Connector structure with lock mechanism

A locking mechanism and connector technology, which is applied to igniters with fuel, couplings, mechanical equipment, etc., can solve the problems of hindering miniaturization, troublesome and defective removal of supply equipment, etc., and achieve the effect of reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

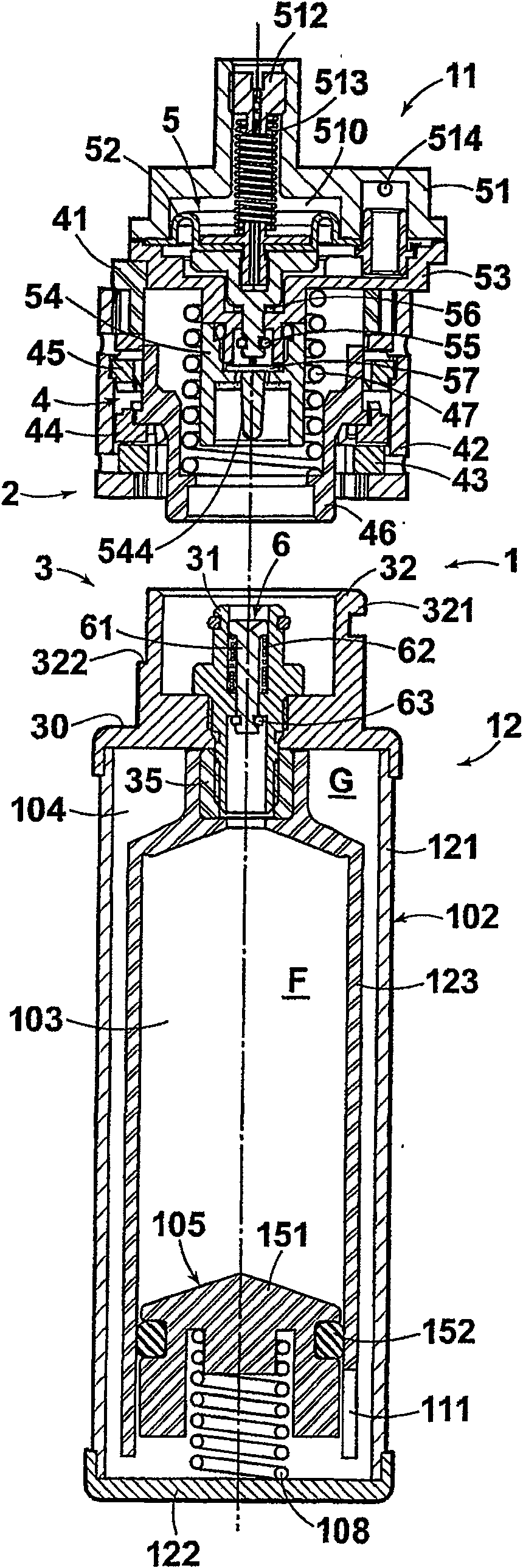

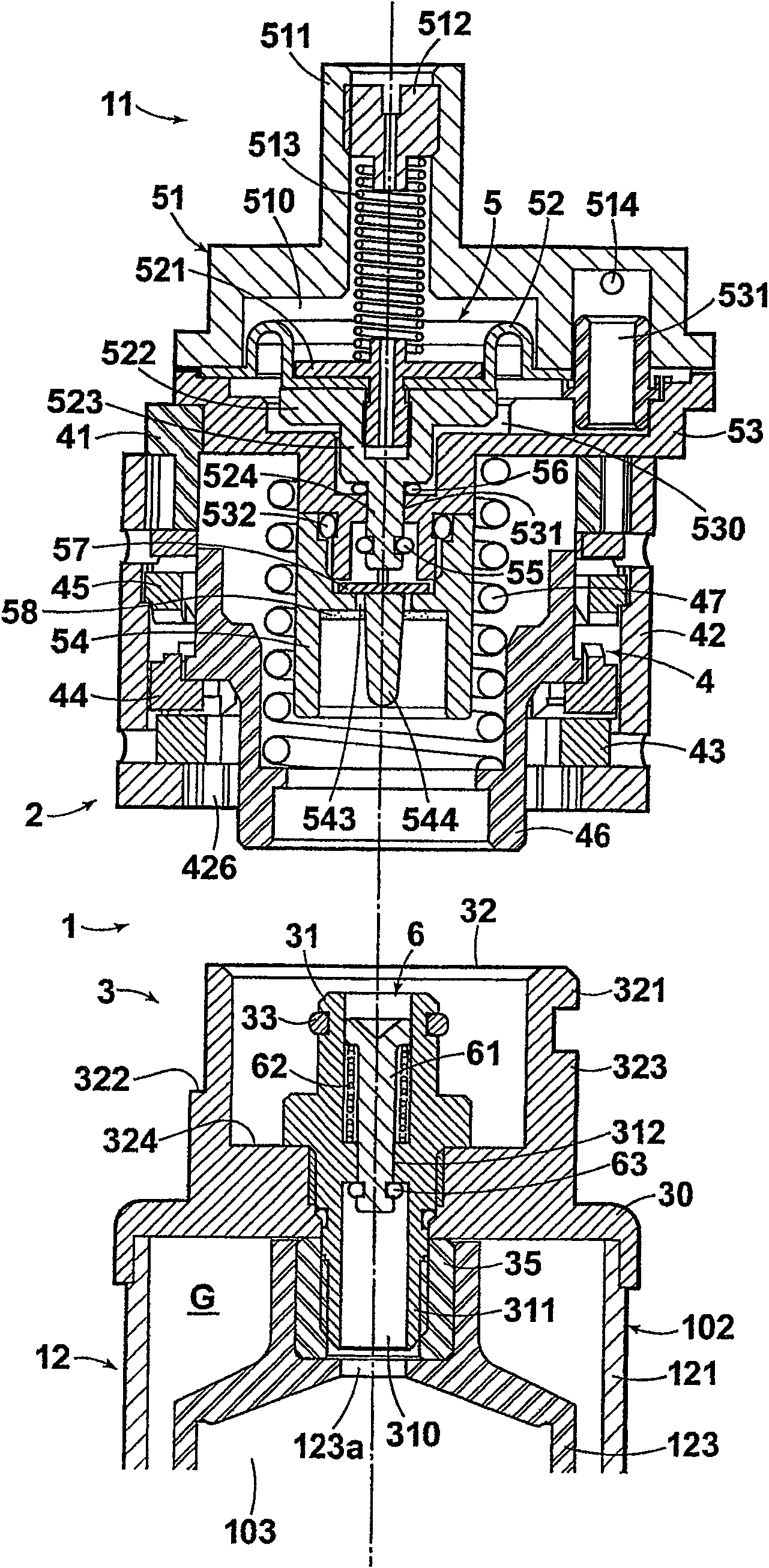

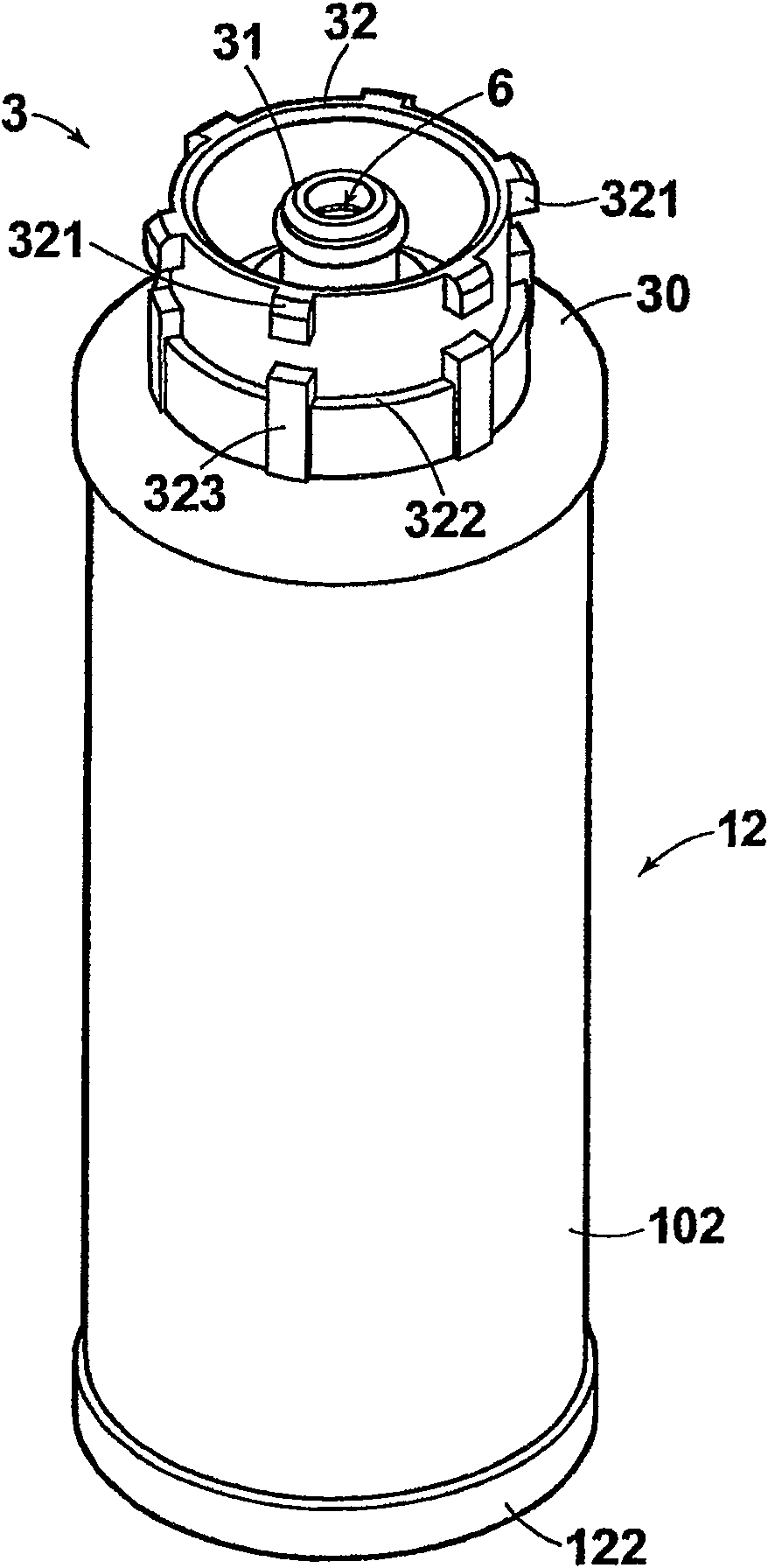

[0041] figure 1 and figure 2 The connector structure 1 of the embodiment is composed of a receiving connection part 2 provided on a receiving device 11 such as a fuel cell that uses fluid such as liquid fuel, and a supply device such as a fuel cartridge that is provided in a pressurized state to supply the fluid. The supply connection part 3 on 12 constitutes, when the fluid F is supplied from the supply device 12 to the receiving device 11, the receiving connection part 2 and the supply connection part 3 are connected to a locked state by the fixing mechanism 4 (pawl mechanism). The receiving connection part 2 has the main part of the fastening mechanism 4, and also has the pressure