Control device for starting LCD power supply

A technology for starting a power supply and a control device, which is applied in the field of control and can solve problems such as the inability to clarify and ensure the correct sequence of the logic power supply and the backlight power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

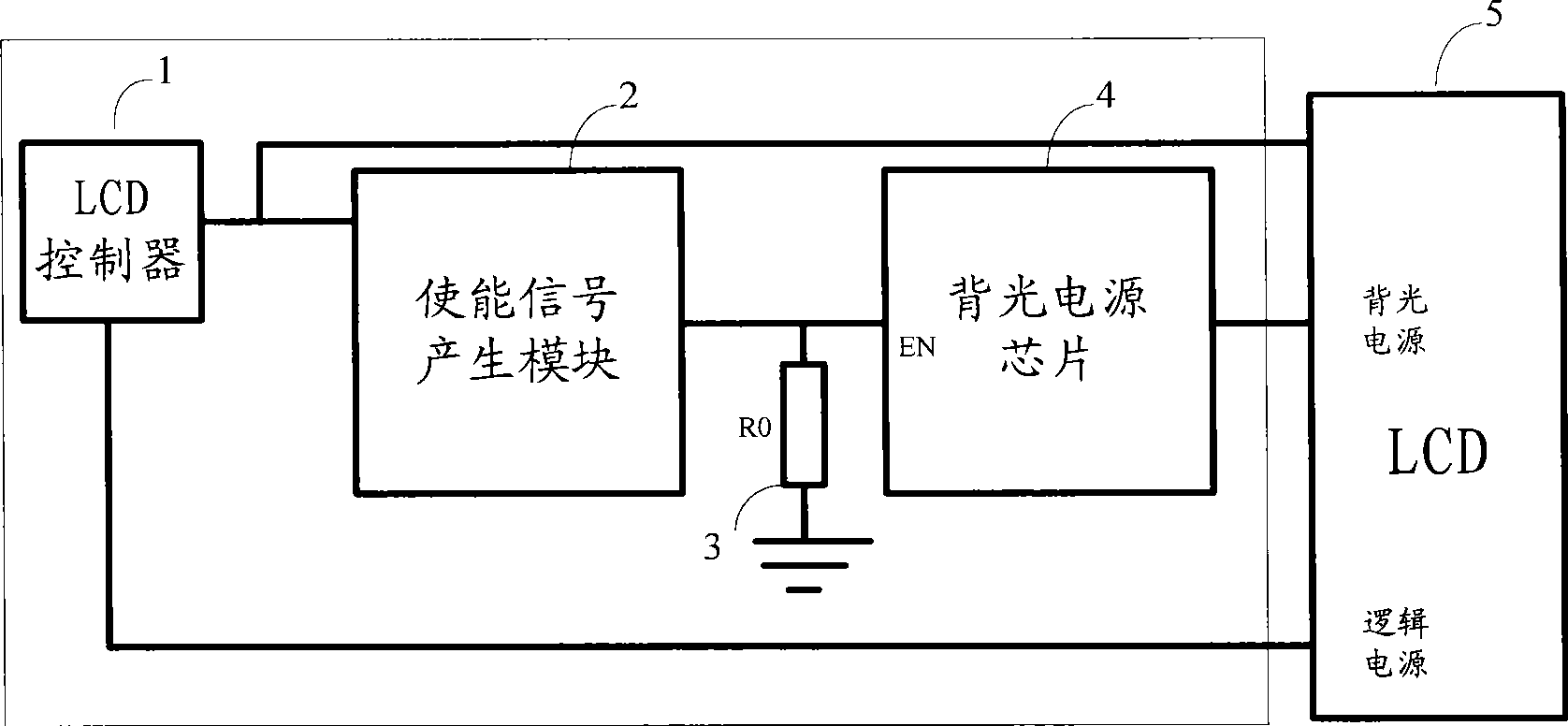

[0061] The difference between the second embodiment and the first embodiment is that the control device further includes: a CPU controller 7 .

[0062] The power interface of the LCD controller 1 is connected to the logic power supply of the LCD 5 . The output port of the LCD controller 1 is connected to the first input end of the enable signal generating module 2 and the control signal input end of the LCD 5 . One output port of the CPU controller 7 is connected to the second input port of the enable signal generating module 2 . The output terminal of the enable signal generating module 2 is connected to the enable pin of the backlight power supply chip 4 . The output terminal of the backlight power supply chip 4 is connected to the backlight power supply of the LCD 5 . The pull-down resistor R03 is connected between the enable pin of the backlight power supply chip 4 and the ground.

[0063] When the LCD 5 is turned on and powered on, the LCD controller 1 is started by th...

Embodiment 3

[0073] The difference between the third embodiment and the first embodiment is that the output terminal of the enabling signal generating module 2 is connected to the third input terminal of the enabling signal generating module 2 to form a feedback loop.

[0074] When the LCD 5 is turned on and powered on, the LCD controller 1 is started by the logic power supply. The LCD controller 1 outputs a control signal to the enable signal generating module 2 .

