Drive device for lock pin

A driving device and lock cylinder technology, used in construction locks, non-mechanical transmission-operated locks, construction, etc., can solve the problems of inability to integrate, difficult, complex electromechanical structure, etc., to improve reliability, service life, driving stroke, etc. Small, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

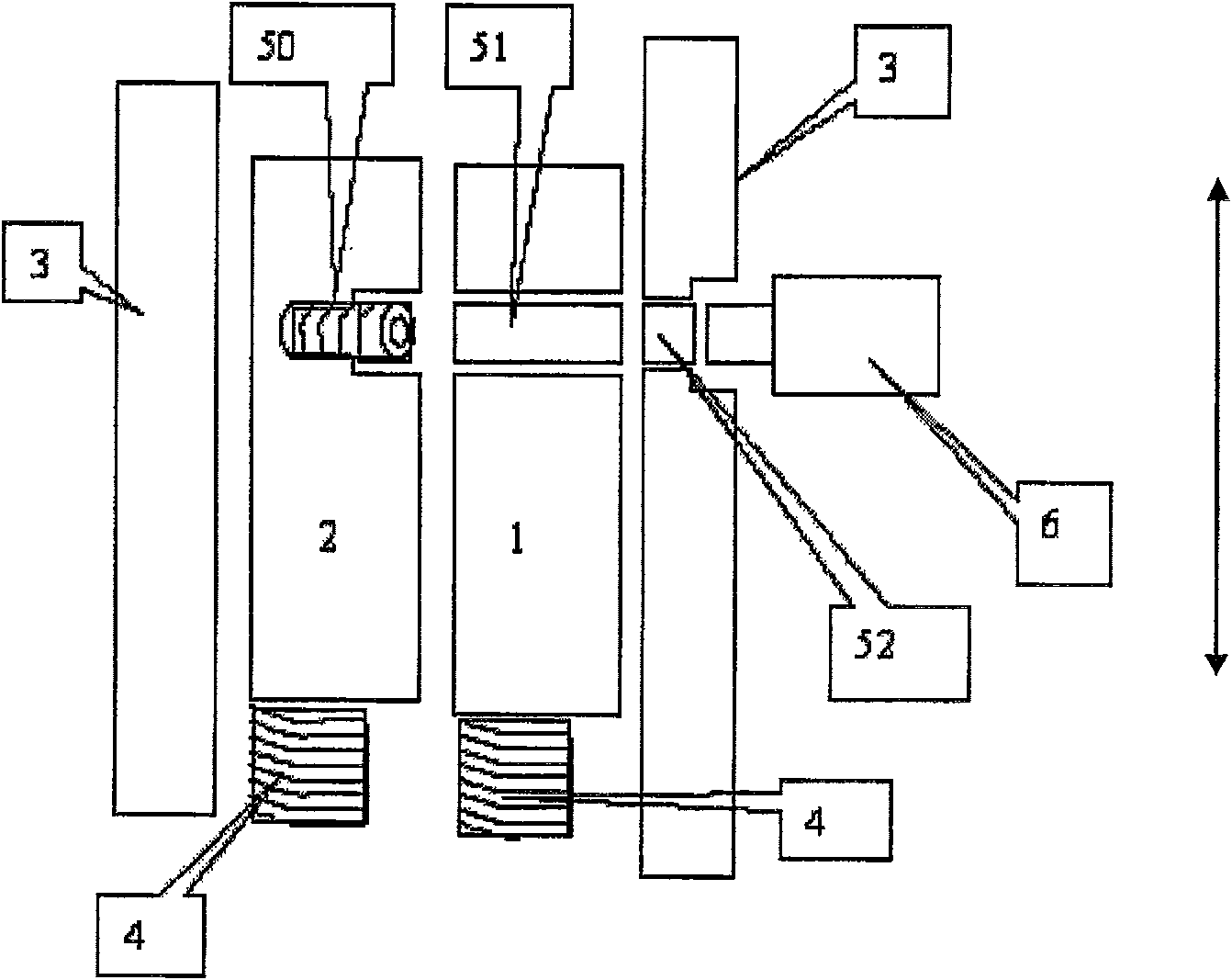

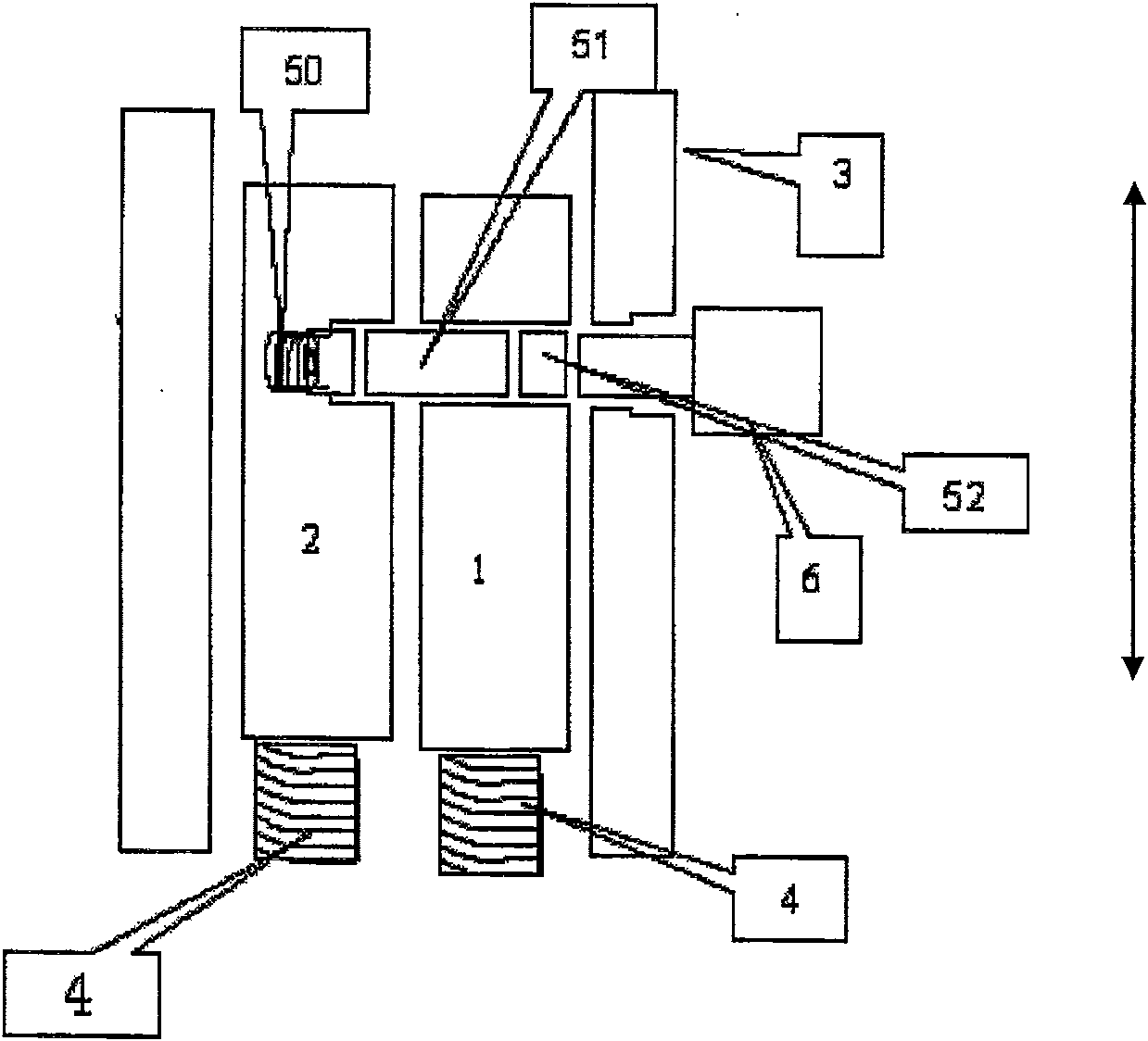

[0050] Embodiment one: if Figure 17 As shown, it is a structural diagram of a pair of back-up driving devices. The bracket 62 is in the shape of a "day" and is fixedly connected to the drive output shaft 61. In each frame of the bracket, there is an ornament 63 that abuts against the inner wall of the frame. The ornament and The output shaft of the micro-motor is connected, and the shape of the pendulum is not limited, as long as the bracket can be pressed under the drive of the micro-motor, so that the drive output shaft 61 can move axially under the guidance of the through hole or other components.

