Two-thread vertical thread feeding device

A vertical, wire-feeding technology, applied in the field of double-wire vertical wire-feeding devices, which can solve problems such as the inability to keep the cored wire vertically entering the bottom of the ladle, long distance, and inability to guarantee the treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

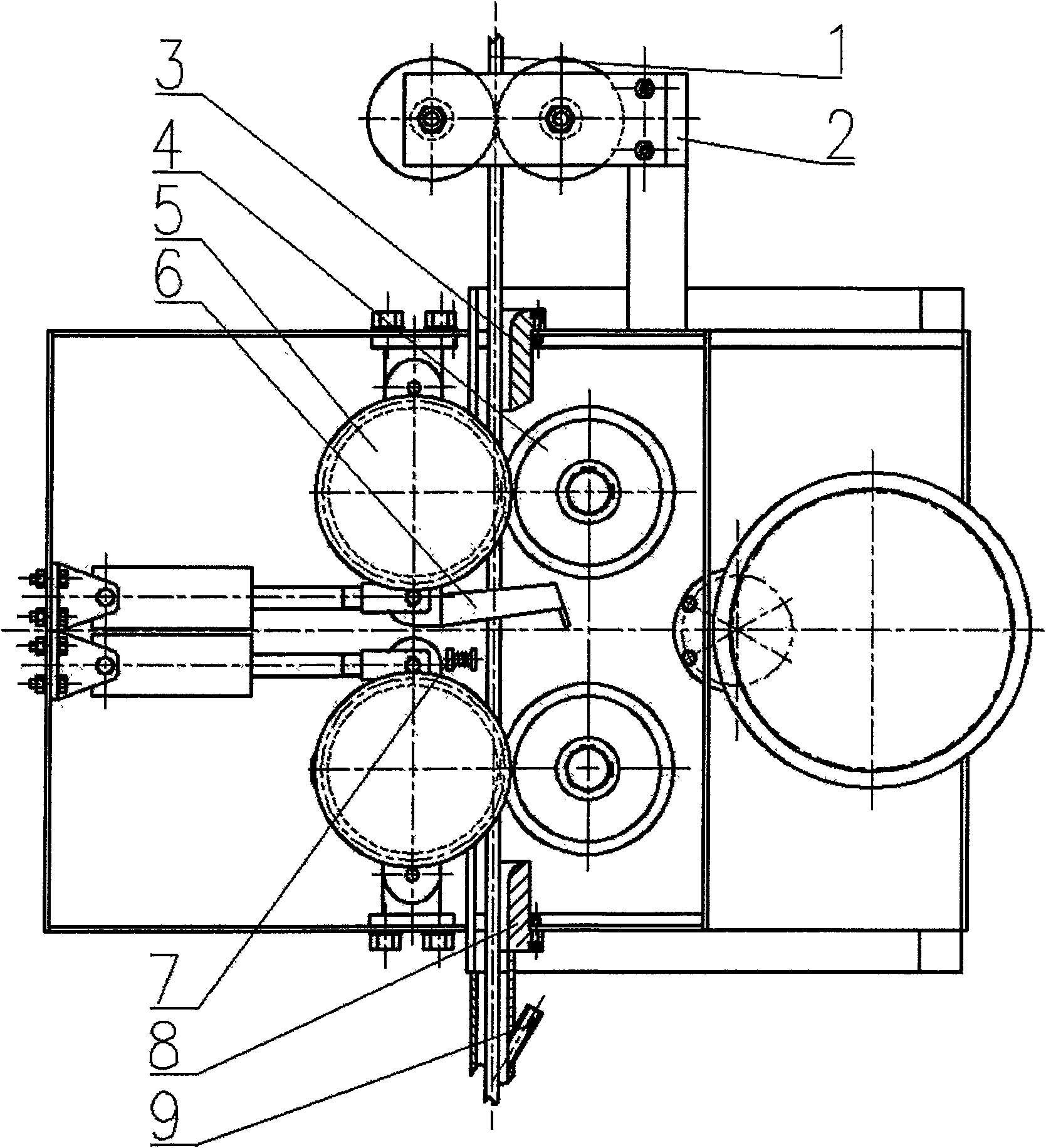

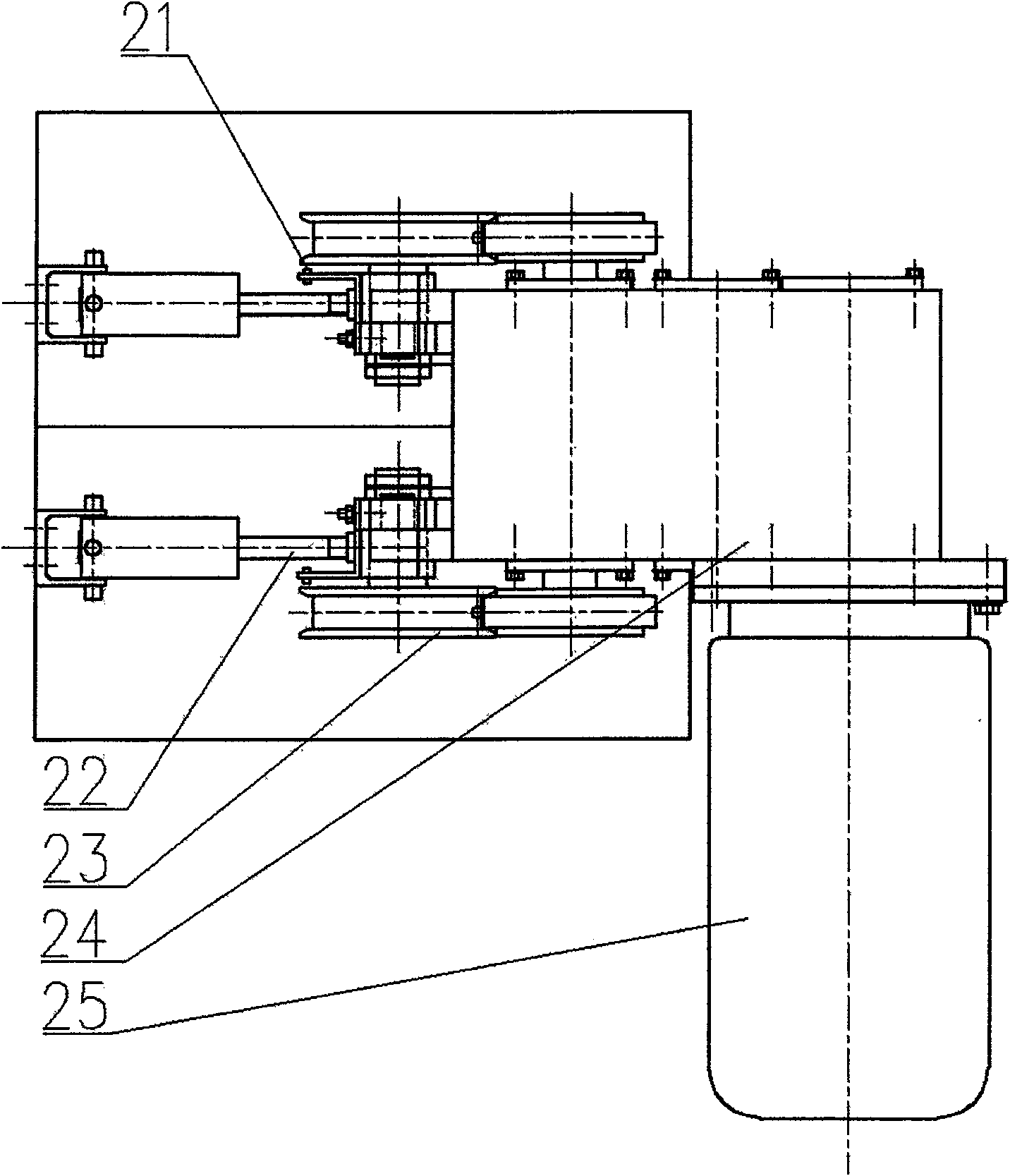

[0014] The above-mentioned devices are mainly the core-spun wire guiding device, the double-wire vertical wire feeding machine and the calculation input control unit. Referring to the accompanying drawings, the double-wire vertical wire feeding device includes two wire feeding channels. After the cored wire is pulled out from the inner-drawing type cored wire roll, it first passes through 9-15 cored wire guiding devices before entering the double-wire vertical wire reel. The wire inlet conduit of the type wire feeding machine reaches the wire outlet conduit after passing through two sets of active drive wheels and passive drive wheels, and enters the conduit of the equipment.

