In-situ polymerization process for preparing polyaniline composite hyperfiltration membrane

An in-situ polymerization, polyaniline technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

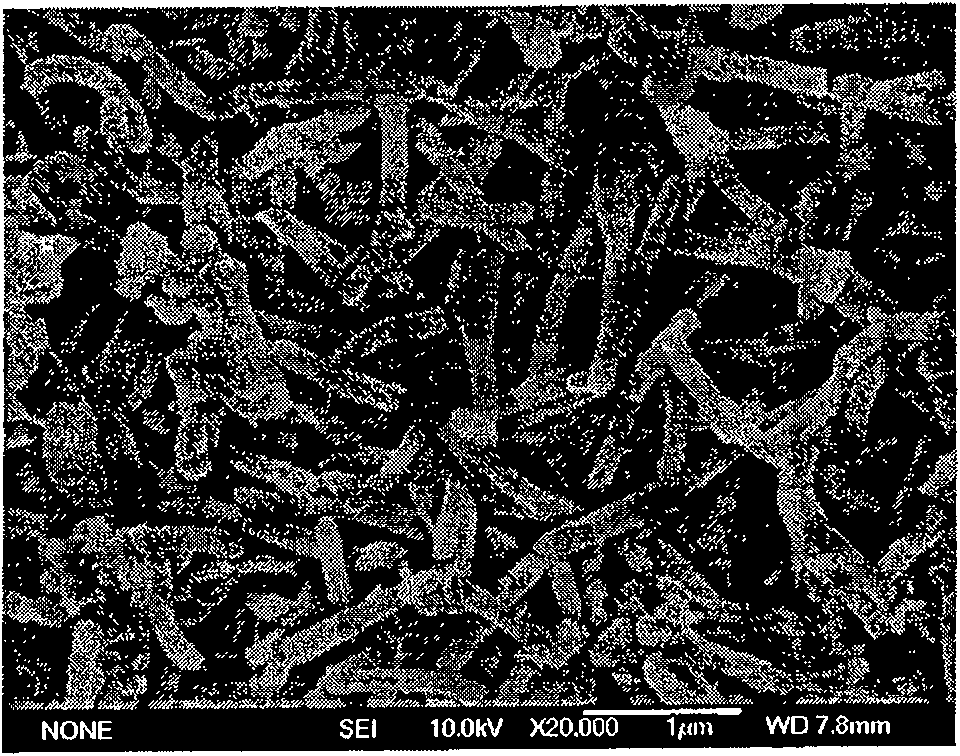

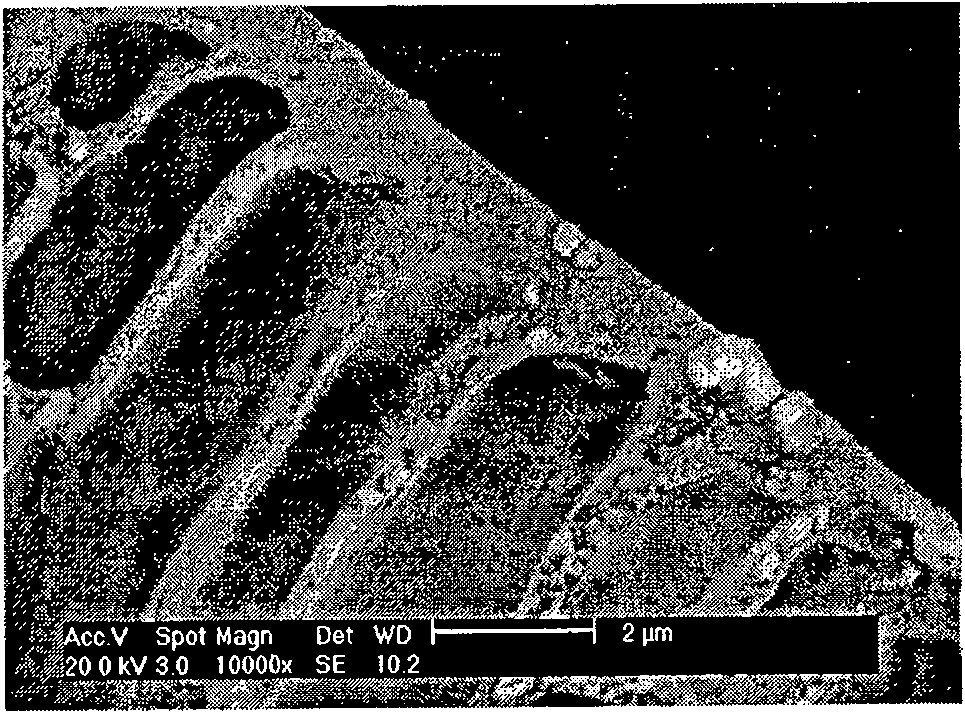

[0013] Weigh 0.35g of surfactant sodium dodecylbenzenesulfonate at a temperature of 25°C, place in 200mL of deionized water and adjust the pH to 2.3 with citric acid, then weigh 1.7mL of aniline, and add it to the above solution, Stir at 100rpm to dissolve, add 16×8cm 2 The polysulfone membrane was stirred for 4 hours, and then stirred for 2 hours at 5 °C. Then weigh 4.25g of ammonium persulfate, dissolve it in a small amount of deionized water, add it to the above solution with polysulfone membrane, stir for 10 minutes, and react at 0-5°C for 24 hours. After the reaction is completed, the polyaniline composite ultrafiltration membrane is taken out, washed with anhydrous methanol, hydrochloric acid with a mass concentration of 36%, and deionized water to obtain a finished polyaniline composite ultrafiltration membrane. The prepared polyaniline composite ultrafiltration membrane was tested at 0.16MPa, and the pure water flux was 27L / m 2 h, the rejection rate of 50ppm PEG35K a...

Embodiment 2

[0015] Weigh 0.7g of surfactant sodium dodecylbenzenesulfonate at a temperature of 25°C, place it in 200mL of deionized water and adjust the pH to 2.3 with citric acid, then weigh 3.4mL of aniline and add it to the above solution, Stir at 100rpm to dissolve, add 16×8cm 2 The polysulfone membrane was stirred for 4 hours, and then stirred for 2 hours at 5 °C. Then weigh 8.50 g of