Equipment for preparing dropping pill with air cooled by cold trap

A technology of cooling gas and dripping pills, which is applied in the direction of dividing liquid into bead droplets and granulating, making medicines into special physical or taking forms, etc. It can solve the problem that the equipment cannot be completely cleaned, organic residues, and cooling liquid residues cannot be solved. and other problems, to achieve the effect of no cleaning dead angle, conducive to stability and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The equipment for preparing dropping pills using cold trap cooling gas of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The structure of the present invention adopts low-temperature air as the cooling medium, usually at a temperature lower than 0 degrees, to contact with the molten dripping auxiliary material, and cool it down below the freezing point to ensure the formation of the dripping pill.

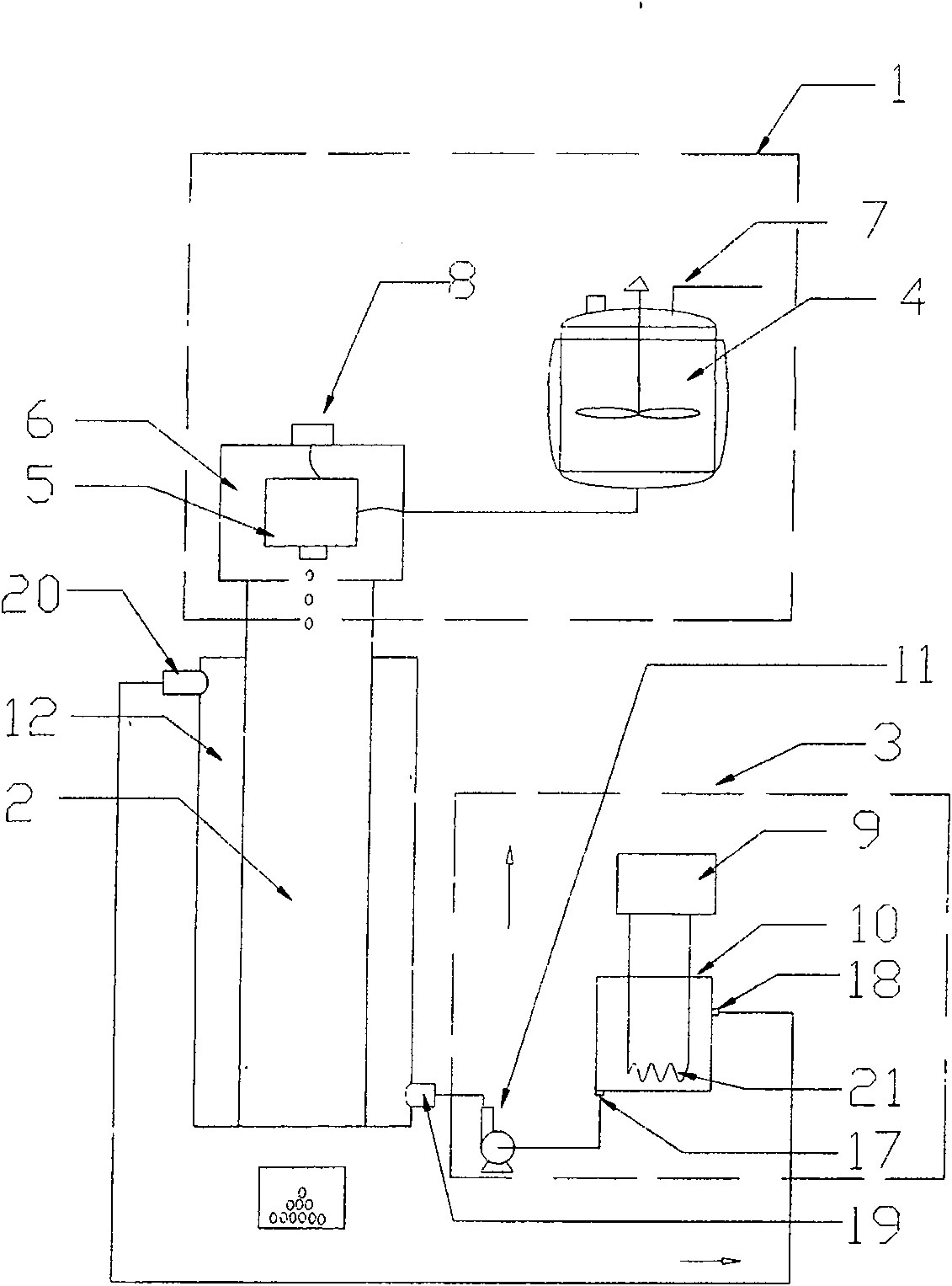

[0029] Such as figure 1 Shown, the equipment that utilizes cold trap cooling gas of the present invention to prepare dropping pills includes: dropping pill device 1, the cooling pipeline 2 that is sealed and communicated with dropping pill device 1, and is connected with cooling pipeline 2 and circulates to cooling pipeline 2 Refrigeration device 3 that delivers refrigerant to the outside.

[0030] The dripping pill device 1 includes: a chemical material tank 4 communicated with the pipeline 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com