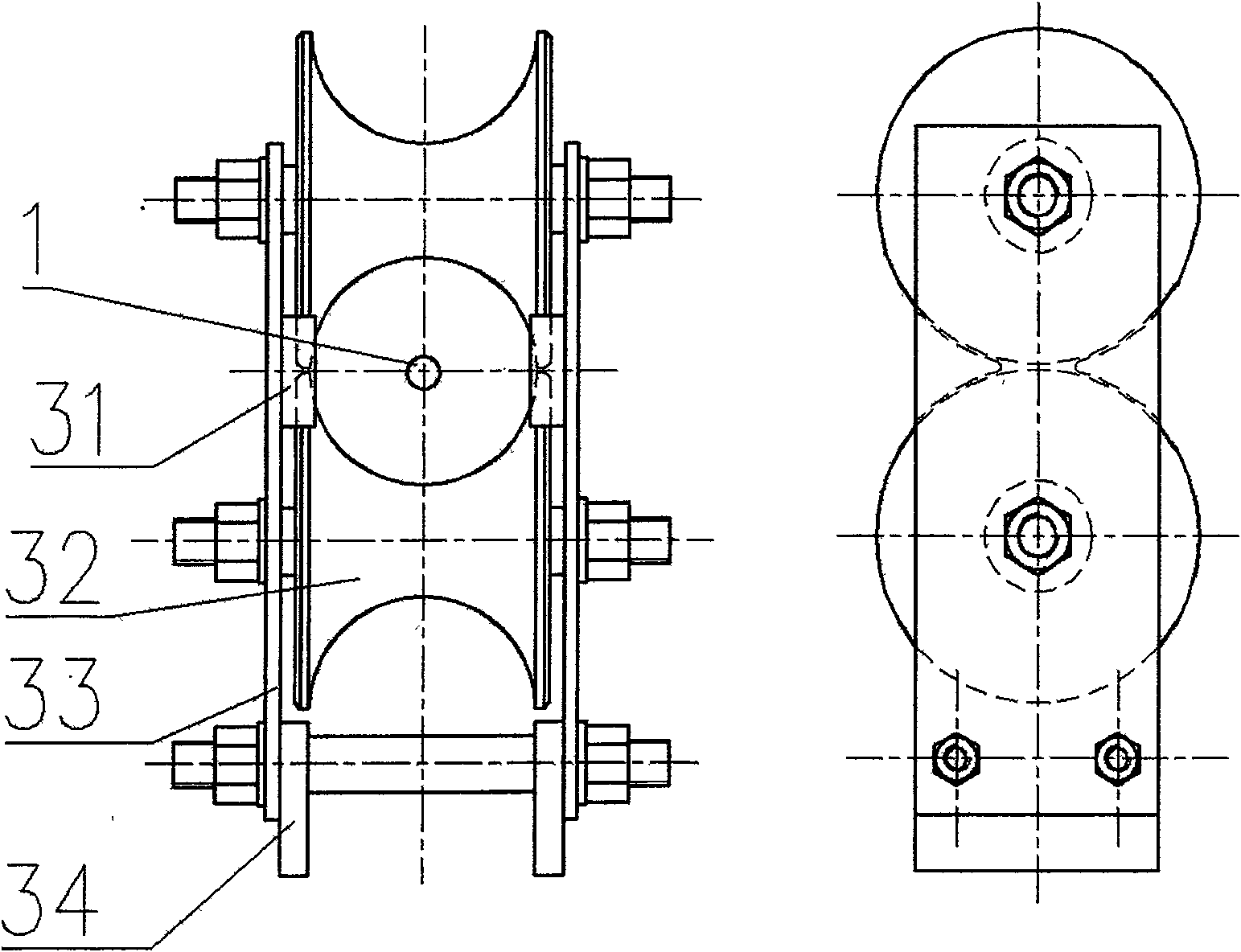

[0015] Core wire guide ( image 3 ) is mainly made up of two rotatable concave wheels 32, block 31, side plate 33, mounting plate 34. Bearing is installed in concave wheel 32, is easy to rotate. Block 31 is in order to prevent that cored wire is clamped in the gap of two concave wheel edges. The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com