Piezoelectric hydraulic pump

A hydraulic pump and piezoelectric technology, applied in the field of hydraulic pumps, can solve the problems of difficult manufacturing, high cost, and small power-to-mass ratio, and achieve the effects of no electromagnetic interference, simple structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

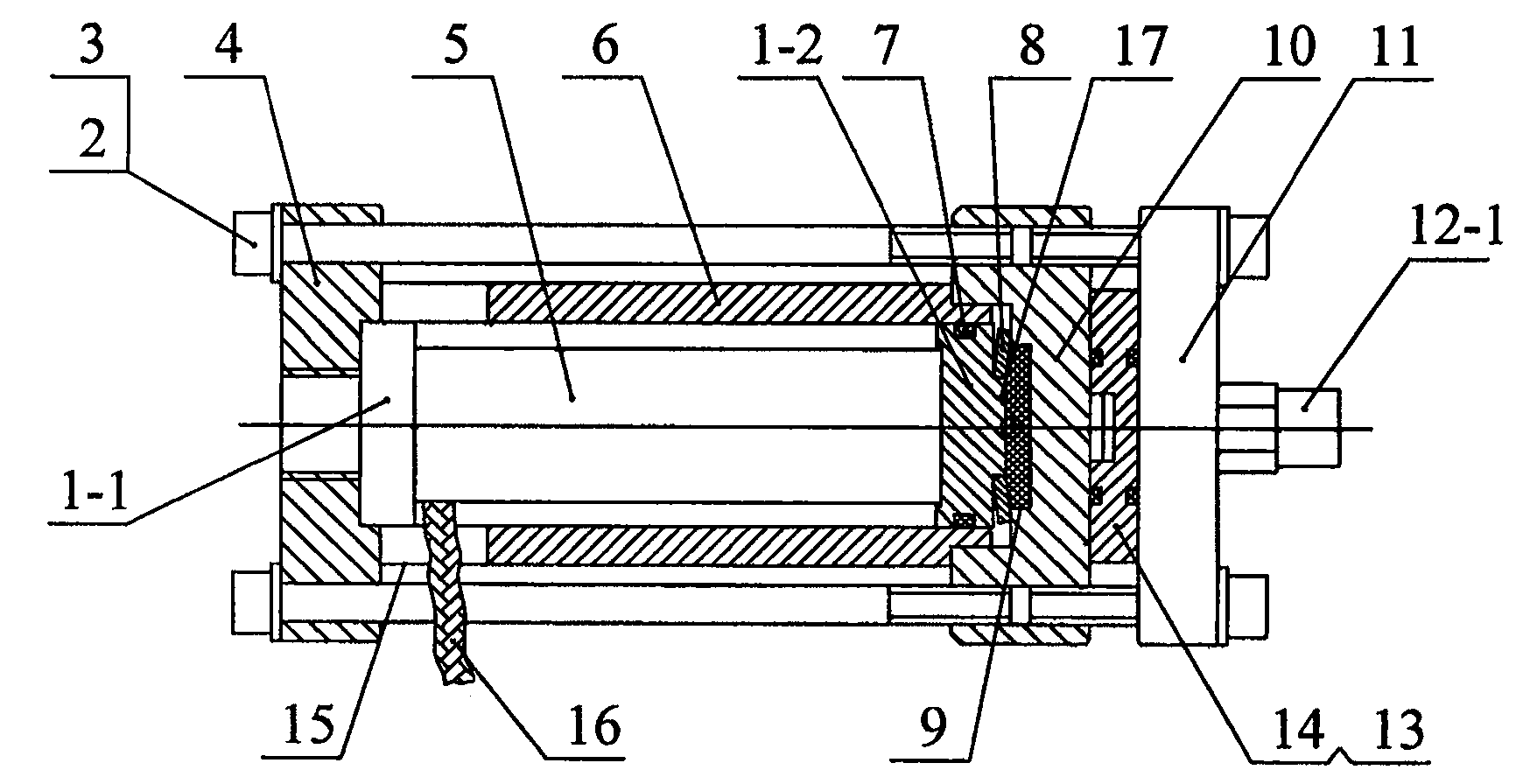

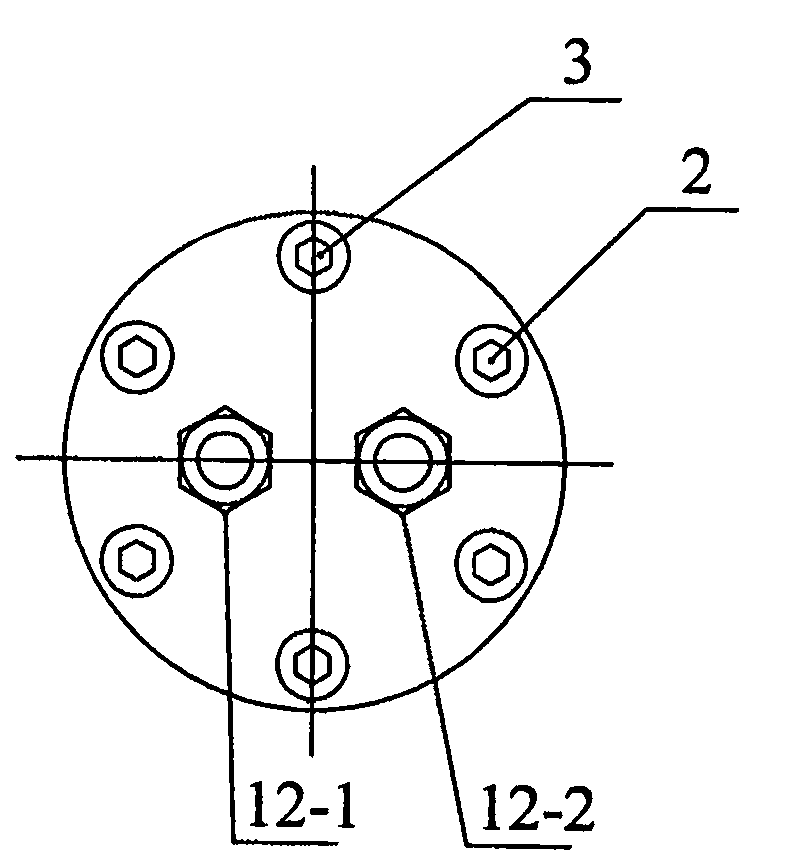

[0007] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment consists of a first guide block 1-1, a second guide block 1-2, a hexagon socket head cap screw 2, a left end cover 4, a piezoelectric actuator 5, a cylinder body 6, an O-ring 7, a disc spring 8, Right end cover 10, cover plate 11-, oil inlet pipe joint 12-1, oil outlet pipe joint 12-2, oil inlet valve 13 and oil outlet valve 14, the first guide block 1-1 is set at the left end of the cylinder body 6 cavity 1. The second guide block 1-2 is located at the right end in the cylinder block 6 cavity, and the right end surface of the second guide block 1-2 is provided with a boss 17, and the disk spring 8 is fixed on the boss 17, and the second guide block The outer ring of 1-2 is provided with an O-ring 7, the piezoelectric actuator 5 is located in the cavity of the cylinder body 6, the left end surface of the first guide block 1-1 is embedded in the right end surface...

