Stamping machine with elastic supporting work piece support and method for supporting work piece in the stamping machine

A stamping machine and elastic parts technology, applied in metal processing, perforating tools, manufacturing tools, etc., can solve problems such as scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

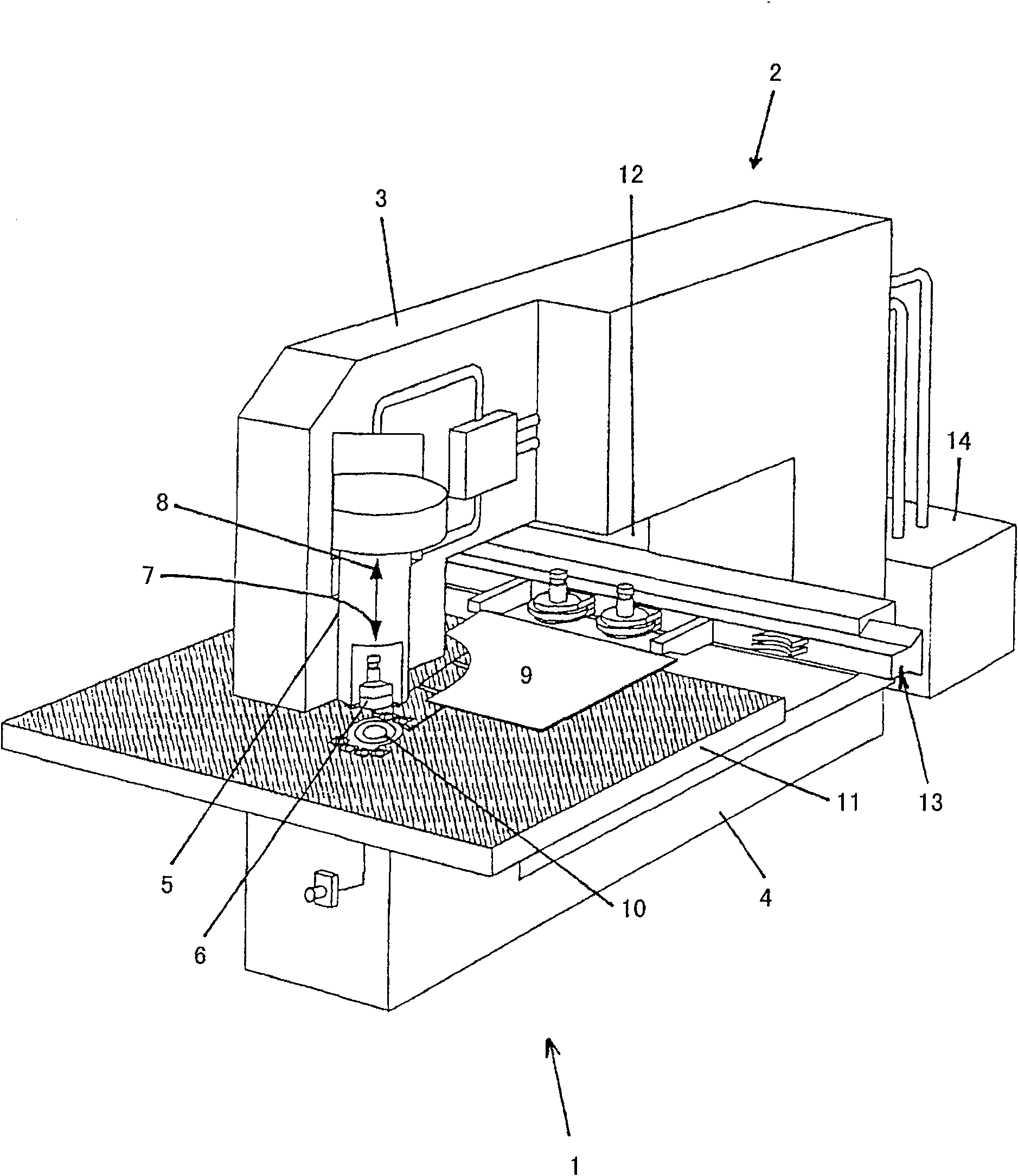

[0027] according to figure 1 , The punching machine 1 has a C-shaped frame 2 with an upper frame part 3 and a lower frame part 4 .

