Yarn feeder

A kind of equipment and yarn feeding technology, which is applied in the direction of thin material processing, textile and paper making, loom, etc., can solve the problems that the joint area is easy to be damaged, and the free end part is easy to vibrate violently, so as to improve the running performance, increase the firmness, modify simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

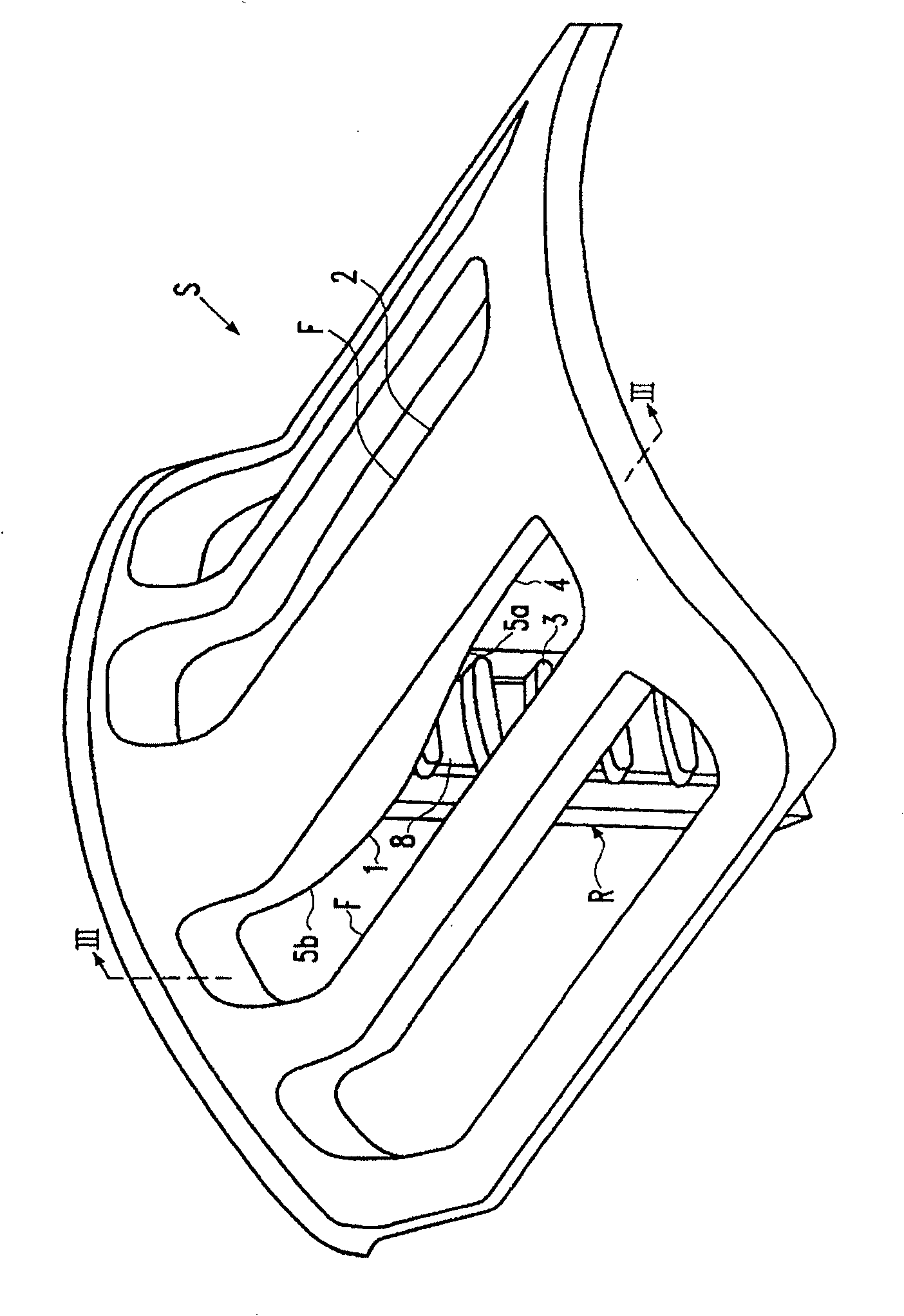

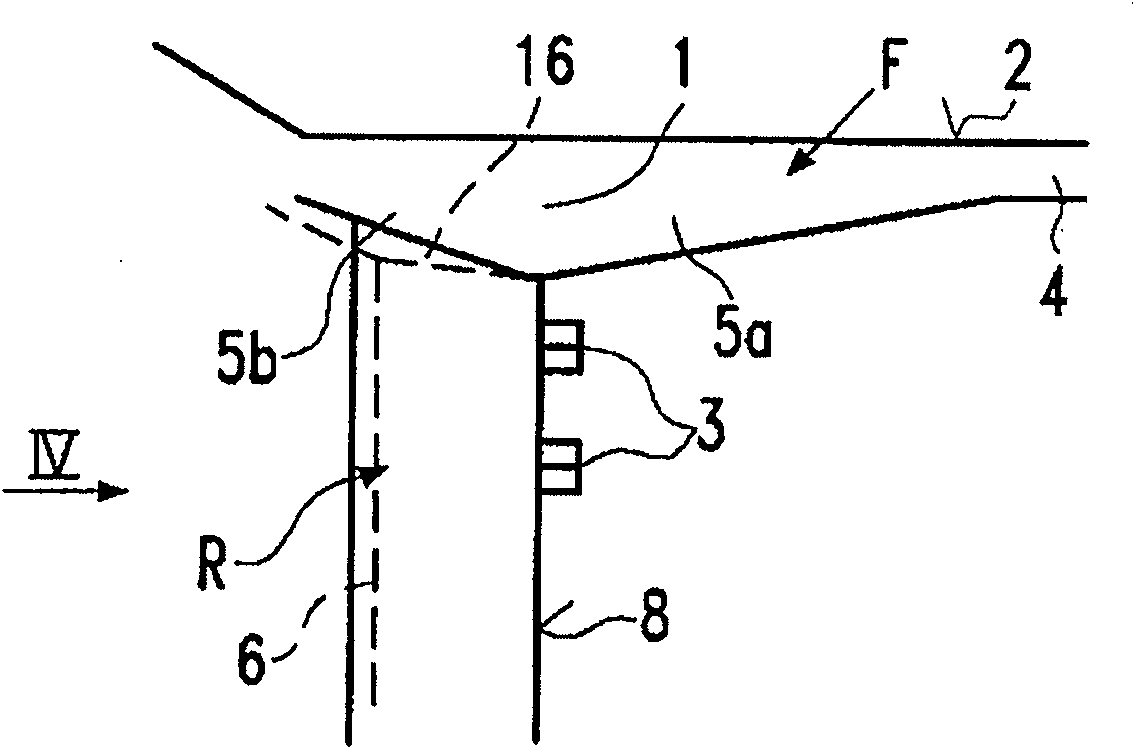

[0023] Figure 6-9 The conventional arcuate portion S'shown is designated with a dot primed reference numeral. Of the embodiments of the present invention Figure 1-5a The same reference numerals without dot primes are used in.

