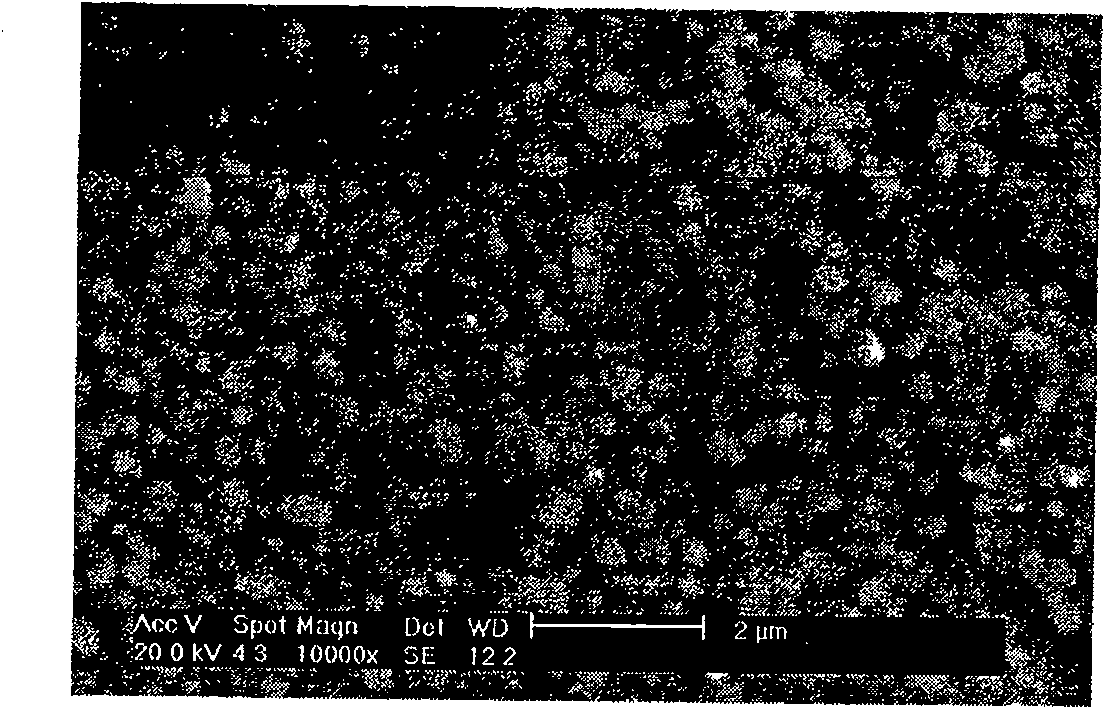

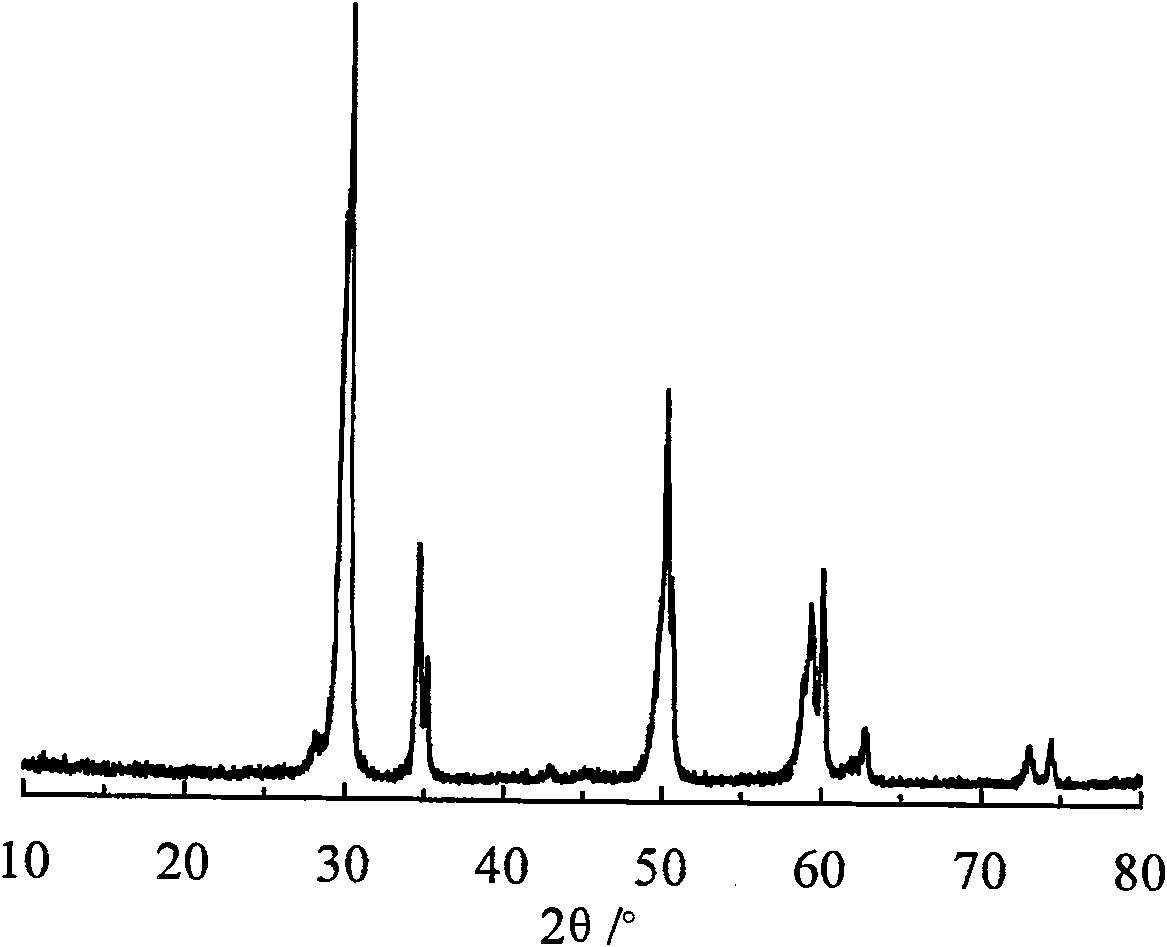

Low-temperature sintering producing method of cubic polycrystal zirconia ceramics with yttrium oxide as stabilizing agent

A zirconia ceramic and low-temperature sintering technology, which is applied in the field of preparation of tetragonal polycrystalline zirconia ceramics, can solve the problems of uneven distribution and affect the stability of material properties, and achieves low sintering temperature, inhibition of grain growth, good medium and high temperature performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] MgO-Al 2 o 3 -SiO 2 Preparation of composite precursor sol:

[0031] According to MgO:Al 2 o 3 : SiO 2 Accurately weigh 102.6 grams of MgCl with a molar ratio of 0.5:3:1.5 2 ·6H 2 O, 1428.6 g AlCl 3 ·6H 2 O and 321.45 g Si(OC 2 h 5 ) 4 . 321.45 g of Si(OC 2 h 5 ) 4 Hydrolyze for 24 hours, then add deionized water to 2 liters as the base solution; 102.6 grams of MgCl 2 ·6H 2 O and 1428.6 g AlCl 3 ·6H 2 O was dissolved in 1 liter and 2 liters of deionized water respectively to obtain a solution containing magnesium ions and aluminum ions, and then the solution containing magnesium ions and aluminum ions was dropped into Si(OC 2 h 5 ) 4 In the hydrolysis solution, keep the