Photon crystal composite encoding microsphere and preparation method

A technology of photonic crystal microspheres and photonic crystals, which is applied in the direction of material analysis, measuring devices, instruments, etc. by optical means, can solve the problems of indistinguishable emission peaks of emitted light, complicated detection equipment, complicated preparation, etc., and achieves adjustable color. , the effect of wide application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

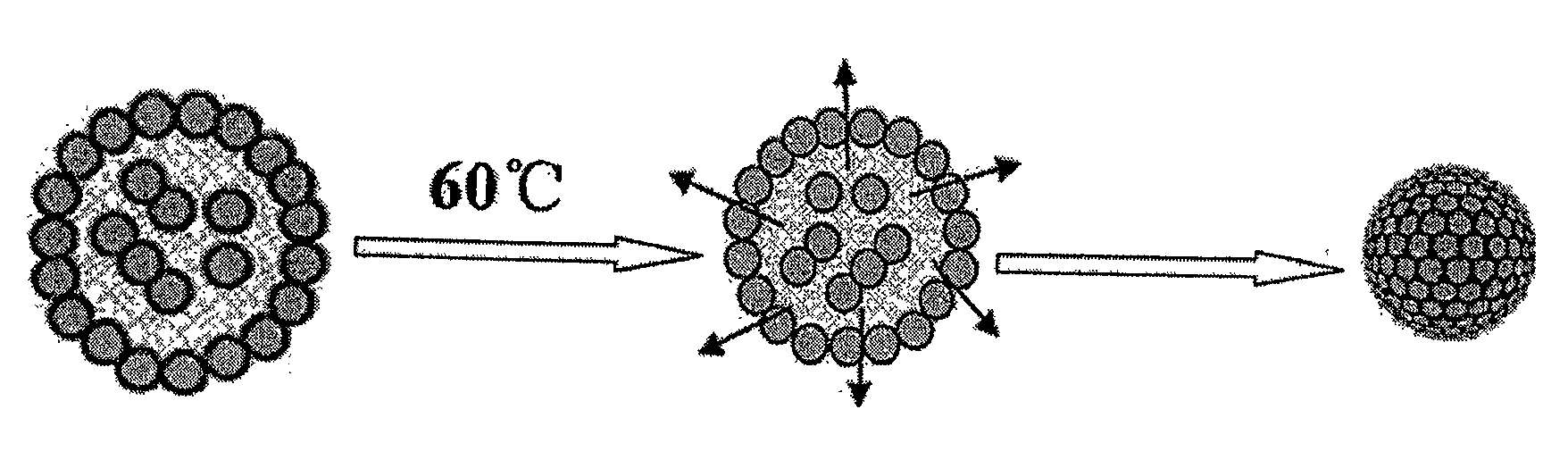

[0025] The preparation method includes the following steps:

[0026] Select photonic crystal microspheres with different codes and perform surface treatment on them to obtain negatively charged photonic crystal coded microspheres;

