Human vola-emulated mechanism with force-sensing ability

A technology of perceptual ability and sole, applied in toys, motor vehicles, automatic toys, etc., can solve the problem of neglecting the movement function of the toe joint, and achieve the effect of light weight, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

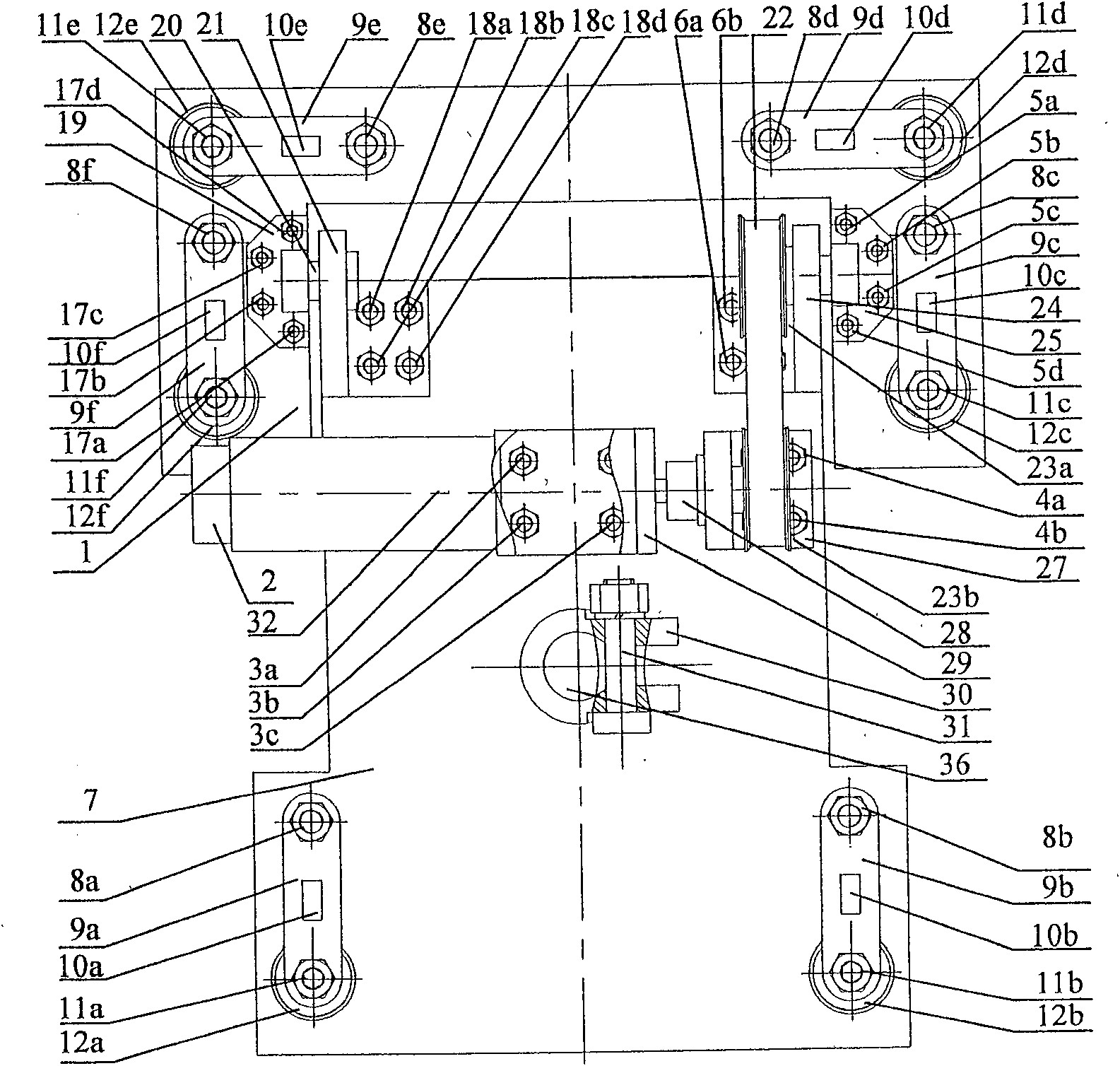

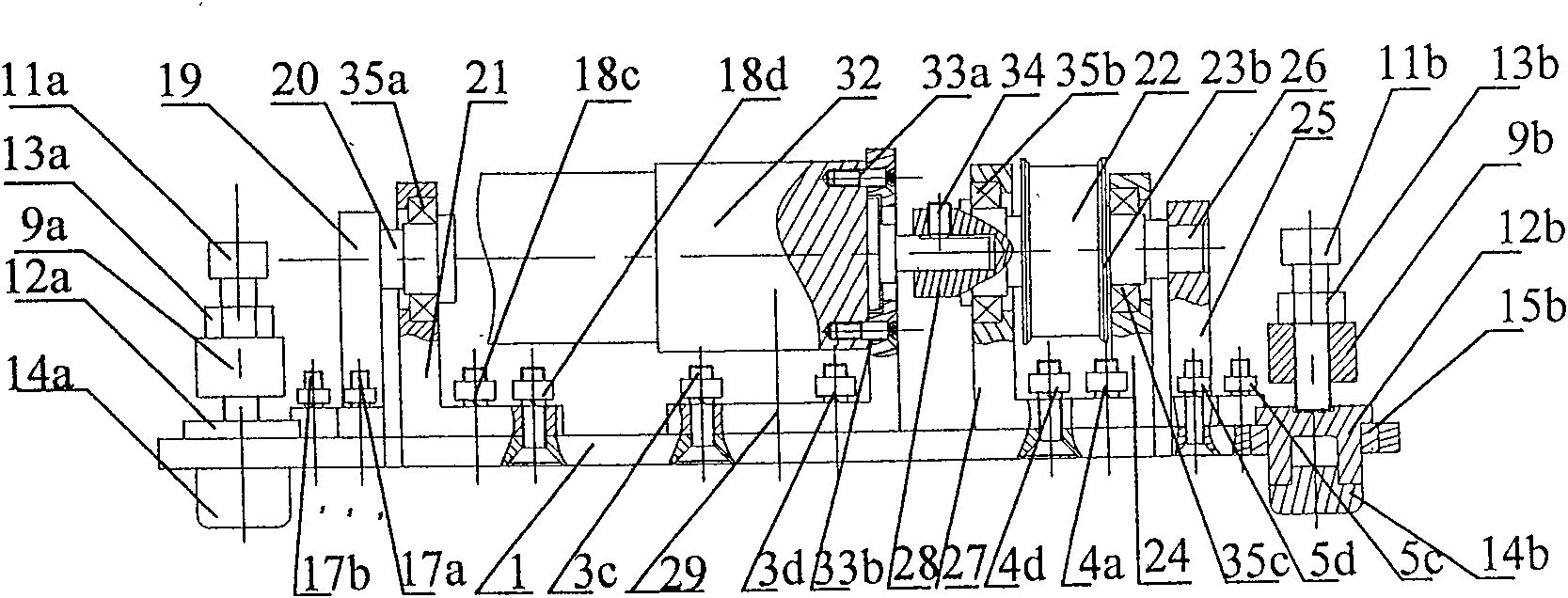

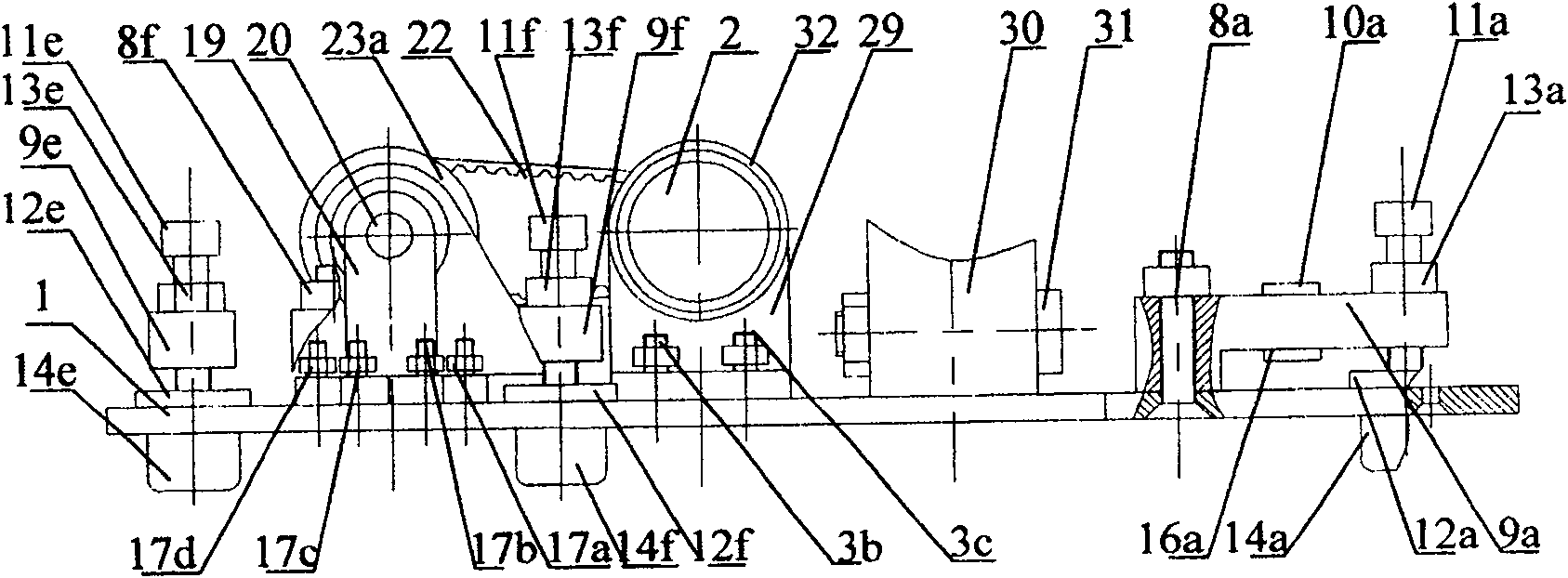

[0029] to combine Figure 1-3 , this embodiment includes a forefoot 1, a rear foot 7, six force-sensing detection components, a rotating shaft connecting the forefoot and the rear foot and related transmission components, and the forefoot 1 has four force-sensing detection components c, d, e , f, four force-sensing detection components are symmetrically distributed on the outermost edge of the support surface; the rear foot 7 has two force-sensing detection components a, b and a connection end seat 36 connected to the ankle joint, wherein two The force-sensing detection components a and b are symmetrically distributed on the rear side edge of the rear foot 7, and the connecting end seat 36 and the ankle joint tightening ring 30 are tightly connected by bolts 31; the structures of the six force-sensing detection components are all Similarly, in order to avoid unnecessary repetition, a force-sensing detection component b is described, and the force-sensing detection component b ...

Embodiment 2

[0035] combine Figure 4 , 5 and 6, the present embodiment makes certain changes on the basis of embodiment 1, specifically, the timing belt 22 connecting the gears 23a and 23b in the embodiment 1 is removed, and the gears 23a and 23b are replaced with gears 37a and 37b, the synchronous belt transmission of the original embodiment 1 is replaced by the gear transmission in which the gears 37a and 37b mesh, and the others are the same as in the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com