Embodiment 2

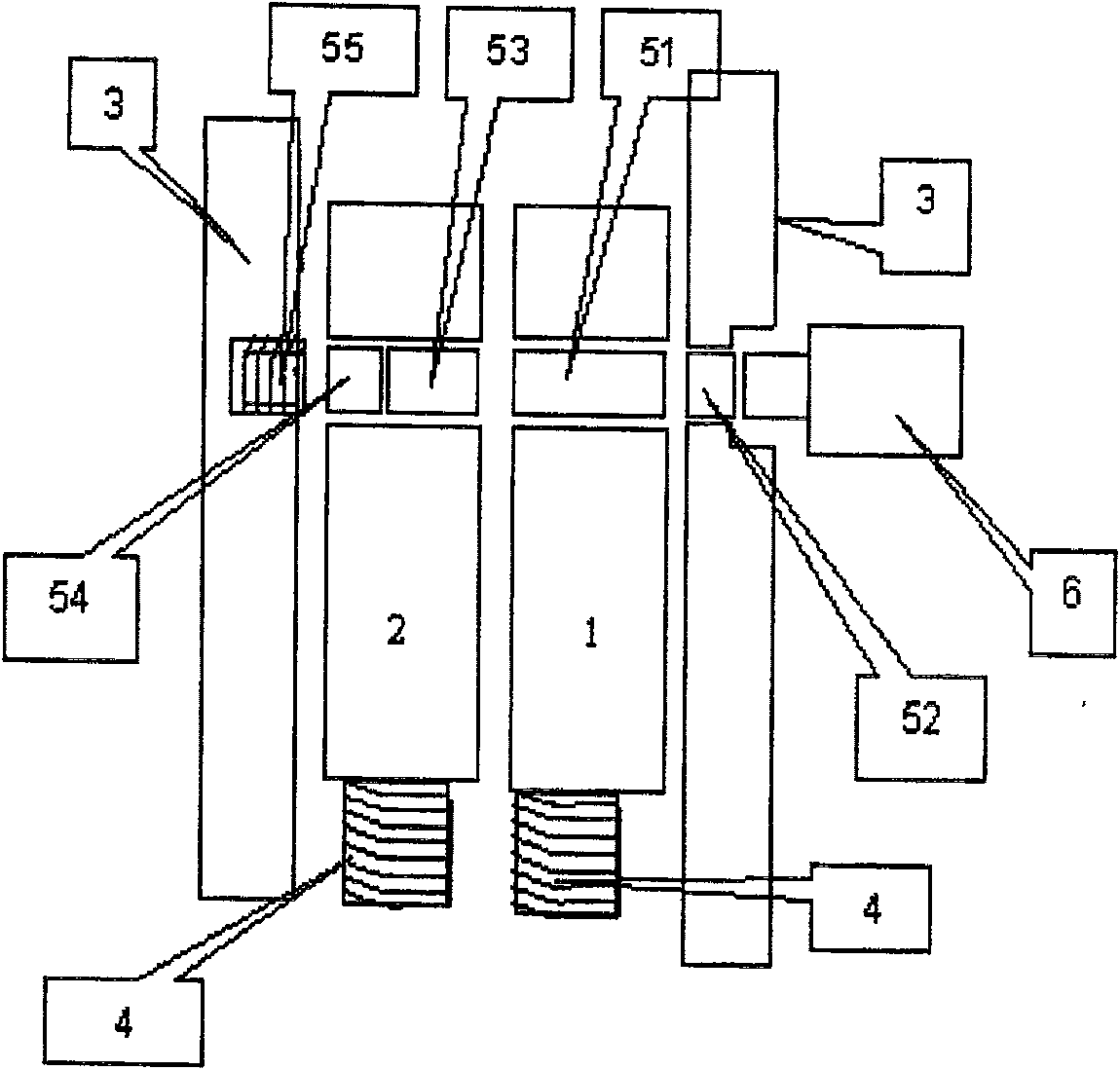

[0051] Embodiment two: if Figure 18 shown in Figure 17 The second drive output shaft 64 is set on the opposite direction of the drive output shaft, which is opposite to the direction of motion of the drive output shaft 61. In applications, one drive command produces two opposite drive output actions. This mechanism can applied as Figure 23 In the system shown, special control requirements are met, such as a command is generated simultaneously: one locking action, one separation action; or two locking actions; or two separation actions.

Embodiment 3

[0052] Embodiment three: as Figure 19 As shown, it is a driving device using another shape of the pendant, the principle is the same as Figure 17 The drives shown are identical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com