Process for preparing a lyophilised material

A dry, controlled technology, applied in the field of process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

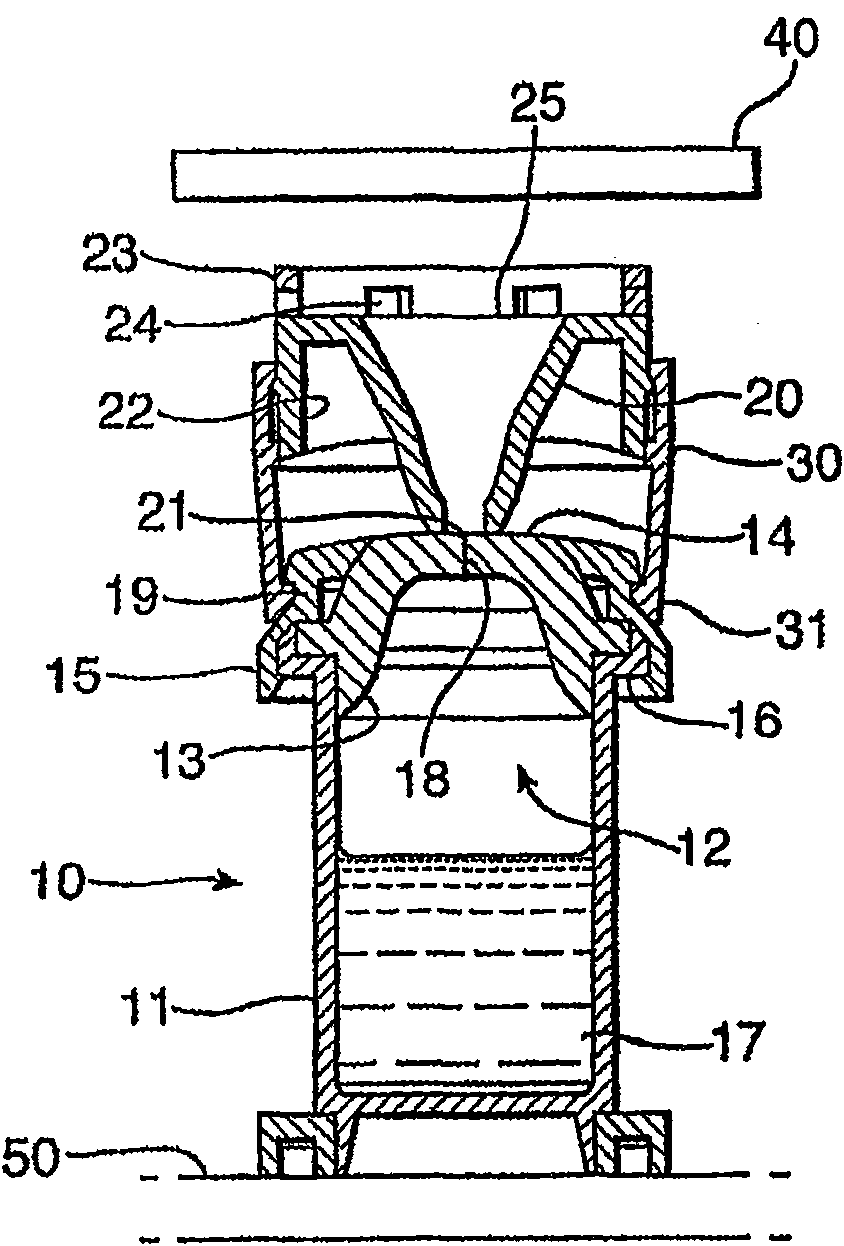

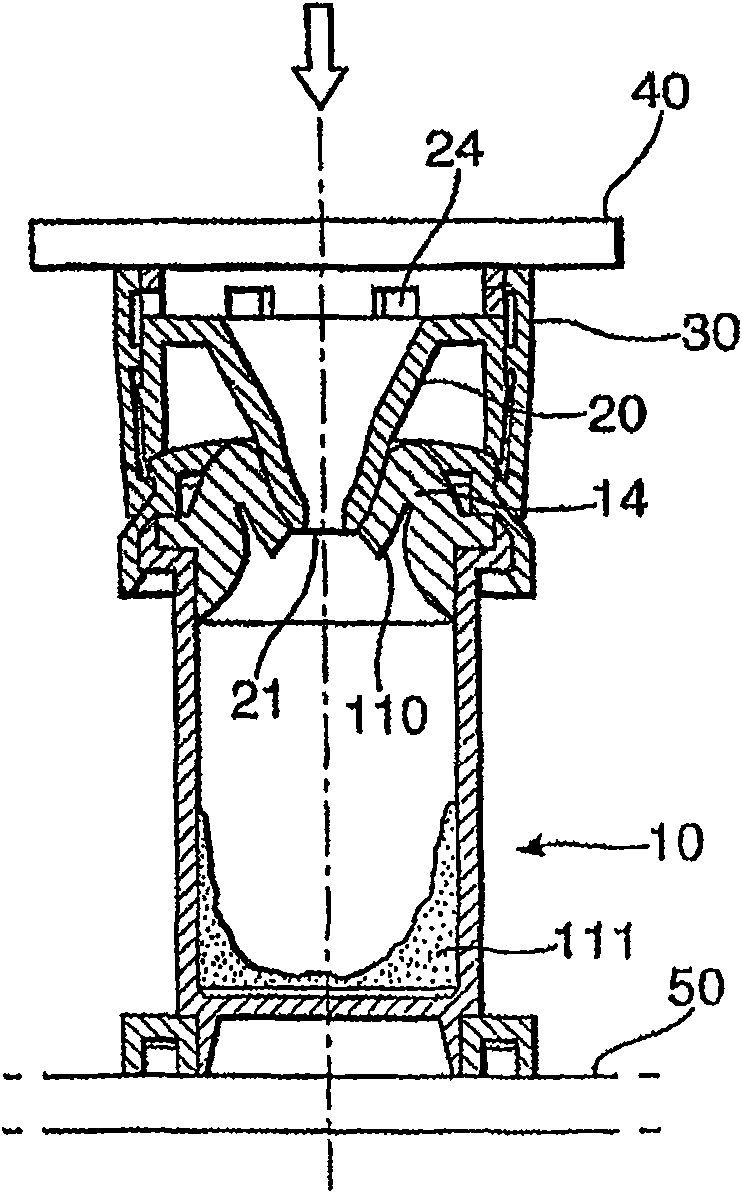

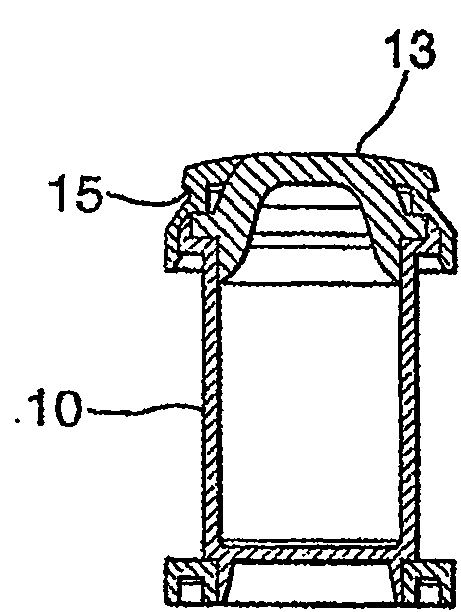

[0088] refer to figure 1 with figure 2 , shows a pharmaceutical vial 10 in longitudinal section, which is of the type disclosed in WO-A-04 / 018317. The vial 10 comprises a generally cylindrical body 11 made of transparent plastic material with an upper mouth 12 closed by an elastomeric plug closure 13 having an upper domed region 14 . The closure 13 is held in place on the vial body 11 by clamping parts 15 of plastics material which snap fit onto the flange 16 of the vial body 10 . The combination of vial body 10 and stopper closure 13 comprises an envelope as referred to in this application.

[0089] The vial 10 contains an aqueous solution 17 of vaccine material which is freeze-dried after subsequent freezing into a solid plug by lowering its temperature. The closure 13 has a piercing hole 18 extending completely through it. The solution 17 is released by sterilizing the interior of the vial 10 with radiation, passing a hollow perfusion needle (not shown) through the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com