Body force transferring structure for sedan

A body and car technology, applied in the field of car body structure design, to achieve the effects of ensuring living space, reducing intrusion, and reducing cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

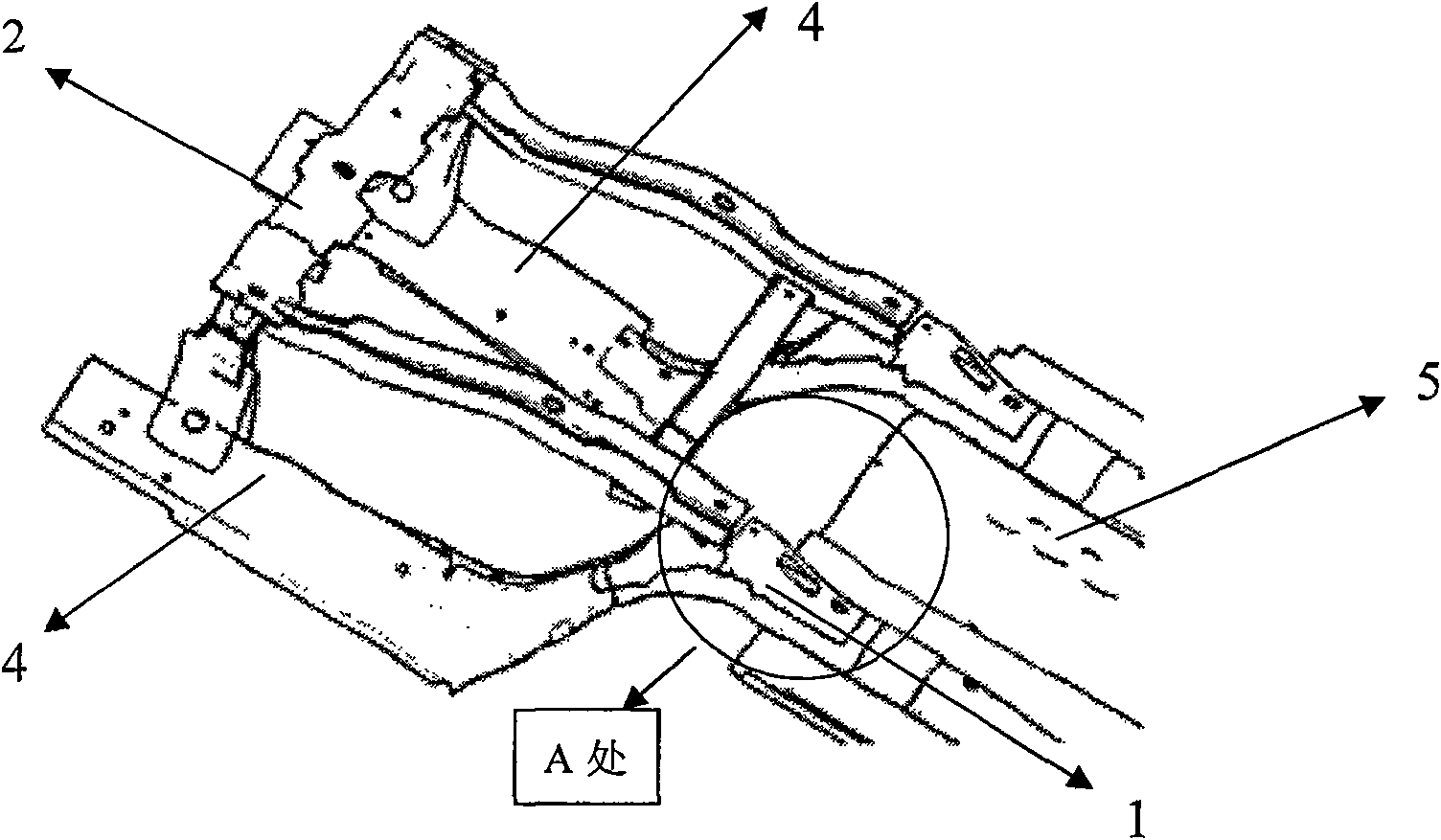

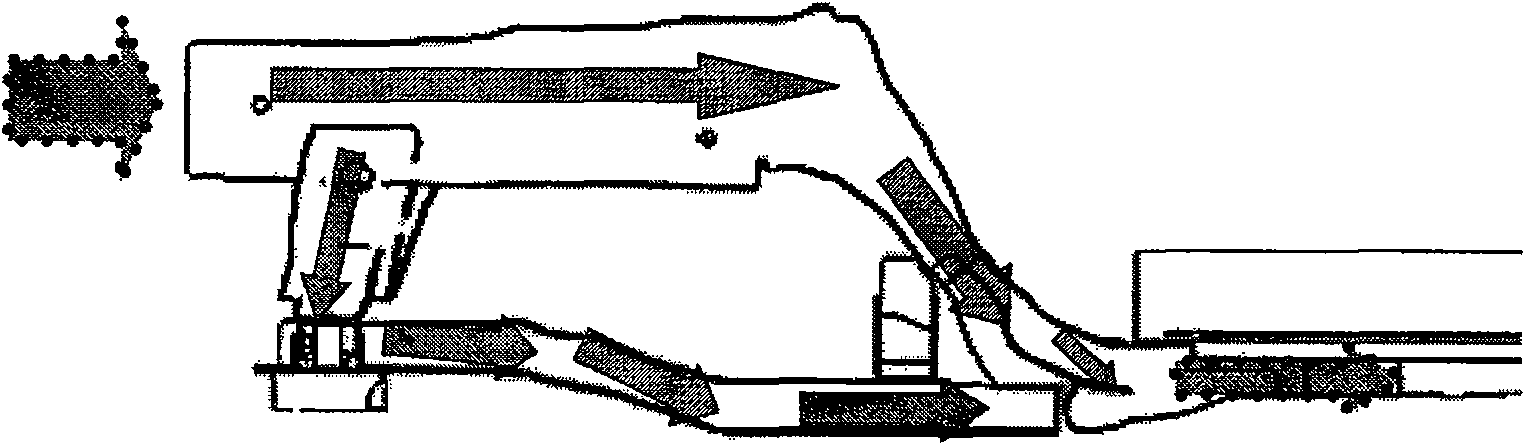

[0015] refer to figure 1 , in a preferred embodiment of the present invention, it can be seen that the vehicle body force transmission structure of the car of the present invention includes the traditional front part design of the vehicle body: sub-frame assembly 2, left and right longitudinal beam assembly 4, front floor assembly 5 ; also includes a force