Wide belt sanding machine abrasive band reciprocating locus modification device

A wide-band sanding machine and reciprocating motion technology, which is applied in the field of sanding machines, can solve the problems of difficult to achieve the expected correction of the abrasive belt, not many, and the abrasive belt is detached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

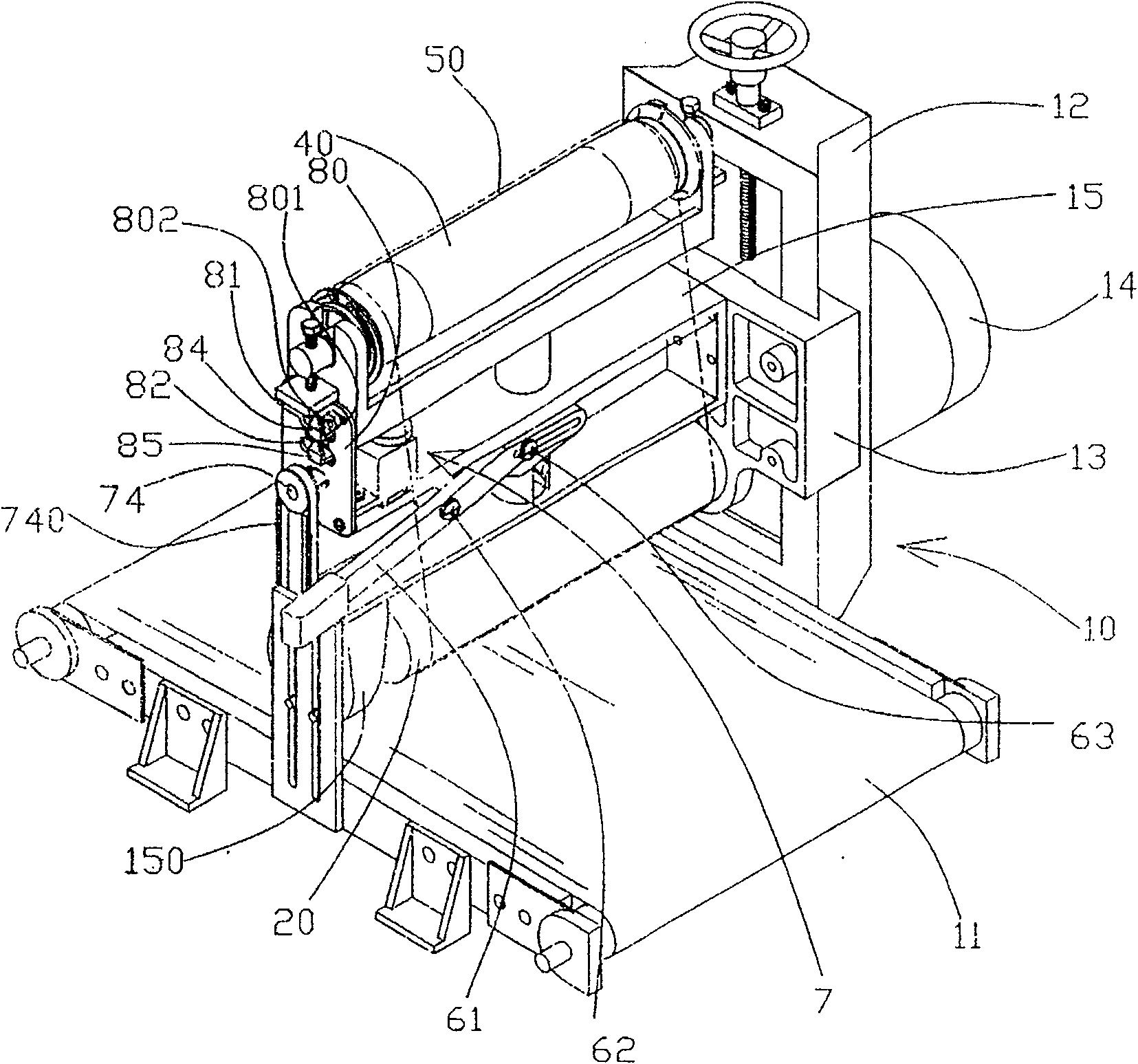

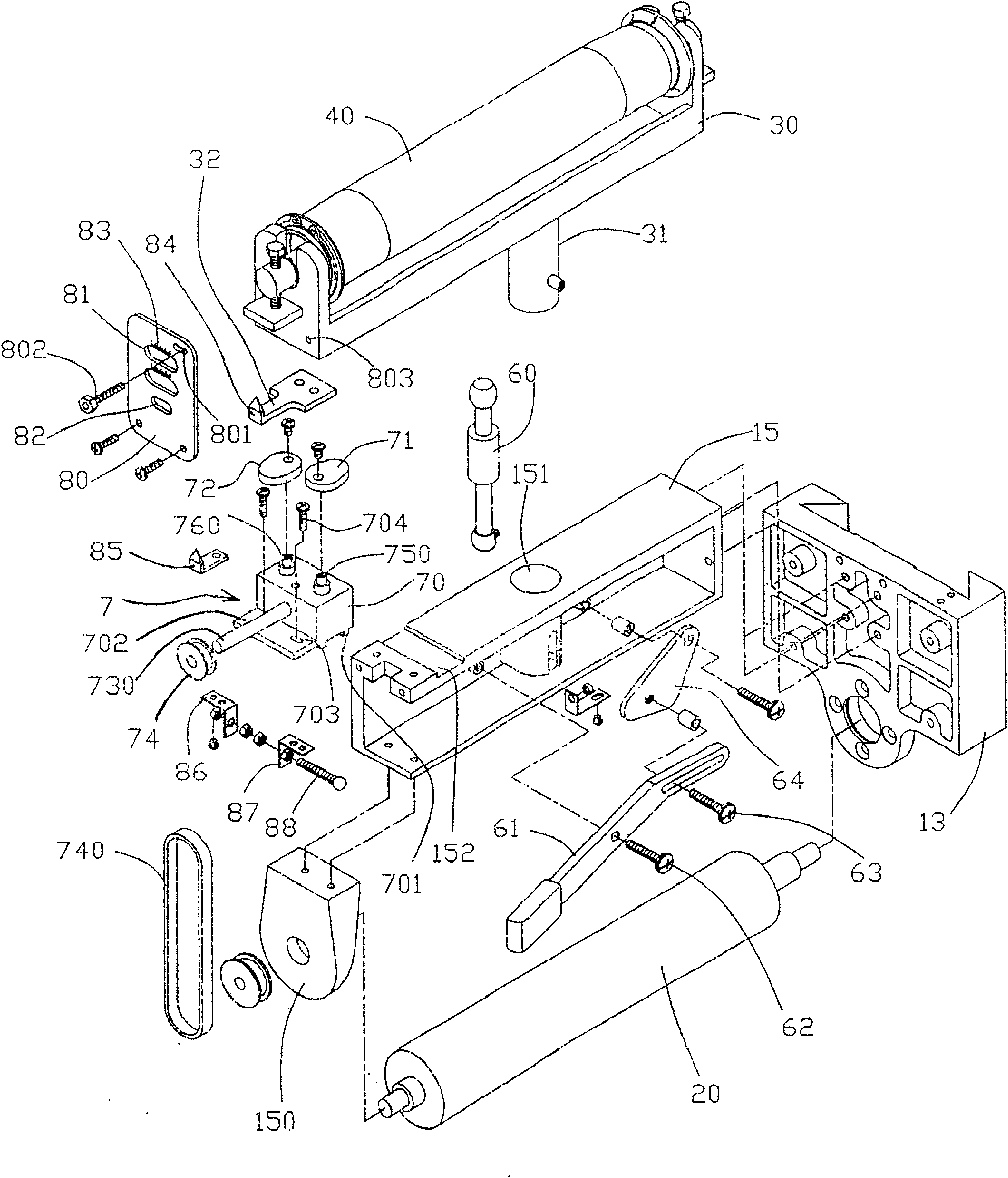

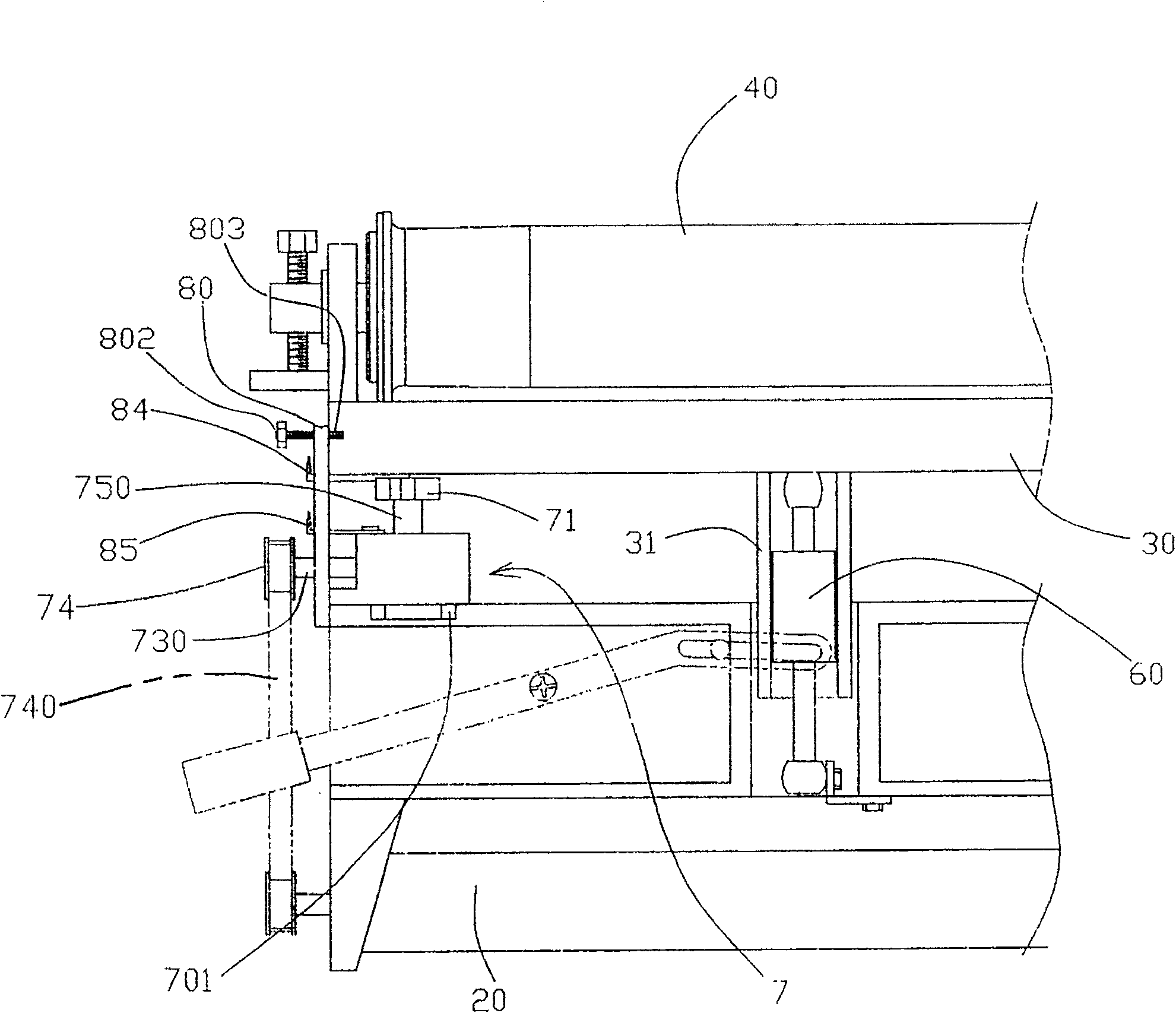

[0050] Please see figure 1 , 2 and image 3 , the sander of the present invention comprises:

[0051] A machine base 10 is used to support the sander. The base 10 has at least two rollers on the horizontally spaced pivot at the bottom, and an abrasive belt 11 is wound around the outer circumference of these rollers. Under the drive of any roller, the abrasive belt 11 11 are driven together, so that the horizontal work platform formed by the abrasive belt 11 can provide sanding on the bottom surface of the workpiece; the machine base 10 is vertically provided with a column 12 on the side of the horizontal work platform, and this column 12 is formed by the dovetail groove and the dovetail block. A sliding block 13 is arranged vertically in cooperation with the sliding block. The sliding block 13 is controlled by a screw screwed on the column 12, and can be lifted up and down for positioning. Then, a motor 14 is installed on the back of the sliding block 13, and a locking shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com