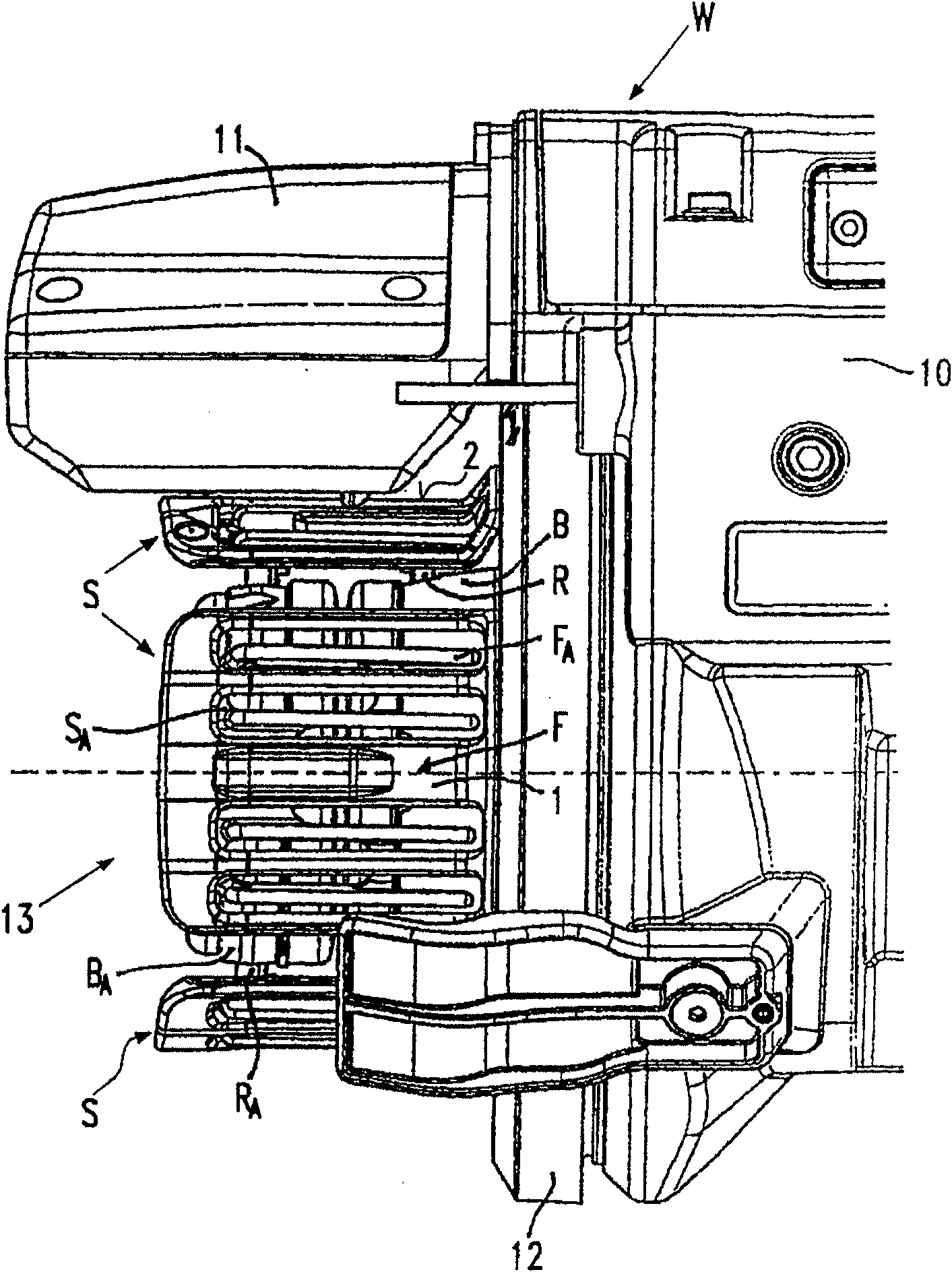

[0024] Yarn feeding equipment W, such as figure 1 As shown in part, it is a so-called measuring yarn feeding device that is conventionally used in nozzle looms. The yarn feeding device W has a housing 10 and the housing 10 fixedly supports a storage body 13. The brake housing 11 fixed to the housing 10 is structurally combined with the outer circumference of the storage body 13 in a total number that is substantially the same and regularly distributed in the circumferential direction of the storage body 13, such as one of the four fixed arches S The circumferential position. Each fixed arcuate portion S includes a number of substantially parallel finger structures F and a first rod R. Each finger structure constitutes the yarn storage surface 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com