specific Embodiment approach 2

[0008] Embodiment 2: In this embodiment, the left end of the cylinder body 6 is provided with a cable groove 15, and the piezoelectric cable 16 is connected to a power source.

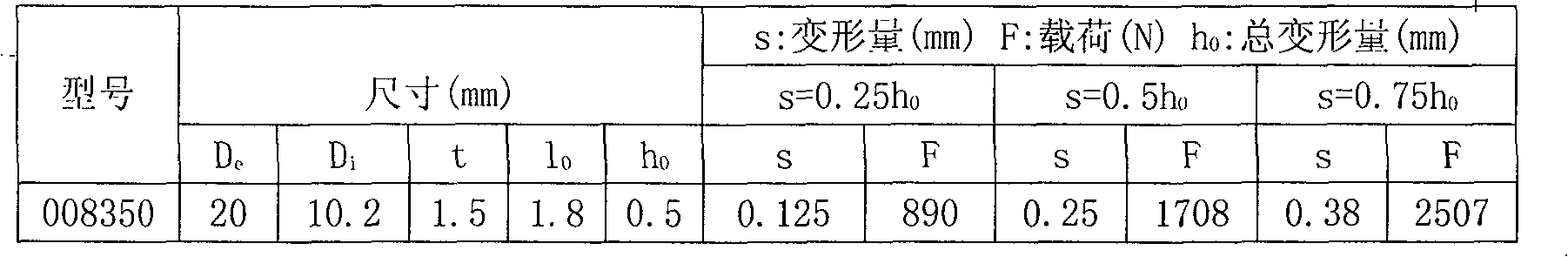

[0009] In the present invention, disc springs 8 are arranged on the boss 17 of the second guide block 1-2, and a sealed cavity 9 is formed on the right end surface of the second guide block 1-2 and the middle recess at the left end of the right end cover 10. When the system pressure exceeds Working pressure, liquid will overflow from the contact surface of disc spring 8 and right end cover 10, plays the effect of safety valve. Because the spring strain has a good linear relationship with the load, it can also improve the dynamic characteristics of the system, so that the piezoelectric actuator 5 can obtain a larger amplitude and increase the output flow of the piezoelectric hydraulic pump.

[0010] working principle:

[0011] Using the inverse piezoelectric effect of piezoelectric materials, when an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com