[0075] The enable signal generating module 2 sends the enable signal to the backlight power supply chip 4 after receiving the control signal output by the LCD controller 1 and the enable signal fed back by itself.

[0076] The backlight power supply chip 4 receives the enable signal, is enabled, and lights up the LCD 5 .

[0077] The pull-down resistor R0 3 is used to ensure that the backlight power supply chip 4 is disabled at the moment when the LCD 5 is powered on.

[0078] The control device according to the third embodi...

Embodiment 5

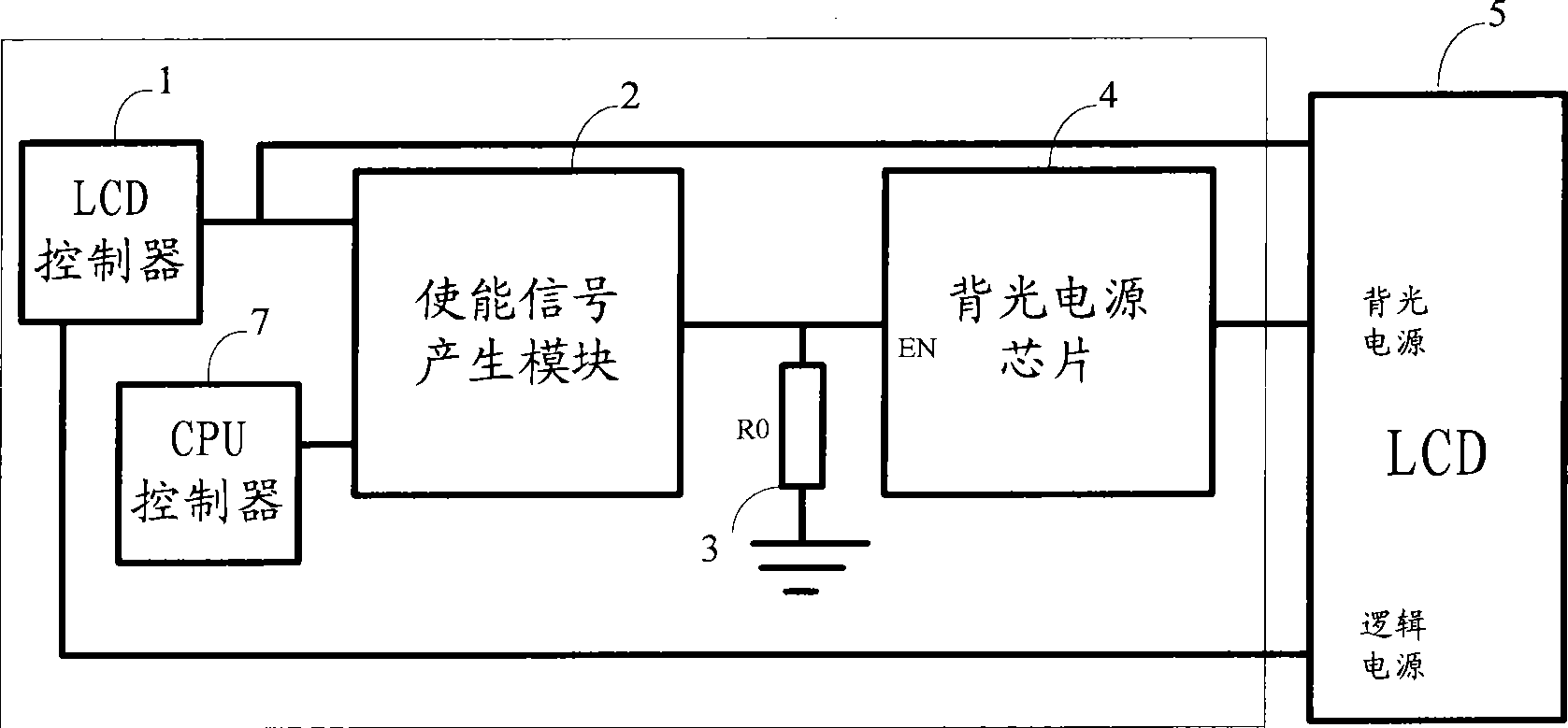

[0110] The difference between the fifth embodiment and the fourth embodiment is that the control device further includes a CPU controller 7 .

[0111] The power supply interface of the LCD controller 1 is connected to the controller power supply 6 . The output terminal of the LCD controller 1 is connected to the first input terminal of the enable signal generating module 2 and the control signal input terminal of the LCD 5 . The logic power supply of the LCD 5 is connected to the second input terminal of the enable signal generating module 2 . One output port of the CPU controller 7 is connected to the third input end of the enable signal generating module 2 . The output terminal of the enable signal generating module 2 is connected to the enable pin of the backlight power supply chip 4 . The output terminal of the backlight power supply chip 4 is connected to the backlight power supply of the LCD 5 . The pull-down resistor R03 is connected between the enable pin of the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com