Full-automatic spray type device for preparing film

A fully automatic spraying and fully automatic technology, applied in the coating and other directions, can solve the problems of inability to control the film thickness well, difficult to precisely control the preparation time, and inability to obtain a good shape, etc., to achieve high precision, save labor, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

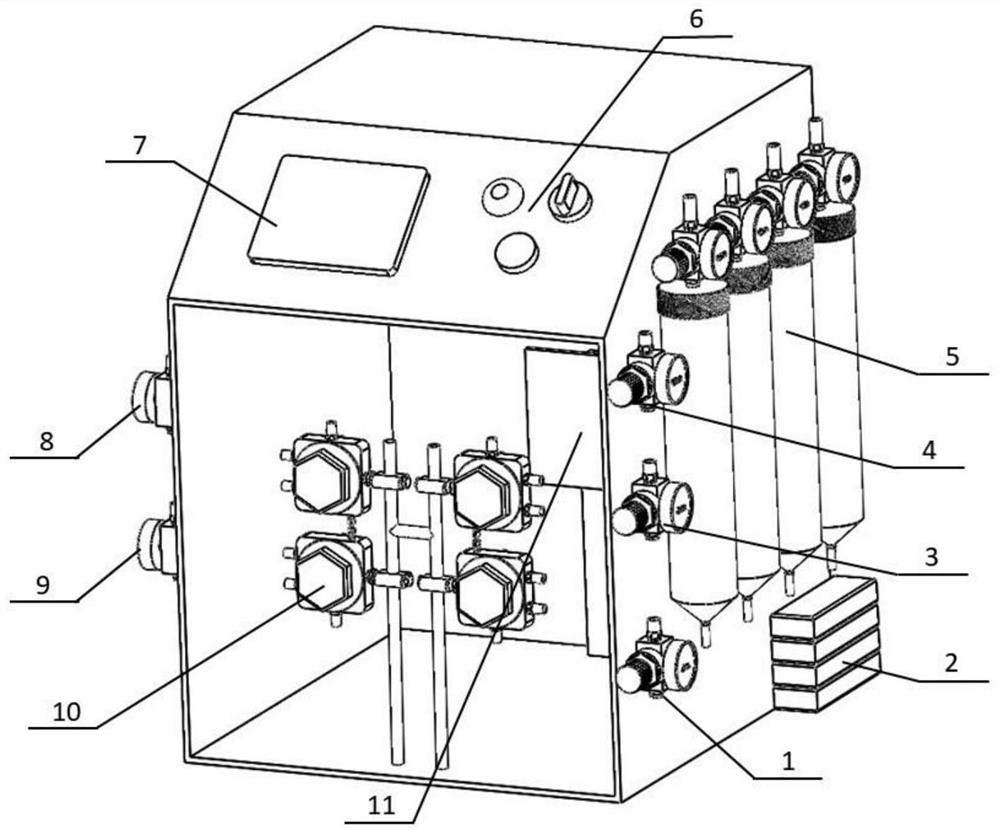

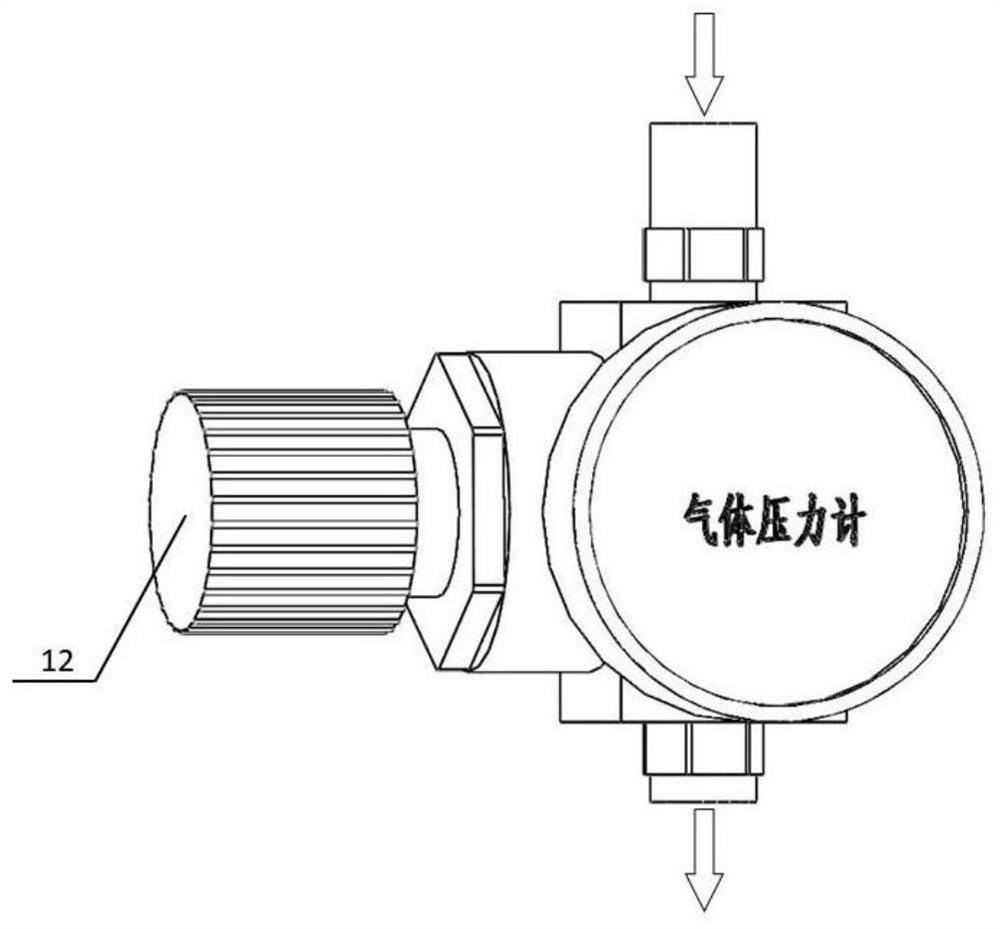

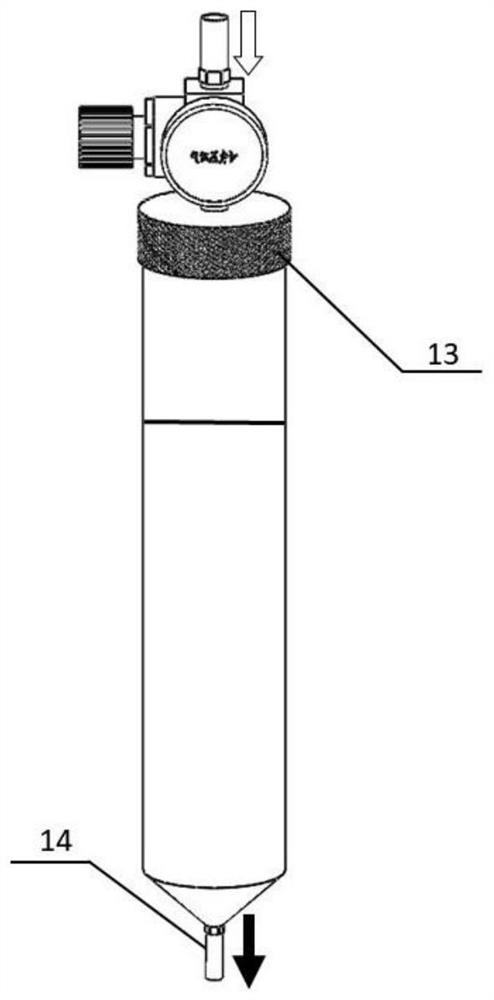

[0071] The invention provides a device for fully automatic spraying film preparation, which includes a gas supply system, a gas regulating system, a pressure vessel, a numerical control system, an atomizing nozzle, a base support frame and an external box. The schematic diagram of the device is as figure 1 As shown, the working principle diagram is attached Figure 8 shown. The atomizing nozzle and the base support frame are located inside the box and directly participate in the spraying and film formation; the rest should avoid direct contact with the spray and can be arranged outside and above the box.

[0072] In order to facilitate the operation of the internal device, one side of the external box is made of metal, and the other side is made of transparent PMMA plastic. There is also a push-pull door to facilitate the adjustment of parameters such as the placement of the base and the angle of the bracket at any time.

[0073] Liquid conduit arrangement: The liquid condui...

Embodiment 2

[0079] The metal-organic framework (taking the classic HKUST-1 as an example) thin film is prepared by using the device described in Example 1 above, and the device is selected according to the laboratory with a smaller size such as 50*50*50cm (length / width / height) , while the gas supply system uses a standard pure nitrogen cylinder, which specifically includes the following steps:

[0080] Prepare raw material solutions: weigh copper acetate and trimesic acid, dissolve them in pure ethanol solutions, and prepare 500 mL of ethanol solutions with concentrations of 1 mmol / L and 0.4 mmol / L respectively.

[0081] Preparation stage: Pour the prepared copper acetate ethanol solution and trimesic acid ethanol solution into container 1 and container 2 in sequence, container 4 contains 500mL of alcohol (for rinsing the substrate), container 3 is empty, container 1- 4 are made of stainless steel. Set the program through the console of the numerical control system: copper acetate ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com