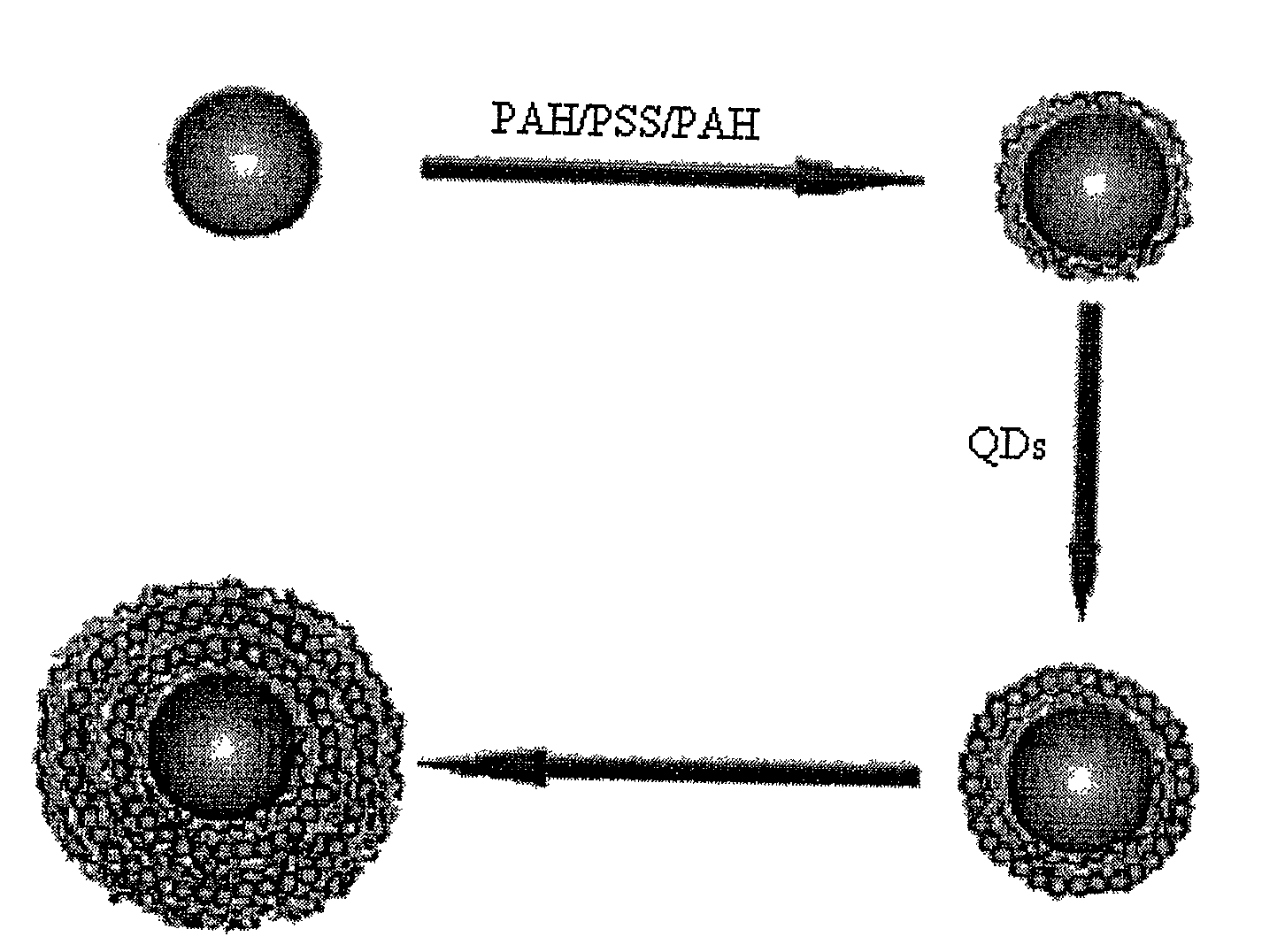

[0027] Using the layer-by-layer adsorption method, the positive polyelectrolyte is first adsorbed on the surface of the photonic crystal microsphere, and then the negative polyelectrolyte is adsorbed, and then after the positive polyelectrolyte is adsorbed, the quantum dots with different characteristic emission peaks are adsorbed on the outer surface of the microsphere;

[0028] To absorb quantum dots of different layers or different sizes, the layers are separated by three layers of polyelectrolyte;

[0029] The quantum dots in the outermost layer continue to adsorb four layers of polyelectrolyte to facilitate detection.

[0030] At the same time, use quantum dots of the same kind but different sizes to label the object to be detected, and the concen...

Embodiment 1

[0031] Example one. Preparation of water-soluble CdTe labeled polystyrene microspheres

[0032] 1 Select the polystyrene microspheres coded at 600nm and 540nm respectively. Since the synthesized polystyrene particles have carboxyl groups, the surface of the prepared microspheres is also negatively charged.

[0033] 2 Soak the prepared microspheres in a 0.5mol / L NaCl solution of 1mg / mL PAH, stand for 20 minutes to absorb, rinse with ultrapure water three times to wash off excess PAH. Then the microspheres were immersed in 0.5mol / L NaCl solution of 1mg / mLPSS, and the same was allowed to stand for adsorption and centrifugal washing. After adsorbing another layer of PAH, soak the microspheres in CdTe modified with thioglycolic acid 540 (Emission spectrum at 540nm) in an aqueous solution, stand and absorb for 60 minutes, then centrifuge and wash.

[0034] 3 Repeat the above steps. After adsorbing three layers of polyelectrolyte, then adsorb the second layer of CdTe 540 . By analogy, thre...

Embodiment 2

[0036] 实施例二。 Example two. Preparation of water-soluble CdTe labeled silica microspheres

[0037] 1 Select 400nm, 460nm and 540nm coded silica microspheres respectively, and immerse them in 70% (V / V 0 ) Sulfuric acid and 30% hydrogen peroxide solution overnight, so that the surface of the prepared microspheres is negatively charged.

[0038] 2 Soak the prepared microspheres in a 0.5mol / L NaCl solution of 1mg / mL PAH, stand for 20 minutes to absorb, rinse with ultrapure water three times to wash off excess PAH. Then the microspheres were immersed in 0.5mol / L NaCl solution of 1mg / mLPSS, and the same was allowed to stand for adsorption and centrifugal washing. After adsorbing another layer of PAH, soak the microspheres in CdTe modified with thioglycolic acid 540 (Emission spectrum at 540nm) in an aqueous solution, stand and absorb for 60 minutes and then centrifuge and wash.

[0039] 3 Repeat the above steps. After adsorbing three layers of polyelectrolyte, then adsorb the second layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com