Fixing method for filter screen plug-in component in oscillation sieving machine and oscillation sieving machine of asphalt mixing apparatus

A technology of vibrating screening machine and mixing equipment, which is applied in the fields of screening, chemical instruments and methods, solid separation, etc., can solve the problems of time consumption, cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

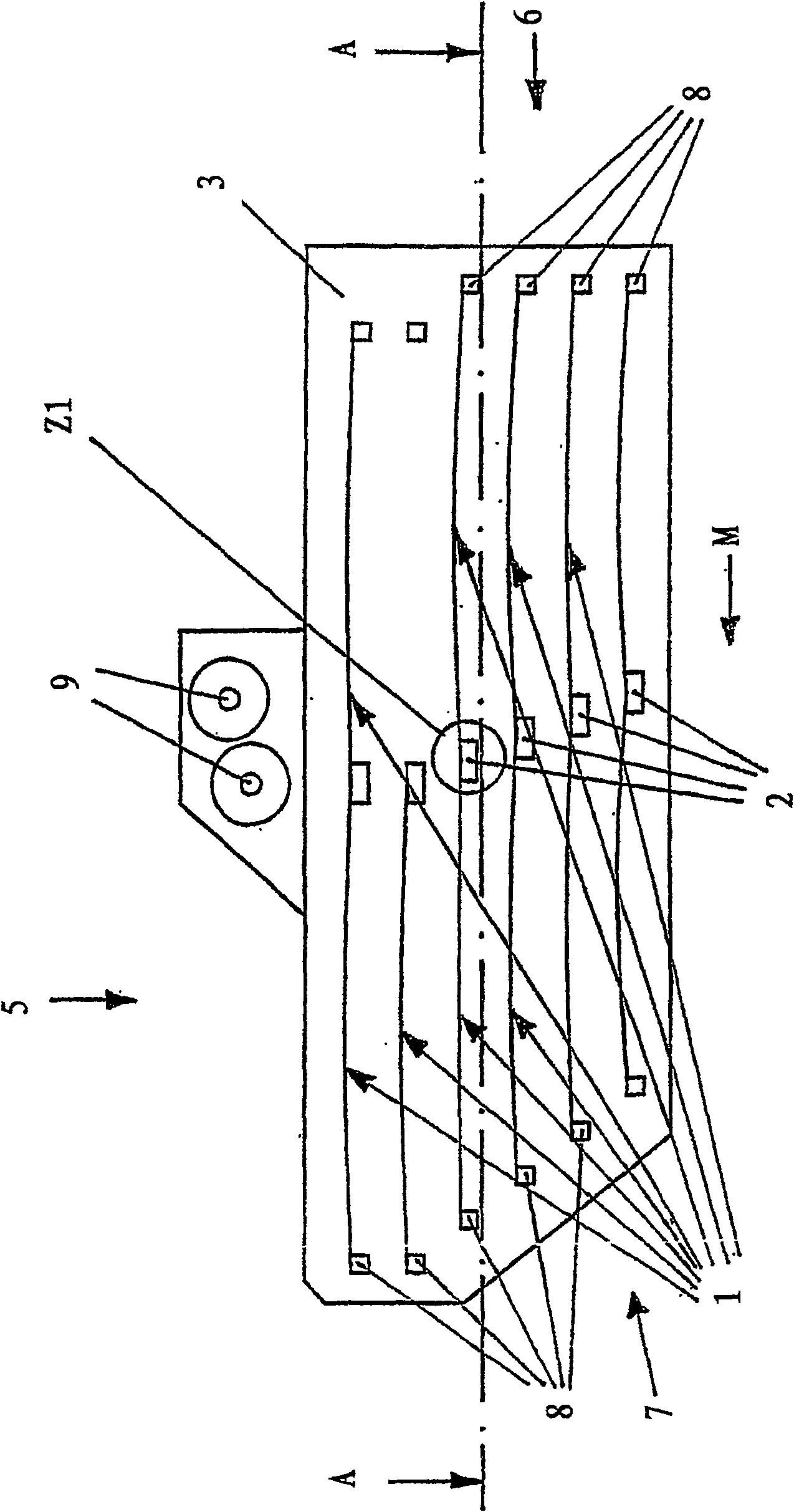

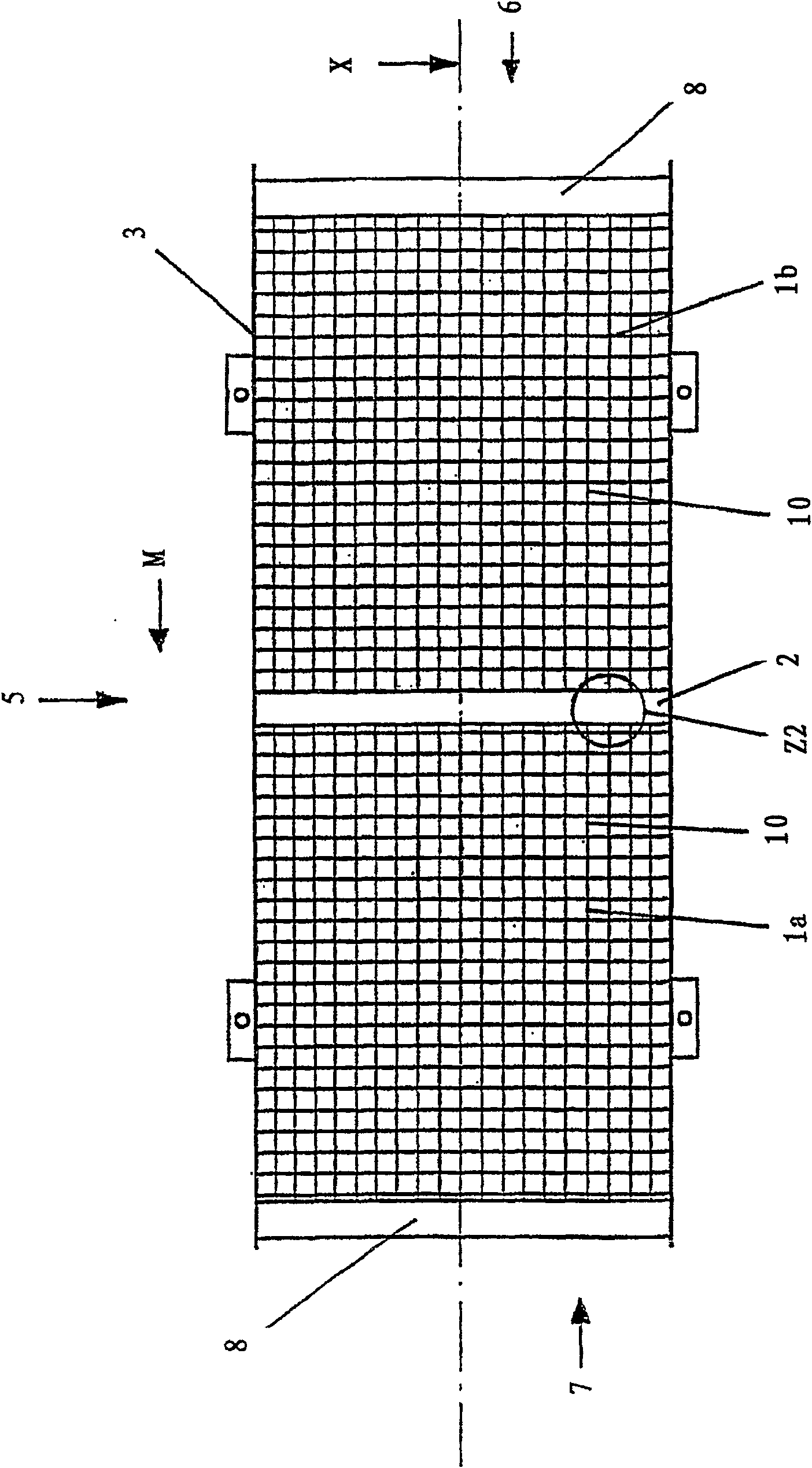

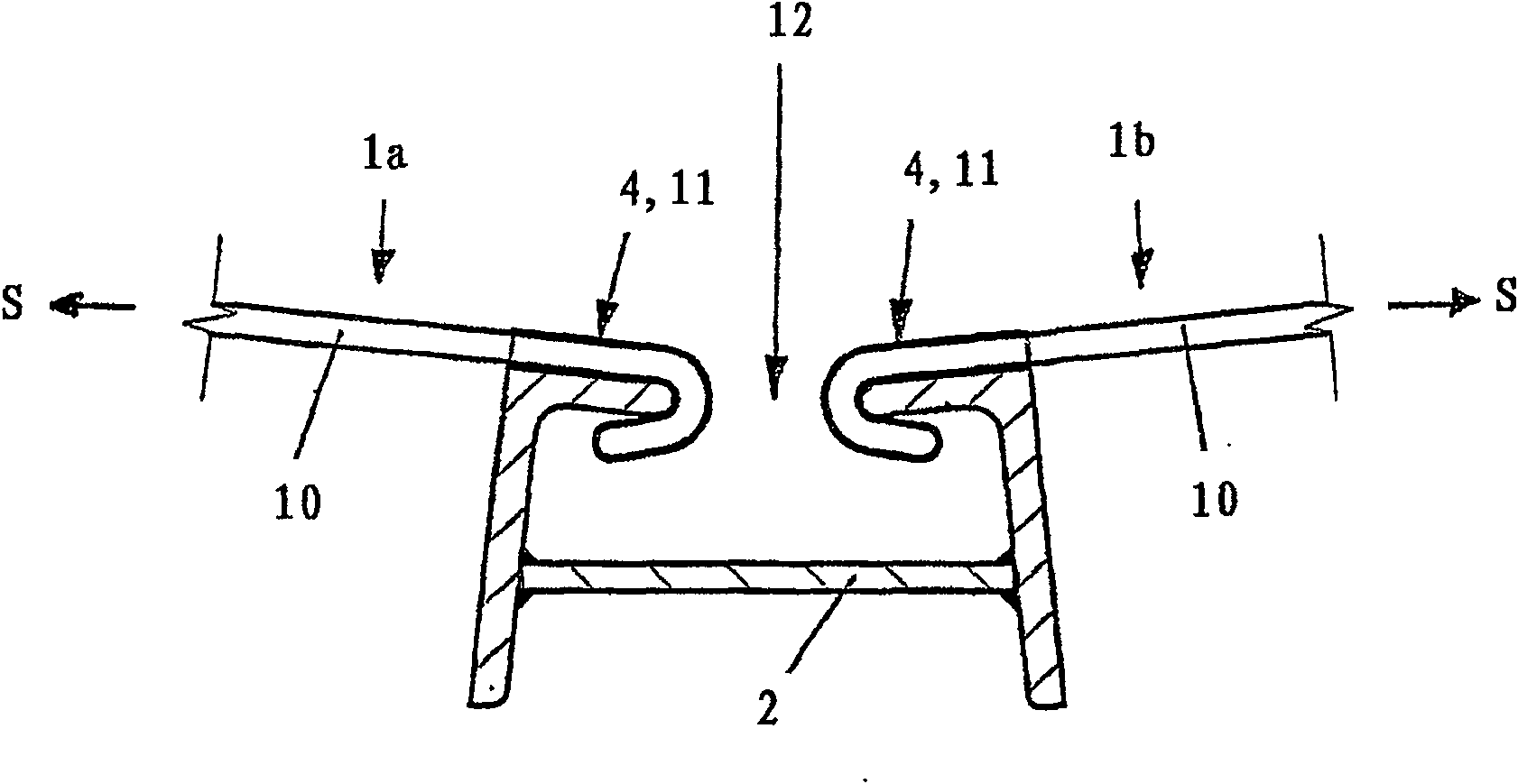

[0040] Before describing the preferred way of implementing the invention with the aid of FIGS. 2 to 7, it is first discussed Figures 1a to 1d In order to better understand the present invention, the prior art is presented.

[0041] Figure 1a A vertical section in the longitudinal direction of the fuselage 3 of a vibratory screening machine 5 is shown, as it is currently used in an asphalt mixing installation above a hot mineral silo. As can be seen, in the fuselage 3, a plurality of screen inserts 1 are stacked up and down and successively arranged, so that they form six screen panels stacked up and down in the fuselage 3, and their mesh sizes are from top to bottom. down to zoom out. The individual sieve inserts 1 of each sieve panel are each fastened to a tie rod 2 (also called intermediate tie rod) in the middle region of the body 3 and in the region of the inlet side 6 and outlet side 7 of the vibrating screen machine 5 A crossbeam 8 is tensioned respectively against a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com