Assembled wheel guiding system arm

A technology of boom and wheel suspension, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of increasing cost pressure and construction period pressure, troublesome molds, and prone to failure, etc., and achieve cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

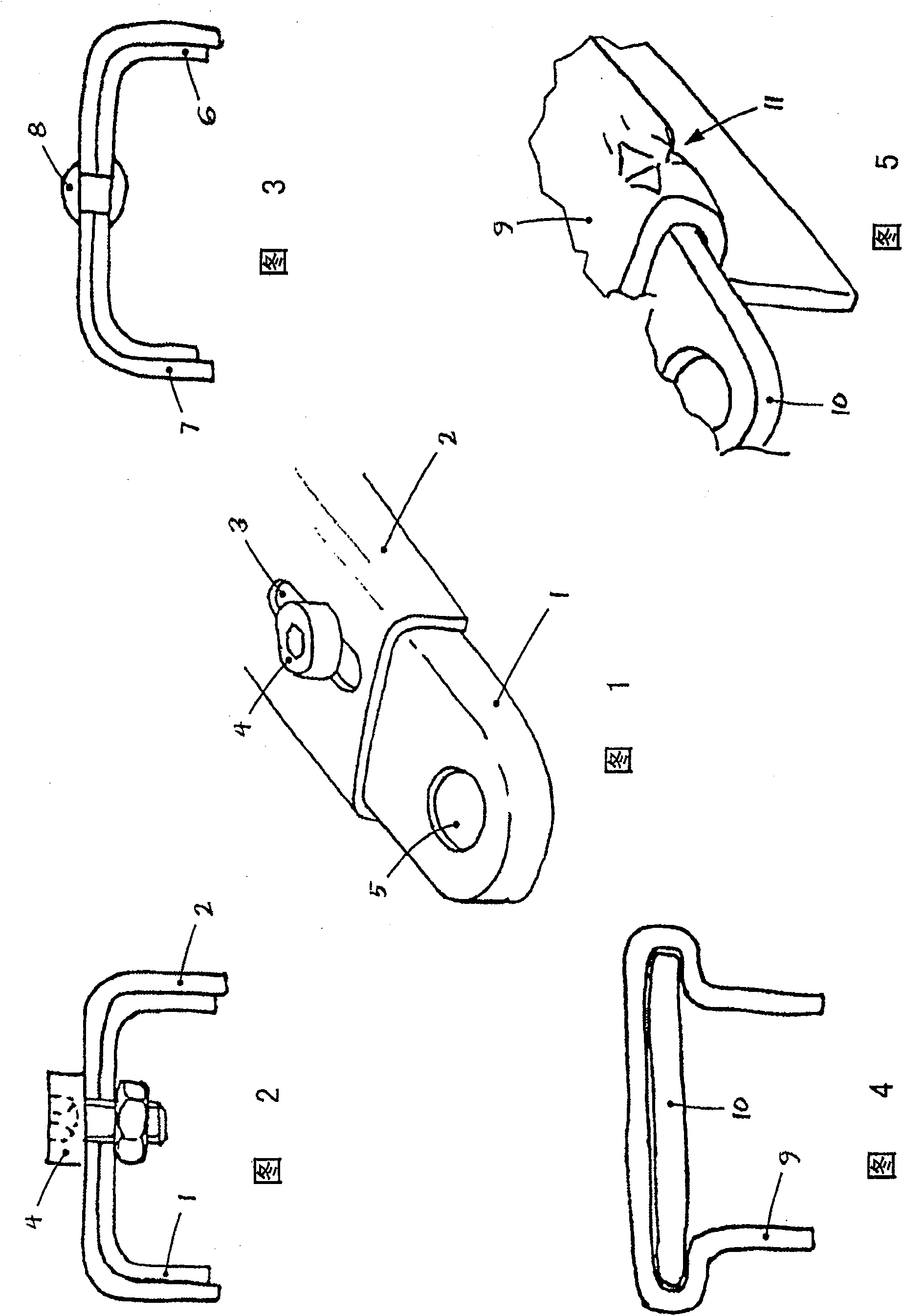

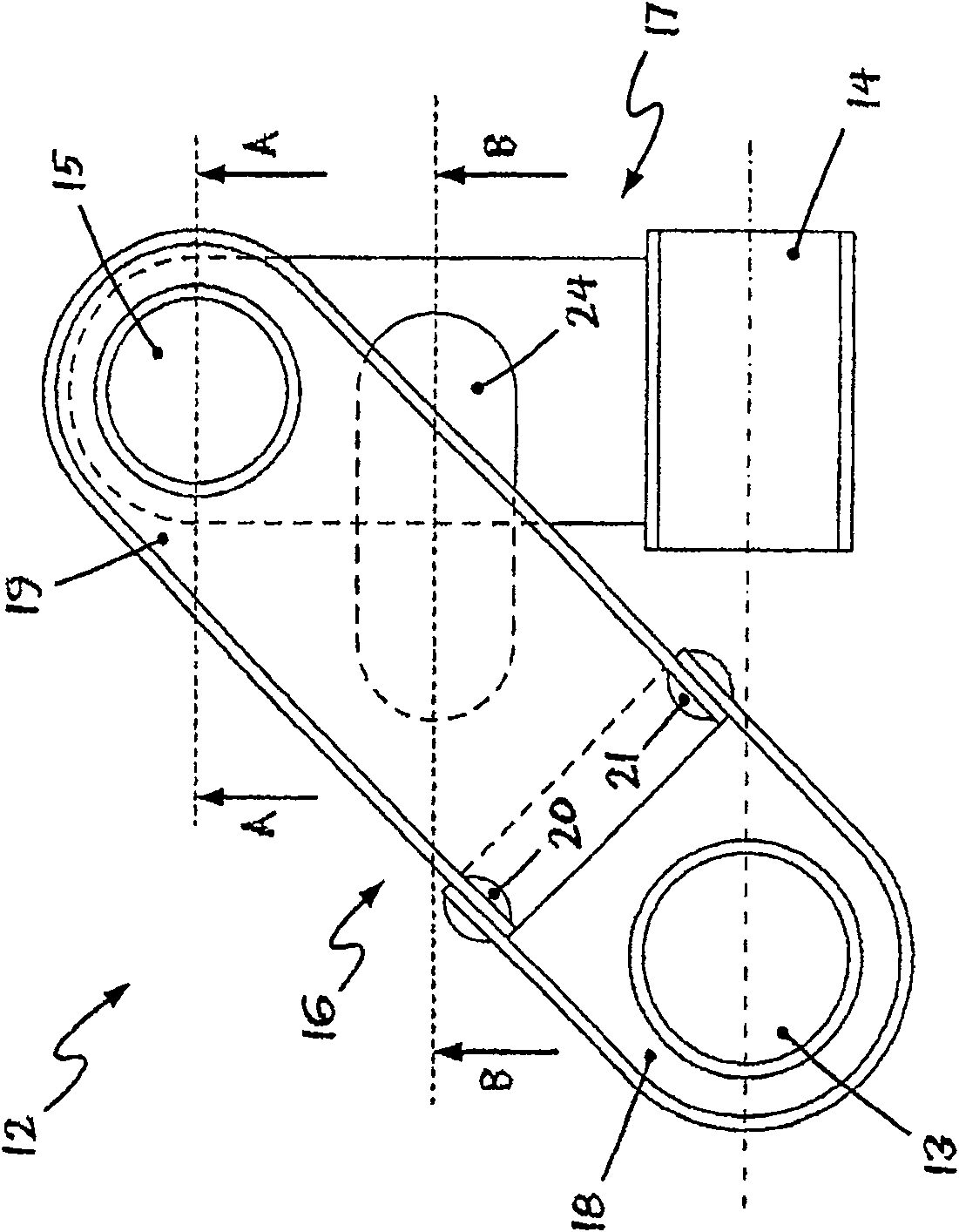

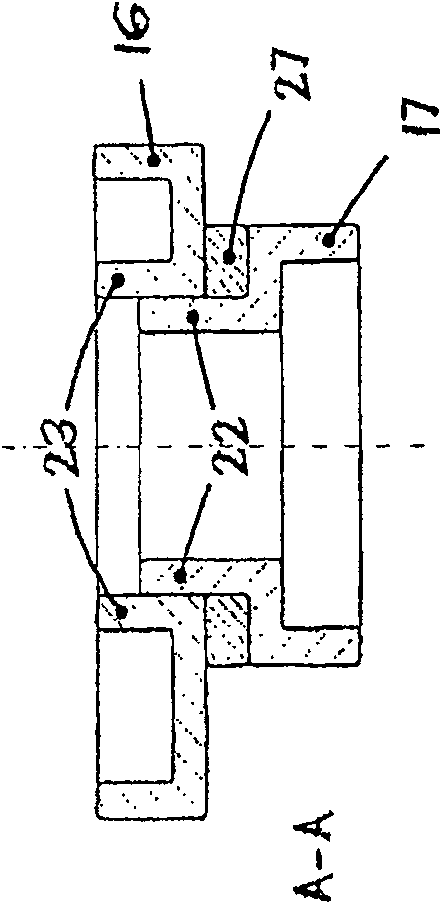

[0035] figure 1 Two profiled parts 1 , 2 or strut arrangements 1 , 2 of a jib having features according to the invention are shown schematically. Wherein, the two profiled parts 1, 2 are connected to each other by means of elongated holes 3 and bolts 4, such as through figure 1 The moldings 1, 2 are described in figure 2 As shown in the cross-sectional diagram in . The profiled parts 1 , 2 thus form part of a jib of a wheel guide system, shown here only in part, for example a strut jib or also a strut structure of a triangular transverse arm.

[0036] It can be seen that the profiled parts 1 , 2 of the arm support according to the invention differ from the prior art in the form of the profiled parts 1 , 2 which can be produced relatively easily by bending or deep drawing. The hole 5 in the profiled part 1 is used to connect the arm, for example by means of a ball joint or an elastomer joint, to a body structure or to a wheel guide structure, such as a steering knuckle, a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com