Calibration method for object surface three-dimensional contour structure light measurement system

A technology of three-dimensional contour and object surface, which is applied in the direction of measuring device, optical device, image data processing, etc., can solve the problems of affecting the accuracy and not being able to obtain the target pattern, and achieve the effect of improving the calibration accuracy and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings. The invention uses a simple color plane target for the first time to calibrate all the parameters of the camera and the projector of the structured light vision measurement system.

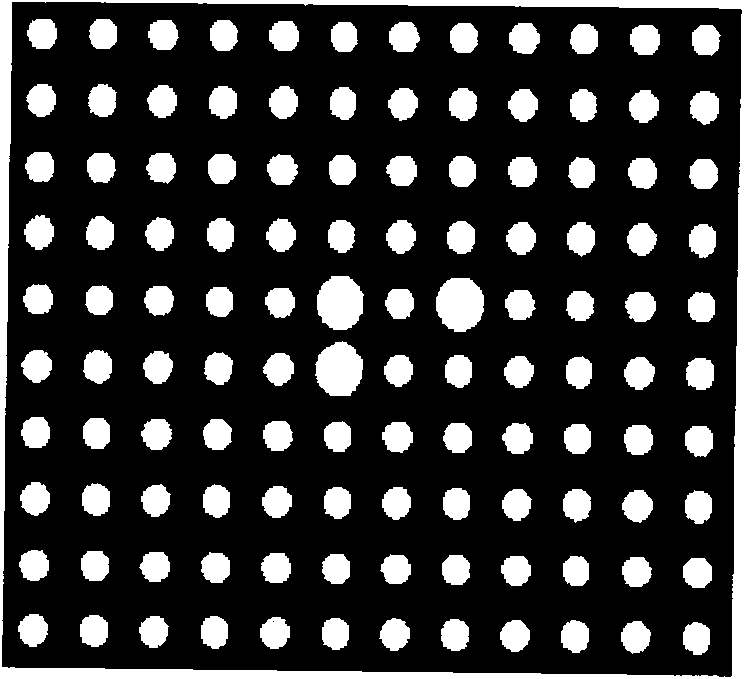

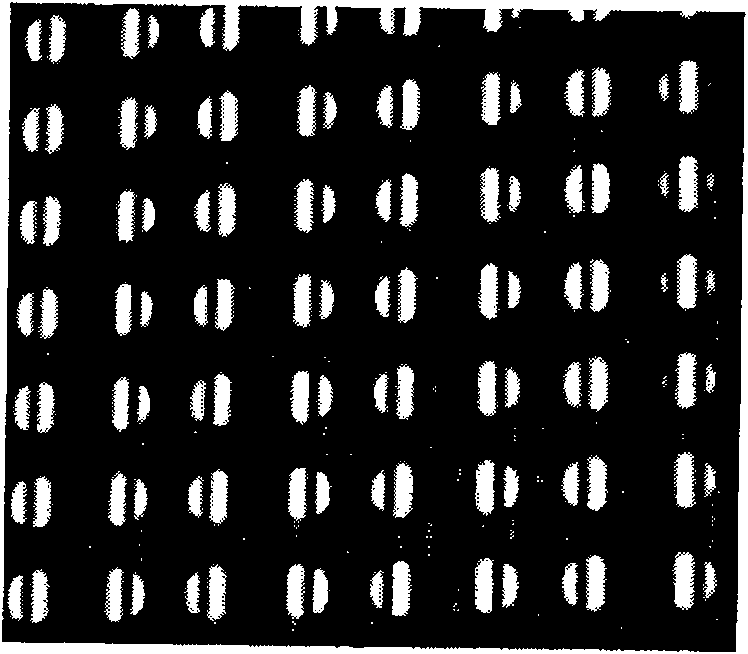

[0022] Target board fabrication. figure 1 It is the color target of the present invention, the circular target, that is, the foreground color is red, and the background color of the target plate, that is, the background color is blue. The target is to print colored target dots on a diffuse reflective cellophane and paste them on a flat plate with a flatness less than 0.01. The target dot array is M×N, the rows and columns are strictly vertical, and the center distance of the circular holes is equal and known (Δx , Δy), the difference from the traditional target is that the target of the present invention is in color, and the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com