Injection system

A technology of injection system and injector, which is applied in the direction of charging system, fuel injection pump, low-pressure fuel injection, etc., can solve the problems of large installation space, high manufacturing cost, installation cost and maintenance cost, occupation of injection system, etc., to achieve compact The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

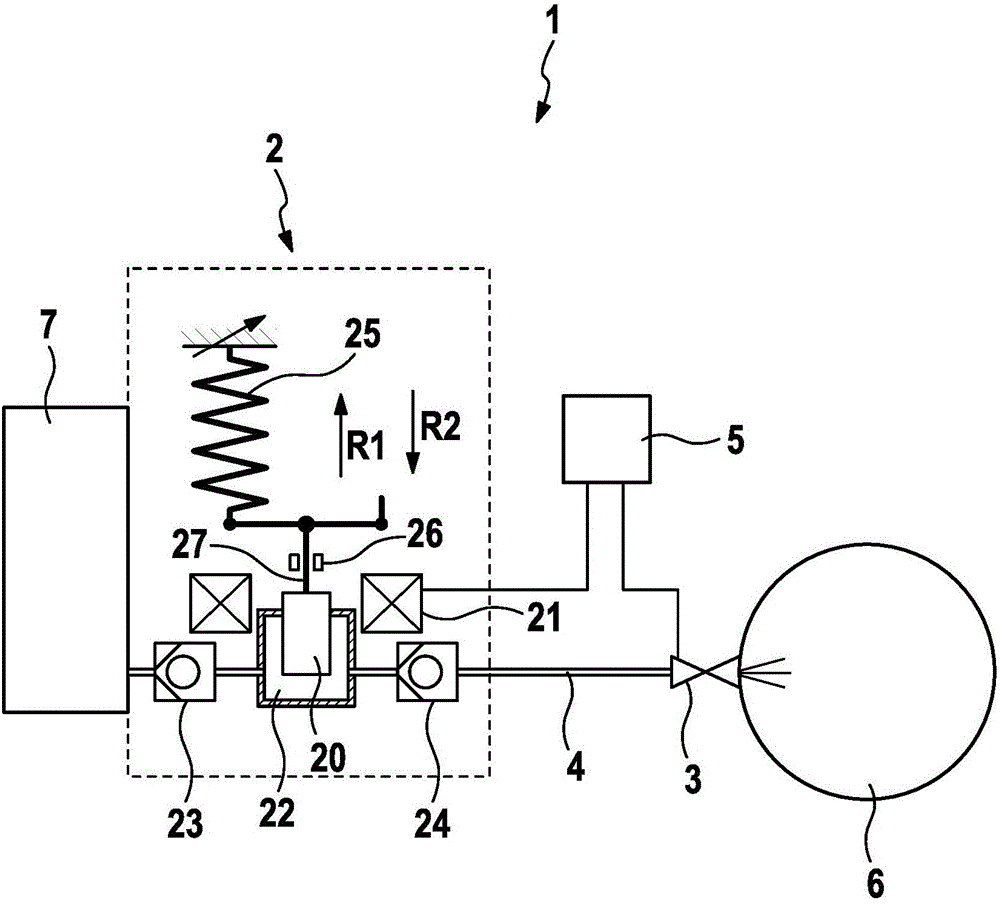

[0018] as from figure 1 As seen in , the injection system 1 according to the invention comprises a fuel pump 2, an injector 3 and a pressure line 4 which is arranged between the fuel pump 2 and the injector 3 and which connects the fuel pump 2 to the Injector 3 is connected. In this case, the pressure line 4 is designed as an elastic hose.

[0019] The fuel pump 2 has a piston 20 , an actuator 21 for actuating the piston 20 , a delivery chamber 22 into which the piston 20 can protrude, an inlet valve 23 , an outlet valve 24 and an operating spring 25 . The working spring 25 is an adjustable coil spring, ie the spring force of the working spring 25 can be adjusted. In addition, the inlet valve 23 and the outlet valve 24 are configured as ball valves. The actuator 21 includes an electromagnetic coil. Other types of actuators, such as piezoelectric actuators or magnetostrictive actuators, are likewise conceivable.

[0020] Furthermore, in this exemplary embodiment the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com