pH value of the solution at 9-10.5 by dripping ammonia water simultaneously, constantly stir Si(OC 2 h 5 ) 4 hydrolysis solution. Continue to stir for half an hour after the titration to obtain a white sol. After the sol was filtered by suction, it was washed with deionized wate...

Embodiment 2

[0035] MgO-Al 2 o 3 -SiO 2 Preparation of composite precursor sol:

[0036] According to MgO:Al 2 o 3 : SiO 2 The molar ratio was 0.8:2.3:1 and 205.1 grams of Mg(NO 3 ) 2 ·6H 2 O, 1725 g Al(NO 3 ) 3 9H 2 O and 208.33 g Si(OC 2 h 5 ) 4 . 208.33 g of Si(OC 2 h 5 ) 4 Hydrolyze for 24 hours, then add deionized water to 2 liters, as the base liquid; 205.1 grams of Mg(NO 3 ) 2 ·6H 2 O and 1725 g Al(NO 3 ) 3 9H 2 O was dissolved in 1 liter and 2 liters of deionized water respectively to obtain a solution containing magnesium ions and aluminum ions, and then the solution containing magnesium ions and aluminum ions was dropped into Si(OC 2 h 5 ) 4 In the hydrolysis solution, keep the pH value of the solution at 9-10.5 by dripping ammonia water simultaneously, constantly stir Si(OC 2 h 5 ) 4 hydrolysis solution. Continue to stir for half an hour after the titration to obtain a white sol. After the sol was filtered by suction, it was washed with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com