A Micropump Device Driven by Photostrictive Material

A light-driven, micro-pump technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve problems affecting precise control, weak driving ability, small electrostatic driving force, etc., to avoid electromagnetic noise interference, Simple and compact structure, easy to output flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

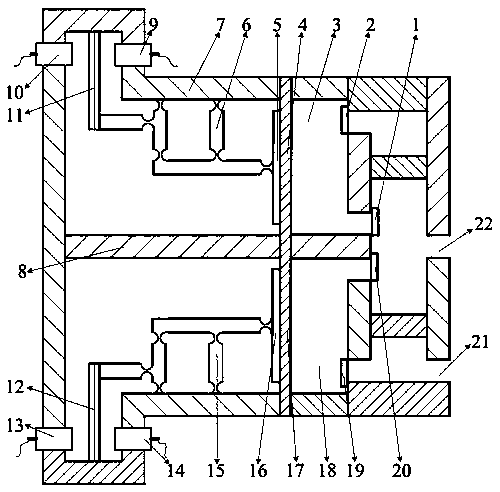

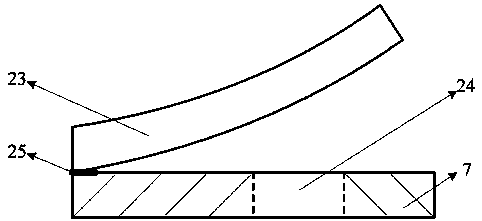

[0016] combine figure 1 , a light-driven micro-pump device of the present invention includes an upper pump, a lower pump, an upper pump driving amplifying mechanism, a lower pump driving amplifying mechanism, a pump body 7, a water outlet 22 and a water inlet 21, and the middle of the pump body 7 is provided with There is a pump body center plane 8, the pump body center plane 8 is located on the central axis of the pump body 7, the upper pump is located above the pump body center plane 8, the lower pump is located below the pump body center plane 8, and the upper pump is driven to enlarge The mechanism is connected with the upper pump membrane cover 5 of the upper pump, and is used to drive the upper pump to realize pumping water. The lower pump driving amplifying mechanism is connected with the lower pump membrane cover 16 of the lower pump, and is used to drive the lower pump to realize pumping water, wherein the upper pump and The lower pump has the same structure and is sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com