and an air / fuel ratio sensor, and indicators including a speedometer. The air / fuel ratio sensor described above detects physical quantities representing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com