ammonium persulfate, dissolve it in a small amount of deionized water, add it to the above solution with polysulfone membrane, stir for 10 minutes, and then react at a temperature of 0-5° C. for 24 hours. After the reaction is completed, the polyaniline composite ultrafiltration membrane is taken out, washed with anhydrous methanol, hydrochloric acid with a mass concentration of 36%, and deionized water to obtain a finished polyaniline composite ultrafiltration membrane. The prepared polyaniline composite ultrafiltration membrane was tested at 0.16MPa, and the pure water flux was 17L / m 2 h, the reject...

Embodiment 3

[0017] Weigh 0.12g of surfactant sodium dodecylbenzenesulfonate at a temperature of 25°C, place it in 200mL of deionized water and adjust the pH to 2.3 with citric acid, then weigh 0.6mL of aniline, and add it to the above solution, Stir at 100rpm to dissolve, add 16×8cm 2 The polysulfone membrane was stirred for 4 hours, and then stirred for 2 hours at 5 °C. Then weigh 1.42g of ammonium persulfate, dissolve it in a small amount of deionized water, add it to the above solution with polysulfone membrane, stir for 10 minutes, and react at 0-5°C for 24 hours. After the reaction is completed, the polyaniline composite ultrafiltration membrane is taken out, washed with anhydrous methanol, hydrochloric acid with a mass concentration of 36%, and deionized water to obtain a finished polyaniline composite ultrafiltration membrane. The prepared polyaniline composite ultrafiltration membrane was tested at 0.16MPa, and the pure water flux was 46L / m 2 h, the rejection rate of 50ppm PEG35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com