Gas drying device

A gas drying and gas technology, applied in the field of drying compressed gas devices and drying gas devices, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

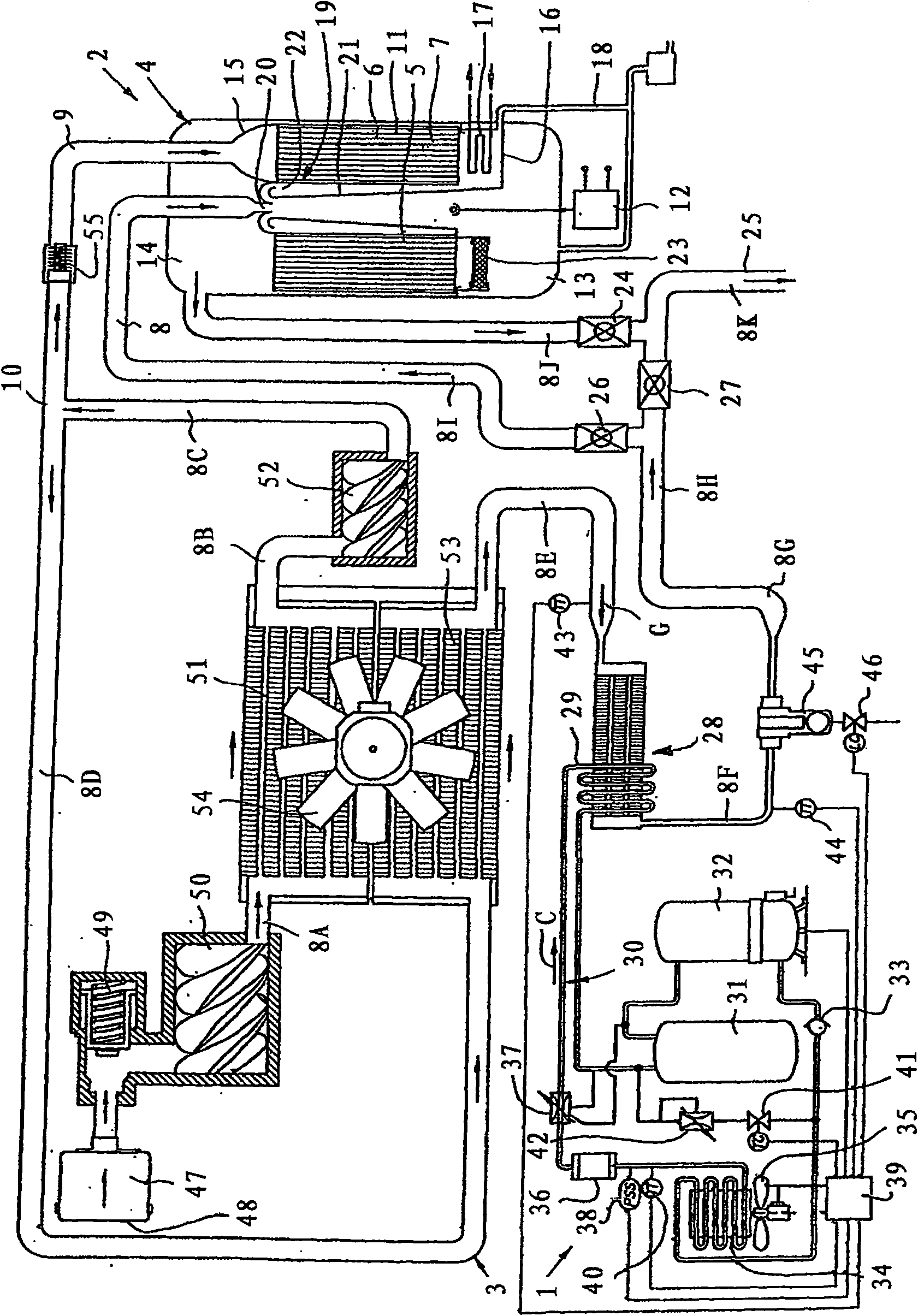

[0012] Such as figure 1 As shown, the gas drying device essentially comprises a cooling dryer 1 , a desiccant dryer 2 and in this embodiment also a compressor part 3 .

[0013] The desiccant dryer 2 is of the type utilizing a pressure tank 4 having a drying zone 5 and a regeneration zone 6 containing an adsorption and / or absorption medium 7 which is led alternately through the drying zone 5 and regeneration zone 6 .

[0014] Furthermore, the device comprises a primary circuit 8 comprising pipes with sections 8A, 8B, 8C, 8D, 8E, 8F, 8G, 8H, 8I, 8J and 8K, the aforementioned cooling dryer 1, the desiccant dryer 2 and the aforementioned The compressor part 3 is integrated into this primary circuit 8 , which makes it possible to first compress the gas to be dried, then at least partially dry it in the cooling dryer 1 and then lead it through the desiccant dryer 2 The drying zone 5 is further dried.

[0015] The device also comprises a secondary circuit 9 which, as a branch 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com