transmission structure 1, the force transmission structure 1 is welded on the welding assembly composed of the sub-frame assembly 2 and the front floor assembly 5, welded symmetrically from left to right, and facing the sub-frame assembly 2 In this way, a large amount of force generated by the collision will continue to be transmitted to the front floor assembly 5 through the force transmission structure 1 .

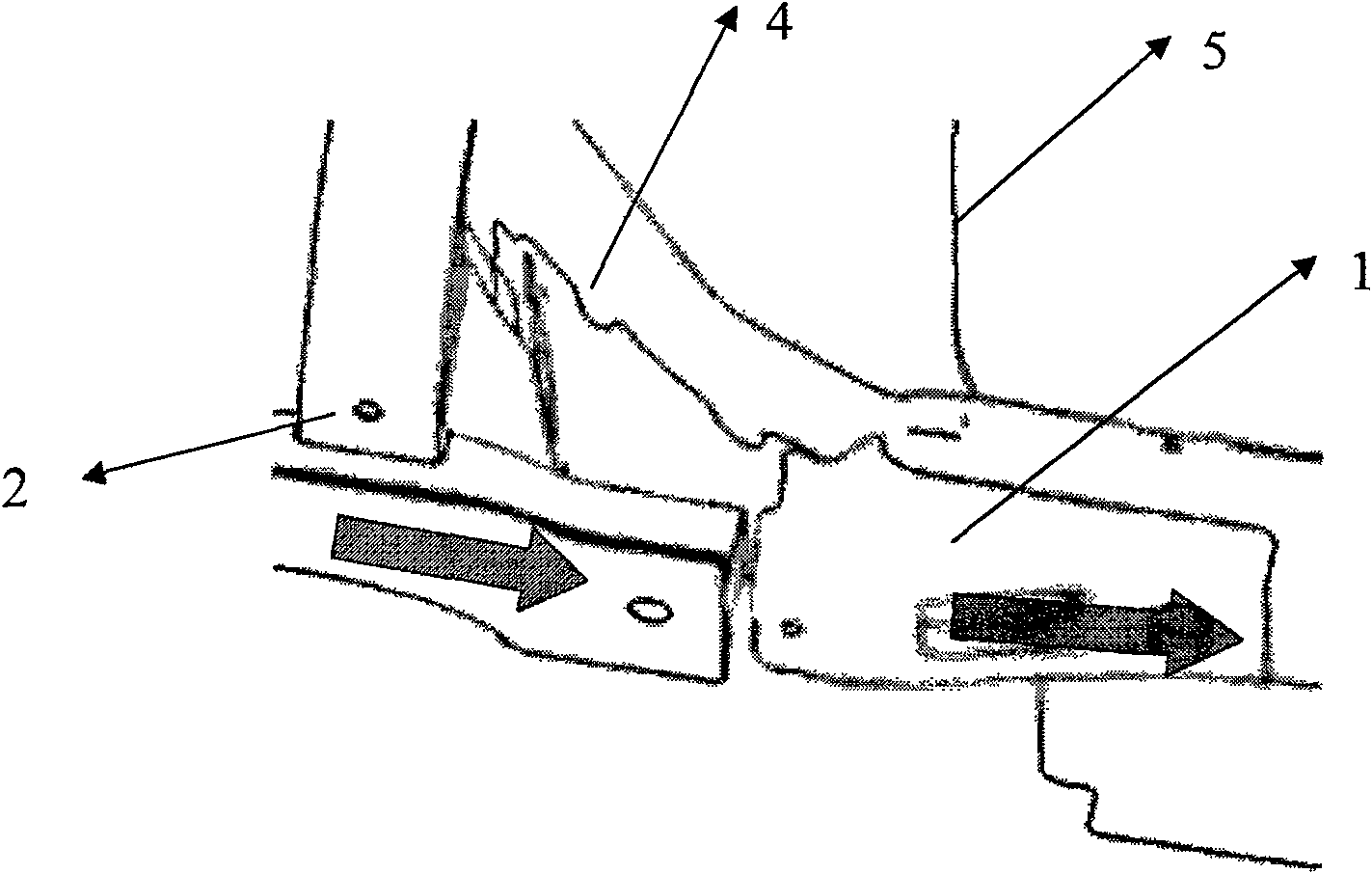

[0016] figure 2 yes figure 1 Partial enlarged view of A. The arrow system shows that the force is transmitted from the sub-frame assembly 2 of the vehicle body to the front floor assembly 5 in the middle of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com