A start method for DC frequency conversion compressor

A DC frequency conversion and compressor technology, which is applied to the starter of a single DC motor, the speed reducer of an AC motor, and the motor generator/starter, etc. It can solve the problems of high motor current, large current, and high DC power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

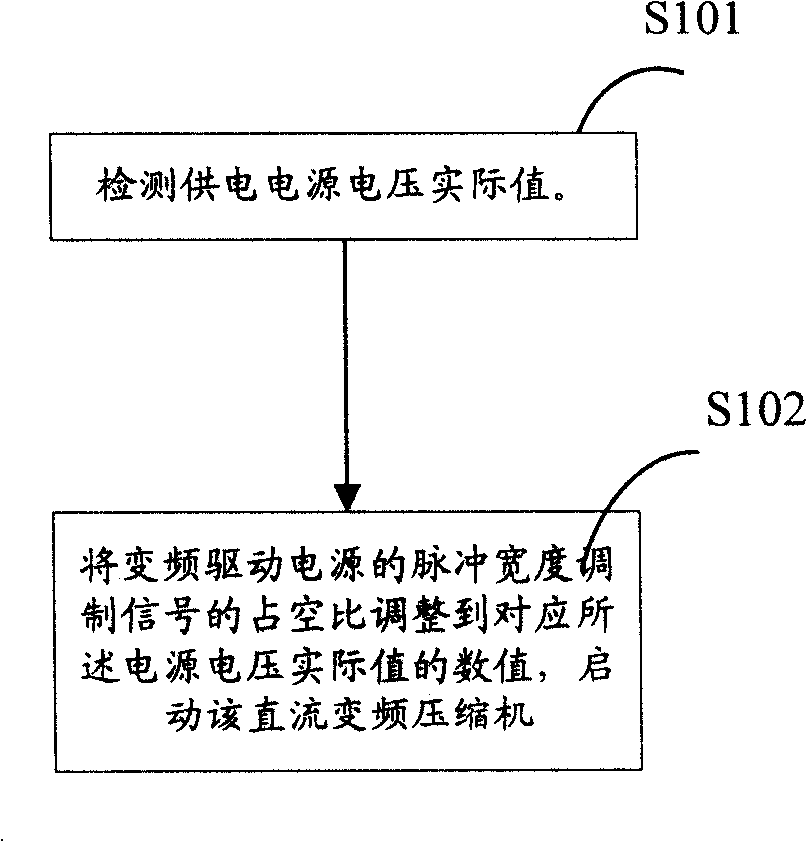

[0051] Please see figure 1 , which shows the starting method of the DC inverter compressor provided by the first embodiment of the present invention.

[0052] Step S101, detecting the actual value of the power supply voltage.

[0053] The power supply voltage is the voltage provided to the variable frequency driving power supply for driving the DC variable frequency compressor. Taking a general household air conditioner or refrigerator as an example, the power supply voltage is the AC mains, and its phase voltage is theoretically 220V. However, due to the load circuit The voltage may fluctuate between 150V-255V due to the impact and quality of power supply.

[0054] Step S202, according to the actual value of the power supply voltage obtained by detection, adjust the duty cycle of the pulse width modulation signal of the variable frequency drive power supply to a value corresponding to the actual value of the power supply voltage, and start the DC variable frequency compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com