[0028] Mounted on the free end of the upper frame part 3 is a drive 5 for a stamping tool in the form of a punch or for a tool bearing 6 provided with the punch. Via this drive 5 , the tool bearing 6 is linearly movable together with the punch in the machining stroke direction 7 or in the return stroke direction 8 . During the working stroke for machining the workpiece and during the return stroke following the working stroke, a movement is carried out by the tool bearing 6 or the punch in the machining stroke direction 7 or the retraction direction 8 .

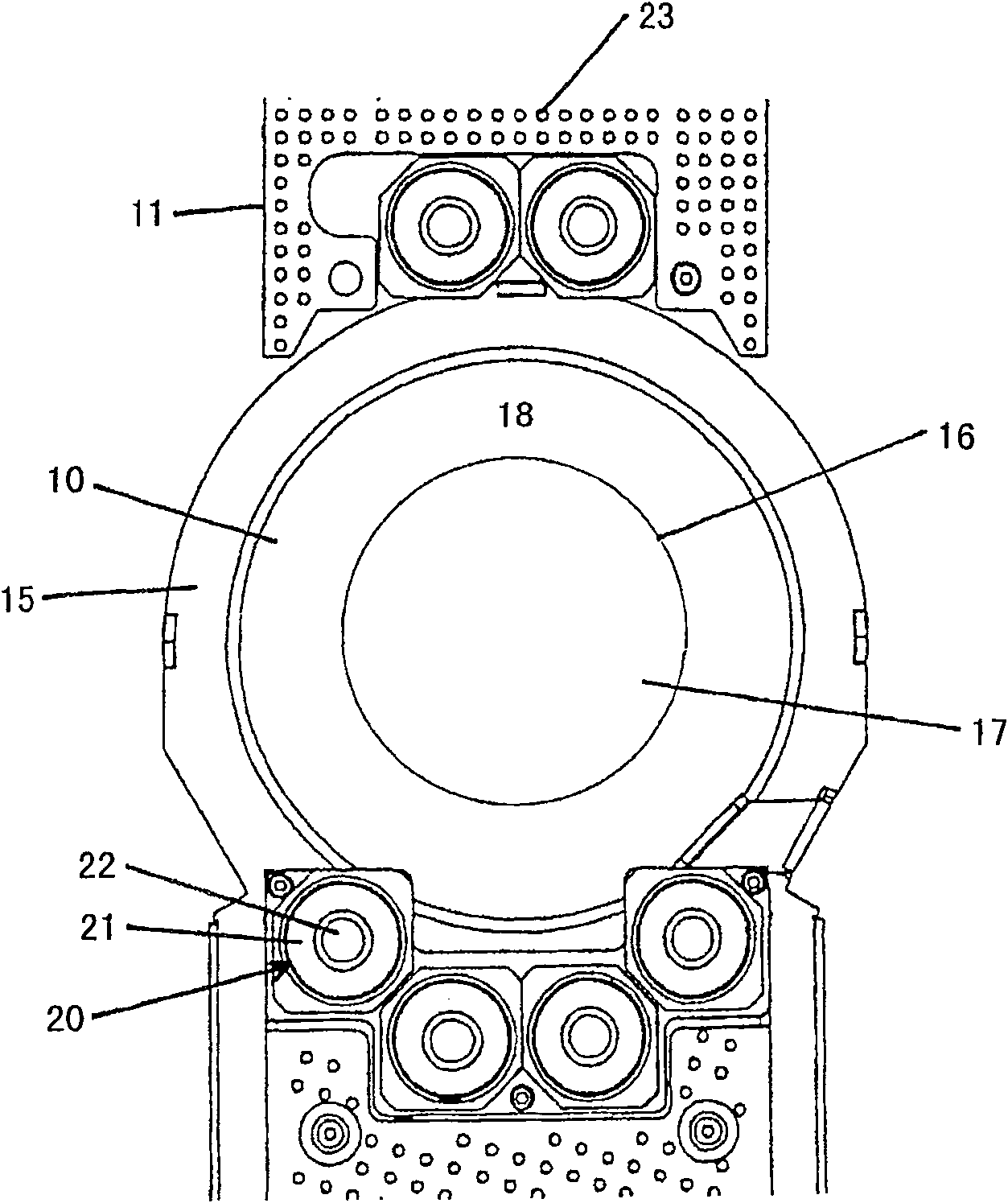

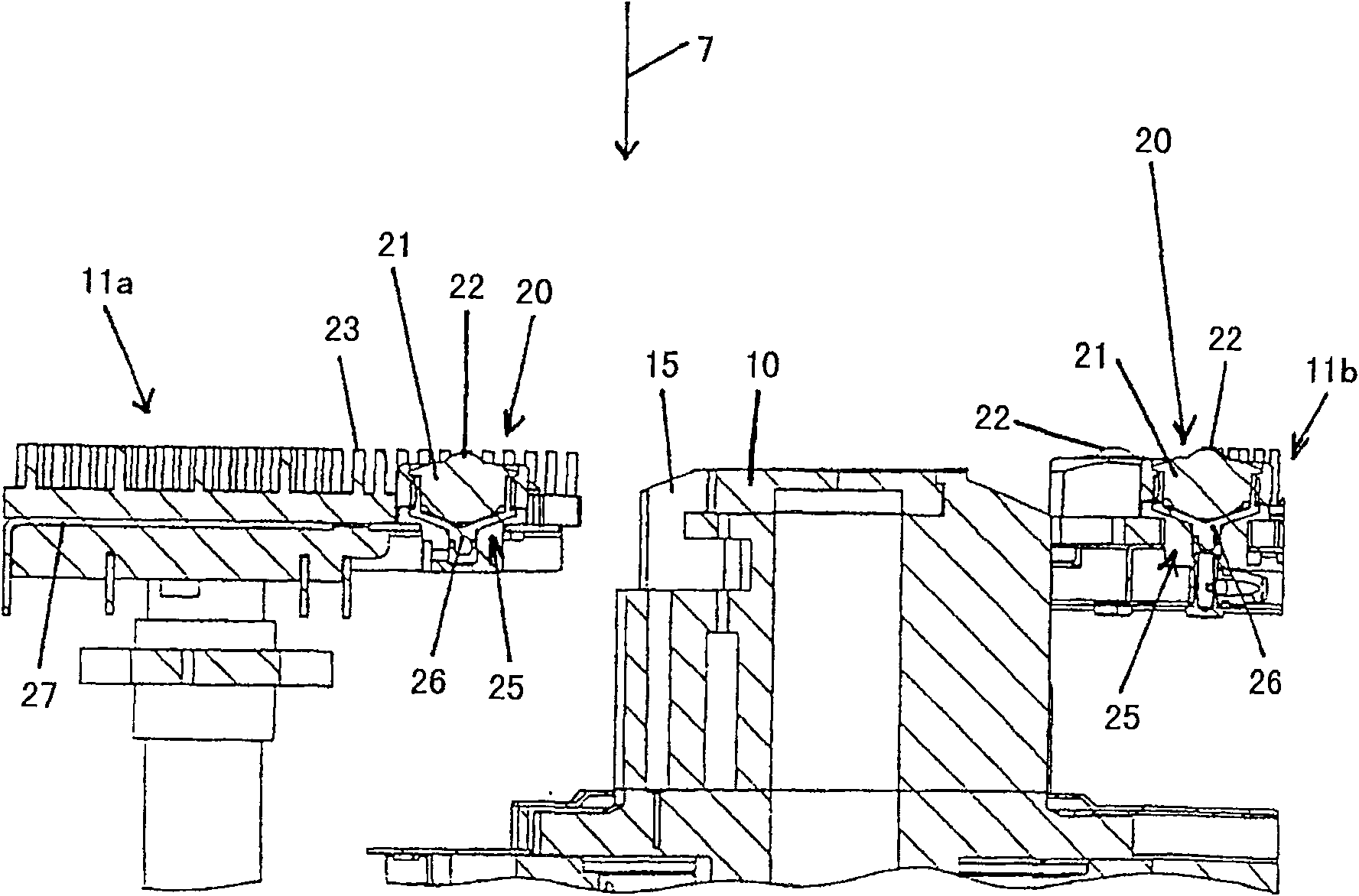

[0029] During the machining of the workpiece, in the illustrated embodiment, during the stamping of the sheet metal 9 , the die interacts with a lower stamping tool in the form of a stamping die 10 . The stamping die is integrated into a workpiece table 11 , which is itself supported on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com