Motor and its stator structure

A motor stator and stator technology, applied in the field of motors, can solve the problems of reducing the rotational torque of the rotor and reducing the induction area of the permanent magnet, and achieve the effects of increasing the magnetic flux, increasing the area, and increasing the induction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

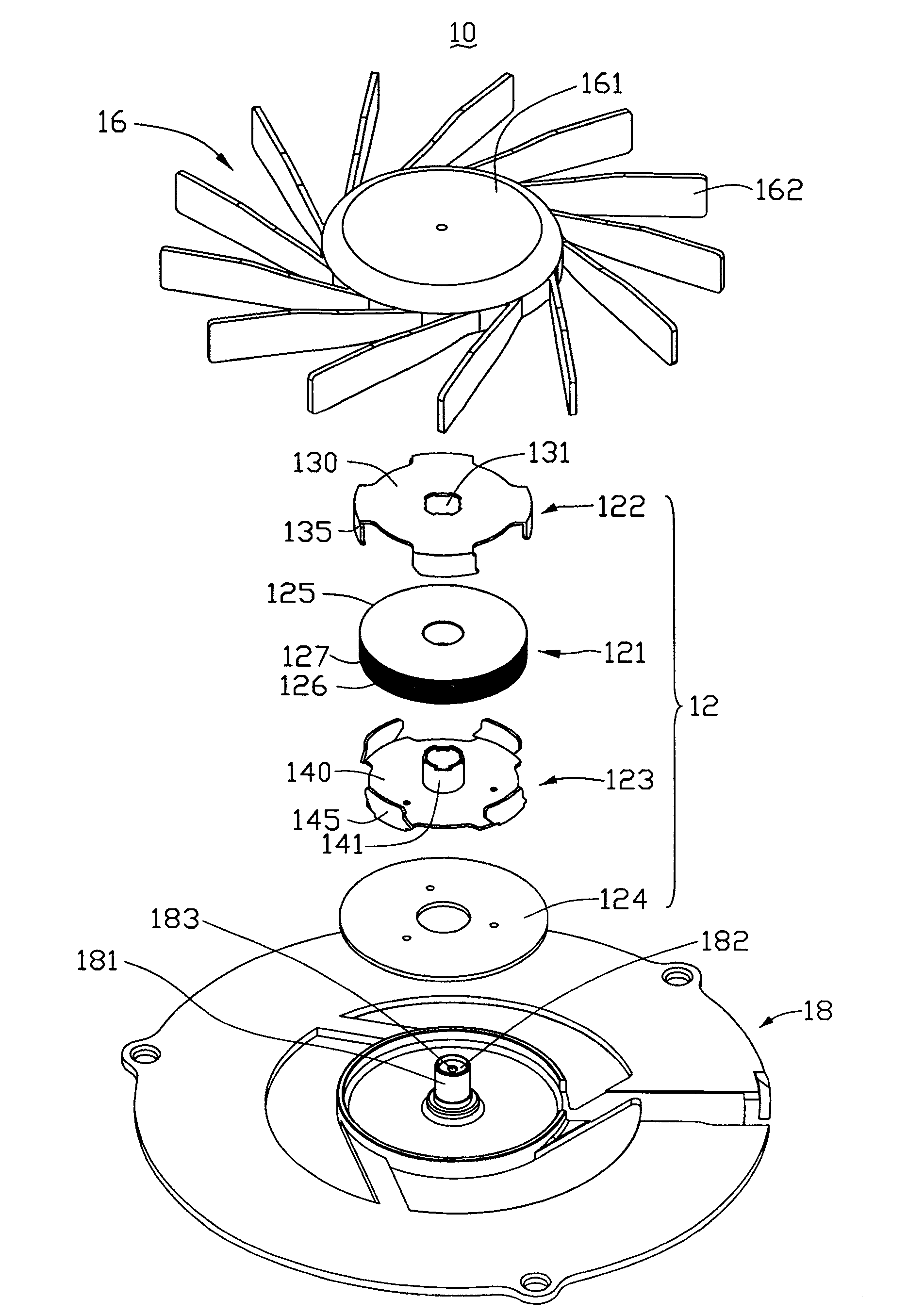

[0017] figure 1 Shown is an exploded perspective view of a preferred embodiment of the motor 10 of the present invention. The motor 10 includes a stator group 12 and a rotor 16. The stator group 12 is disposed on a housing 18, and the rotor 16 is covered by the rotor 16. on the stator group 12.