regulating mechanism 5 (adjusting mechanism) for regulating the supply fluid to a constant secondary pressure. On the other hand, the supply connection part 3 has a valve mechanism 6 having a lever valve 61 biased in the valve-closing direction by a spring 62 in the plug-shaped supply connection...

no. 2 example

[0095] Figure 14 It is an exploded perspective view of the main parts of the fastening mechanism (pawl mechanism) of the second embodiment, Figure 15 Indicated by removing part of the bracket Figure 14 The diagram of the action state of the fastening mechanism.

[0096] The difference between this embodiment and the first embodiment is that: the surface of the first ring 43 that contacts the second ring 44 has unevenness 434 . Others are the same as those in the first embodiment, and are marked with the same symbols, and descriptions are omitted.

[0097] In this embodiment, with the upward movement of the supply connection part 3, when the guide protrusion 442 of the second ring 44 disengages from the second guide groove 424, as Figure 15 As shown, the second ring 44 obtains a rotational force by contacting the slope of the lower surface of the third ring 45, and also obtains a rotational force toward the rotational direction d by contacting the unevenness 434 of the f...

no. 3 example

[0101] Figure 16 It is an exploded perspective view of the main parts of the fixing mechanism (pawl mechanism) of the third embodiment, Figure 17 and Figure 18 Is only represented by the main parts Figure 16 The cross-sectional view of the action state of the fastening mechanism.

[0102] In this embodiment, the second ring 44 is always biased by the release spring 47 to produce a rhythmic click sound of the ratchet.

[0103] Specifically, by arranging spring brackets 48 of different shapes, the biasing force of the release spring 47 does not directly act on the supply connection portion 3, but acts on the separation direction through the second ring 44, and other parts and the second ring 44 are separated. One embodiment is the same and marked with the same symbol, and the description is omitted.

[0104] The spring bracket 48 of this embodiment includes: a cylindrical upper tube portion 481; a lower tube portion 482 having a smaller outer diameter than the upper tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com