Method for testing oxygen transmission rate of package bag

A technology of oxygen permeability and packaging bag, which is applied in the field of testing the oxygen permeability of packaging bags, can solve the problems of increasing the economic burden of enterprises and high equipment prices, and achieves the effect of objective and reliable results, low difficulty and saving mechanical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

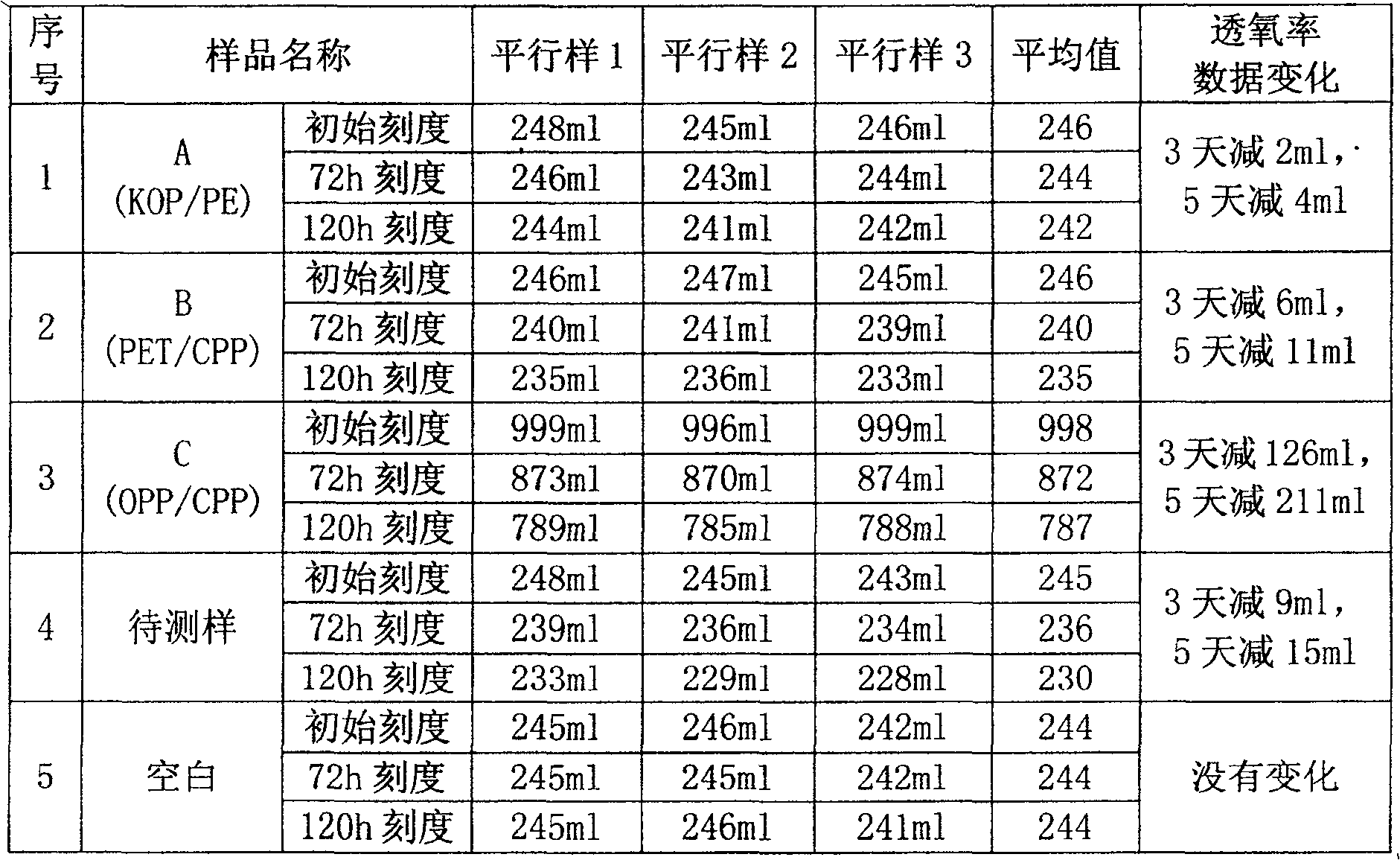

[0013] The present invention is a method for testing the oxygen permeability rate of packaging bags. Three kinds of packaging materials with different oxygen permeability rates, KOP / PE, PET / CPP, and OPP / CPP, are selected and marked with A, B, and C respectively. The properties of the three materials are as follows:

[0014] Mark A: KOP / PE 20ml / m 2 ·24h·atm low oxygen permeability

[0015] Mark B: PET / CPP 60~80ml / m 2 ·24h·atm medium oxygen permeability

[0016] Mark C: OPP / CPP 1400ml / m 2 ·24h·atm high oxygen permeability

[0017] The second step is to cut A, B, C and the packaging materials to be tested into an area of 22cm*17cm, seal them on three sides to make a bag, put in the same specification of Guangyi brand deoxidizer, and squeeze it by hand as much as possible Press to drain the air in the bag, seal it with a sealing machine, the sum of the inner area of the sealing edge is: 15cm*10cm*2 sides = 300cm 2 , three parallel experiments were done for each material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com