[0018] The rotor 16 includes a hub 161 and a plurality of blades 162 surrounding the hub 161. Permanent magnets (not shown) are arranged in the hub 161. The center of the hub 161 extends downward to form a rotating shaft (not shown). A central column 181 is arranged in the middle of the seat 18 and is penetrated through the stator group 12 . A bearing 182 is arranged in the central column 181 , and a shaft hole 183 is arranged in the central axis of the bearing 182 for the shaft of the rotor 16 to pass through to support the rotation of the rotor 16 . .

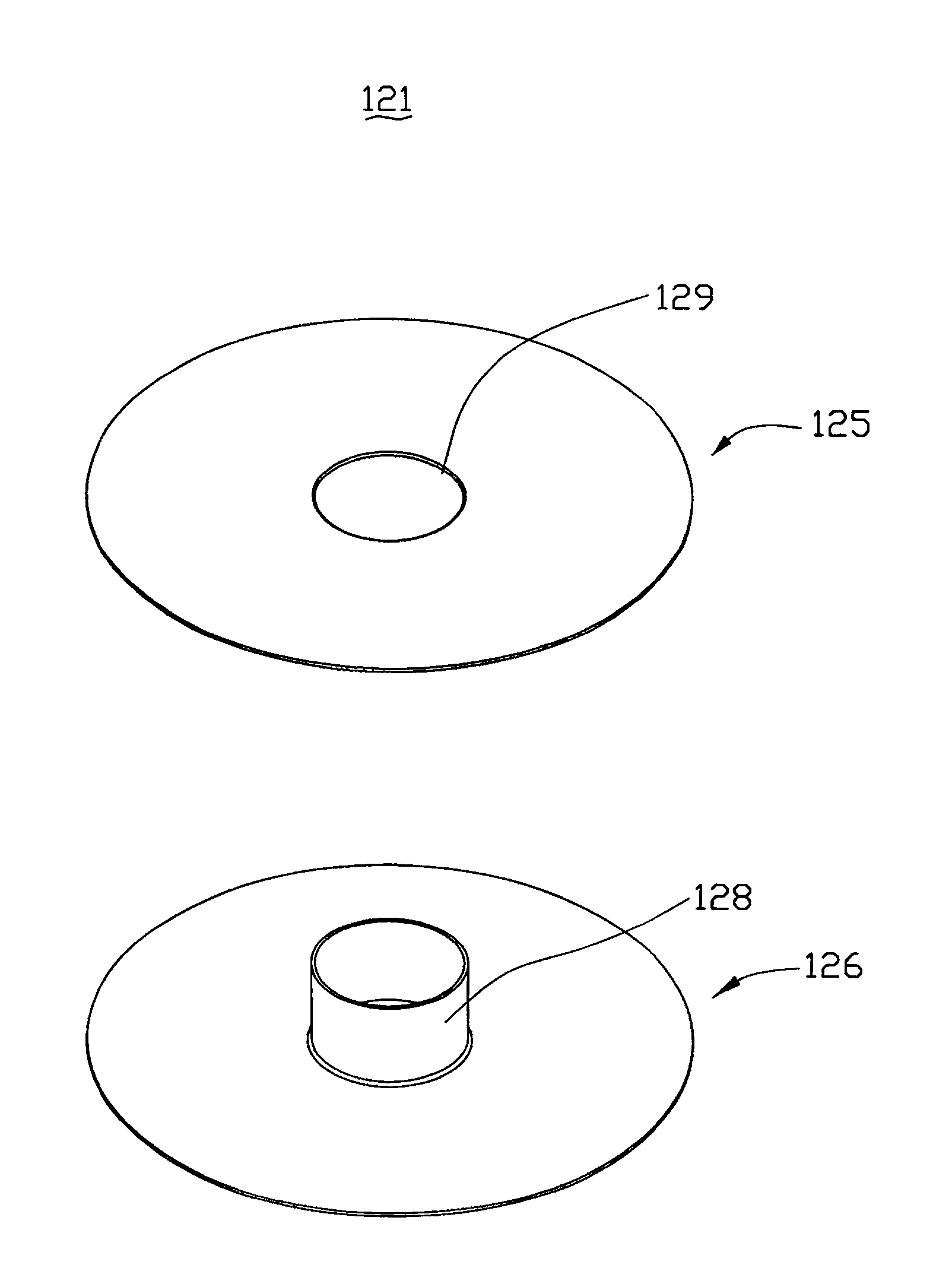

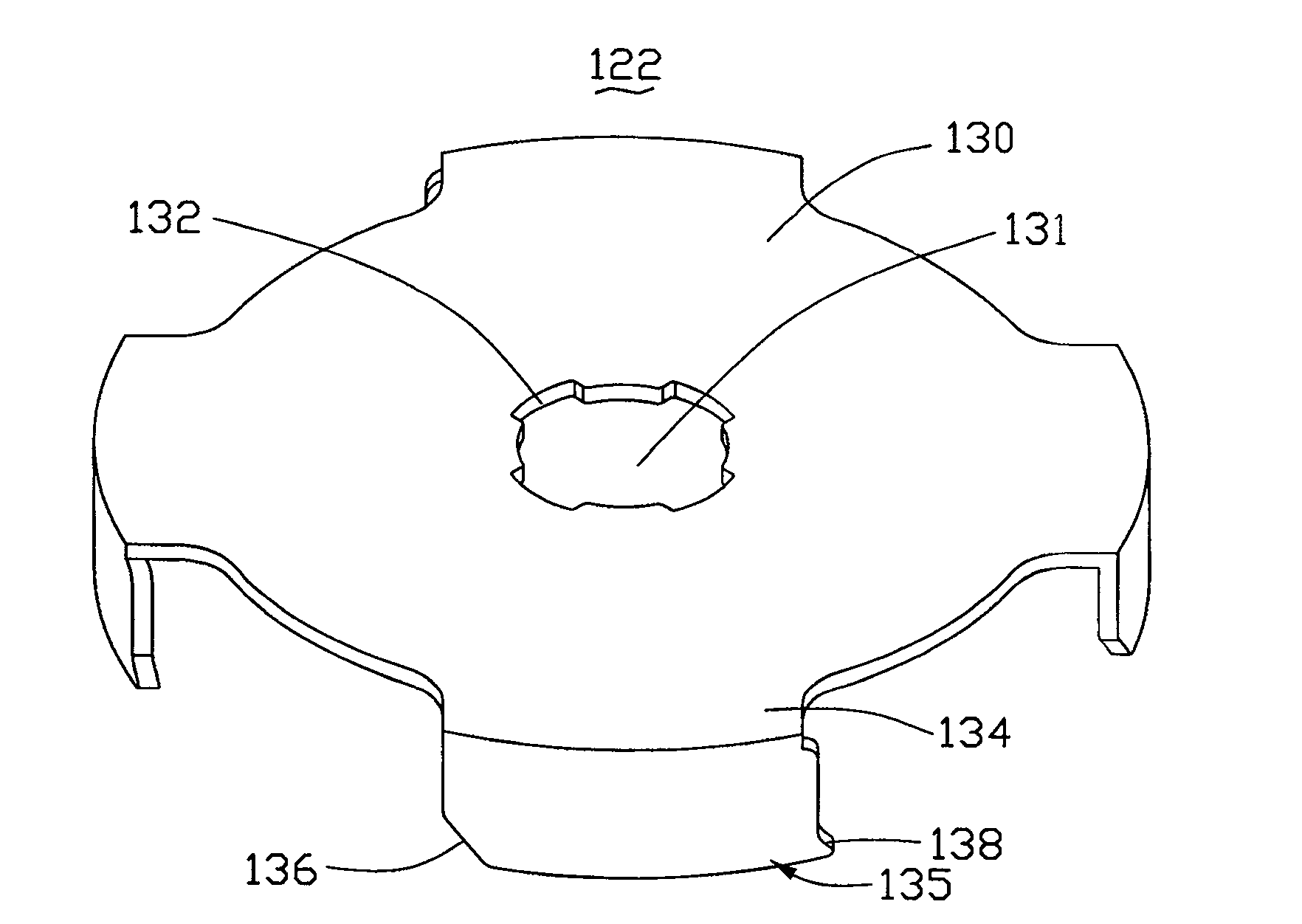

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com