Deep water full-automatic hydraulic drawing pretension position compensating fixed-moment wrench

A fully automatic, constant torque technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as complex stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

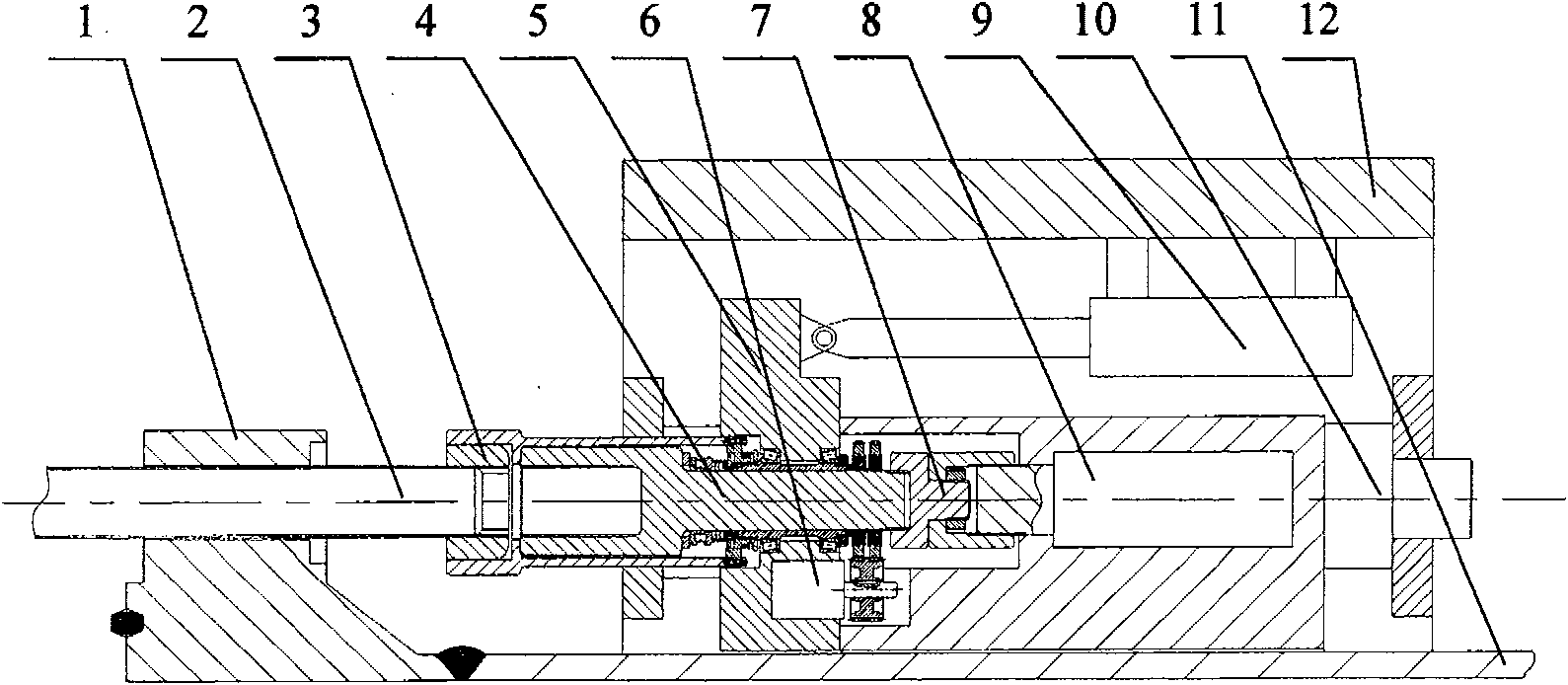

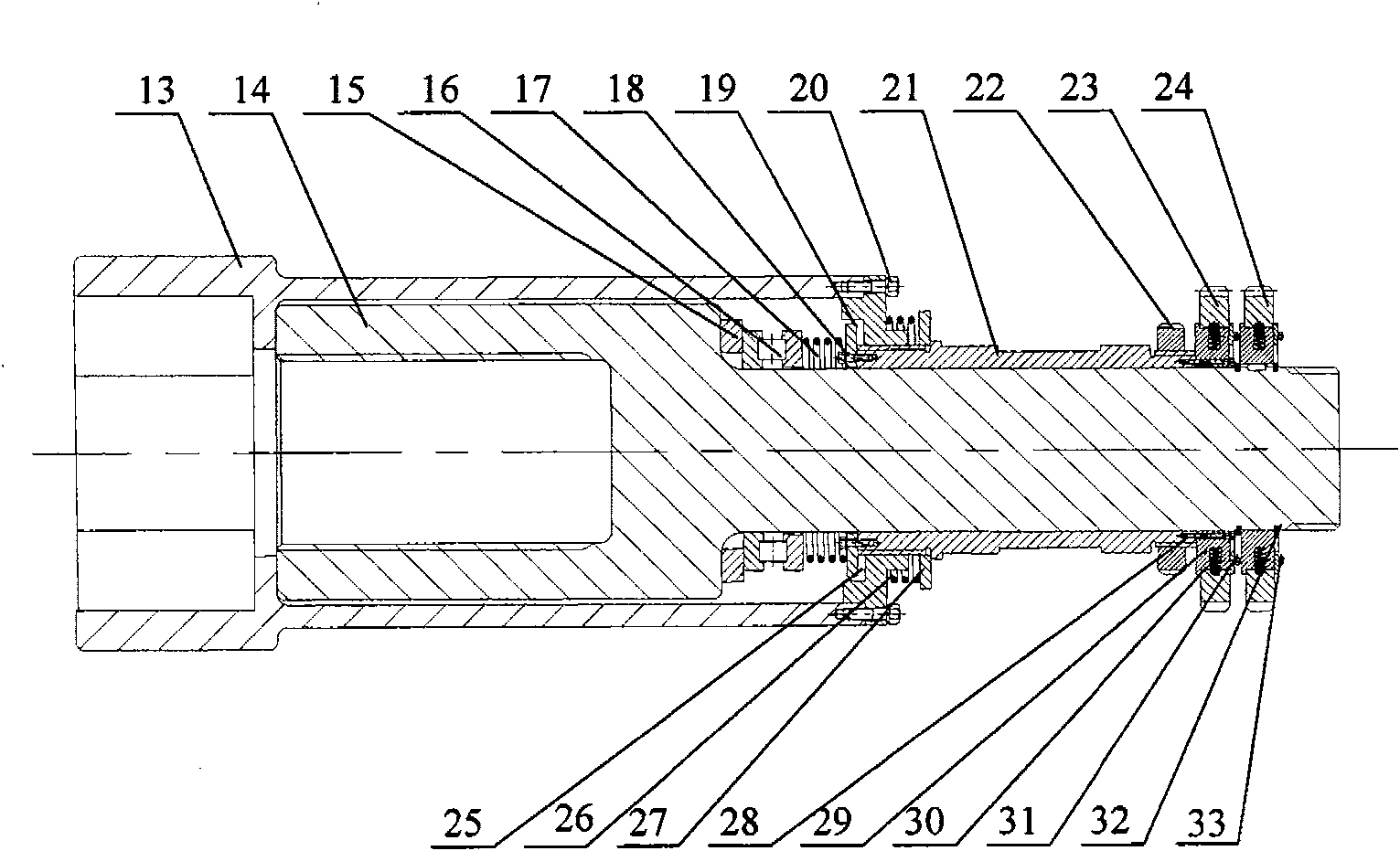

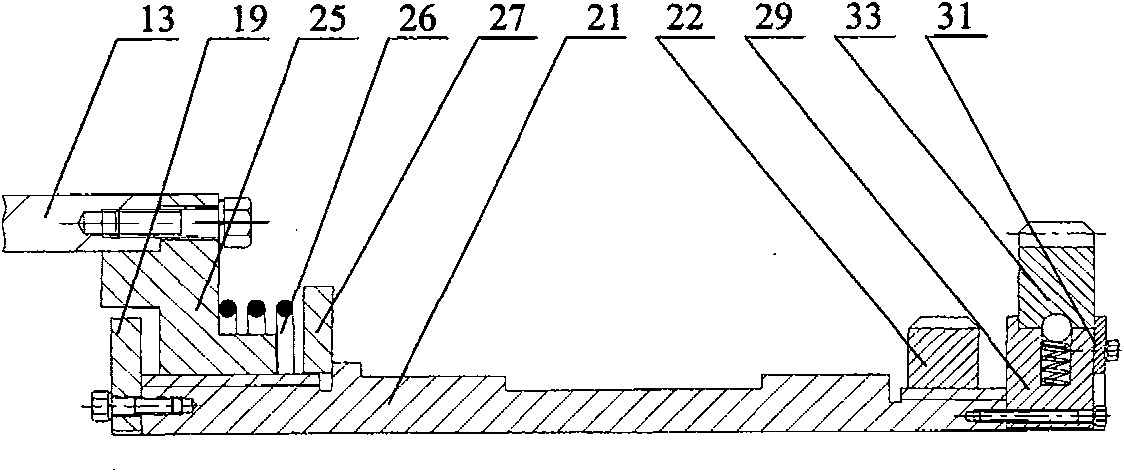

[0025] combine figure 1 , The main components of the deep-water fully automatic hydraulic tension pretension position compensation constant torque wrench include: fixed flange 1, bolt 2, nut 3, tension wrench 4, wrench seat 5, hydraulic motor 6, coupling 7, hydraulic cylinder 8. Hydraulic cylinder 9, guide shaft 10, pipeline 11, hole regulator 12. The wrench system is installed on the side of the nut store, and the upper mechanism of the device is the hole adjuster of the nut store. The function of the hole adjuster is to align the central axis of the wrench with the bolt axis after the nut bank is positioned on the pipeline. figure 1 Among them, the fixed flange 1 is welded on the pipe 11 and corresponds to the movable flange (rotary ring flange) on the other side. After the bolt holes of the fixed flange and the movable flange are aligned, insert 16 M90 bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com