Thick steel sheet having excellent HAZ toughness for super high input heat and parent material toughness for low temperature

A technology of thick steel plate and toughness, which is applied in the field of thick steel plate with excellent toughness of low temperature base material, and can solve the problems of HAZ toughness deterioration and coarse structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

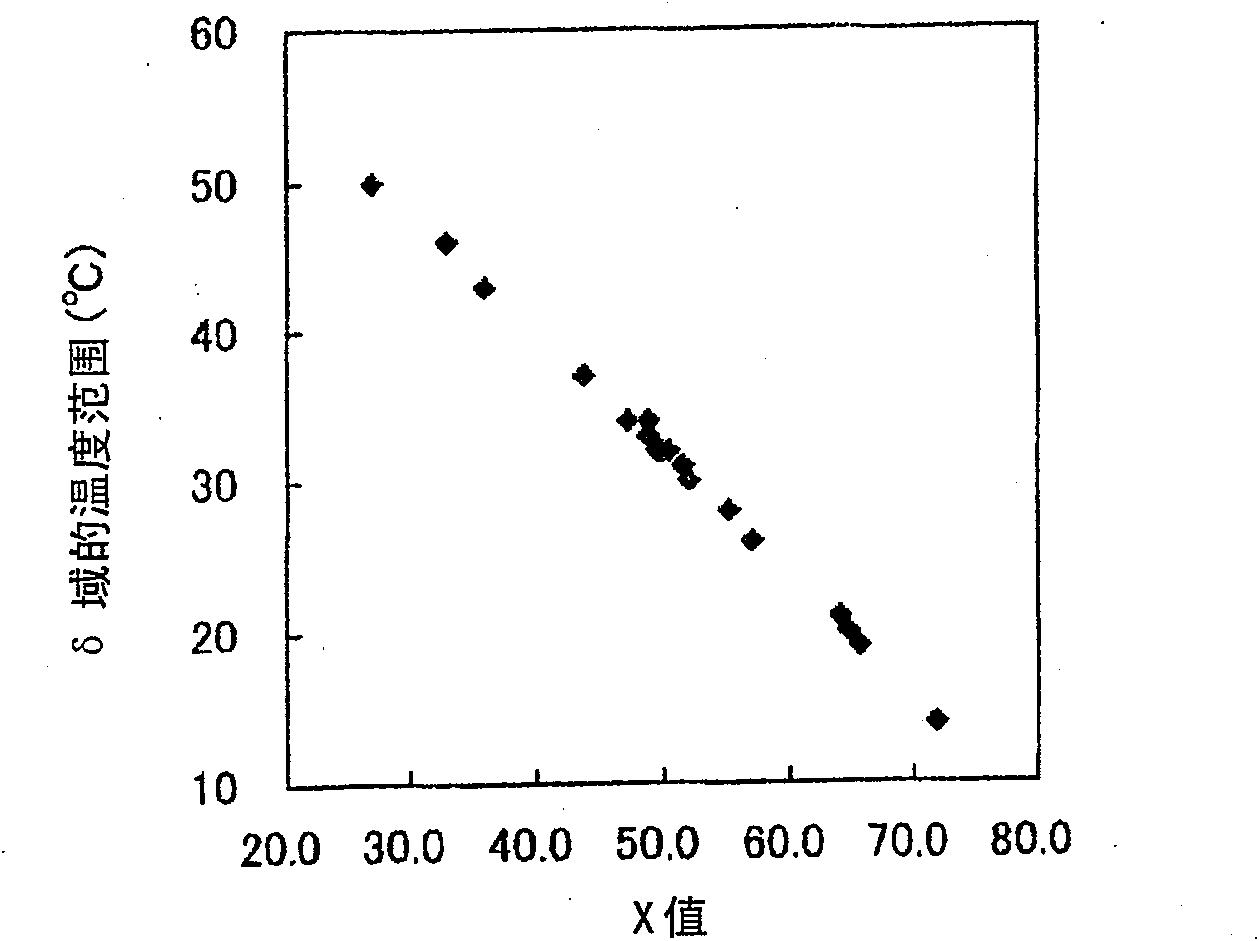

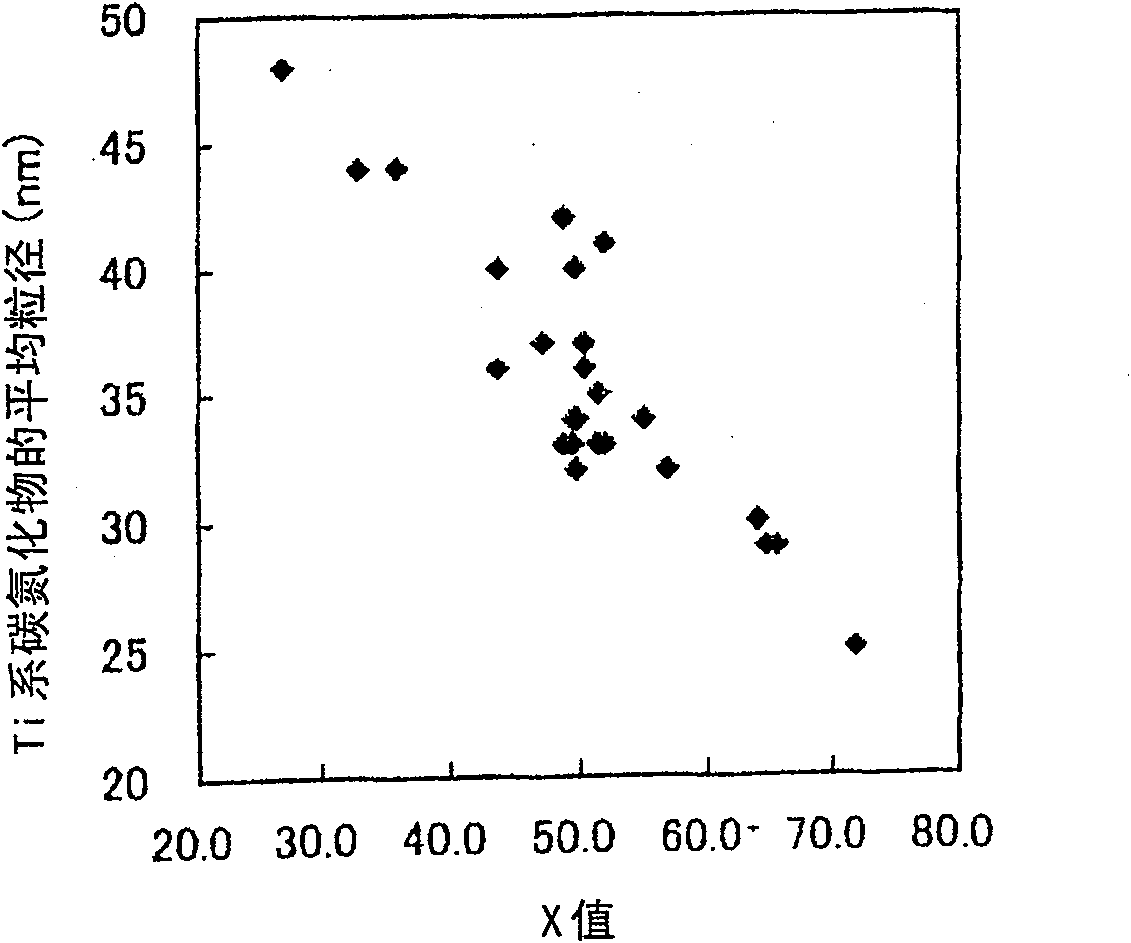

[0029] The inventors of the present invention attempted to achieve good HAZ toughness even in ultra-high heat input welding by making Ti-based carbonitrides finer. It is considered that the dispersion state of conventional Ti-based carbonitrides can be determined only by the addition balance of Ti and N if the cooling rate at the time of solidification of molten steel is constant. However, as a result of intense research by the present inventors, it has been revealed that Ti-based carbonitrides can be finely dispersed even with the same Ti and N additions by narrowing the temperature range of the δ region shown in the steel state diagram.

[0030] The so-called "delta region" here means the region containing delta iron in the state diagram of steel. The "region containing δ iron" includes not only a region of δ iron but also a region of a state different from δ iron, such as a δ+γ two-phase region. Then, the "delta domain temperature range" refers to the temperature range inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com