Sintering combustion automatic analysis instrument

An automatic analyzer and measuring instrument technology, applied in the field of laboratory instruments, can solve the problems of difficult large-capacity analysis, cumbersome steps, low accuracy, etc., and achieve the effect of high degree of automation, large analysis capacity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

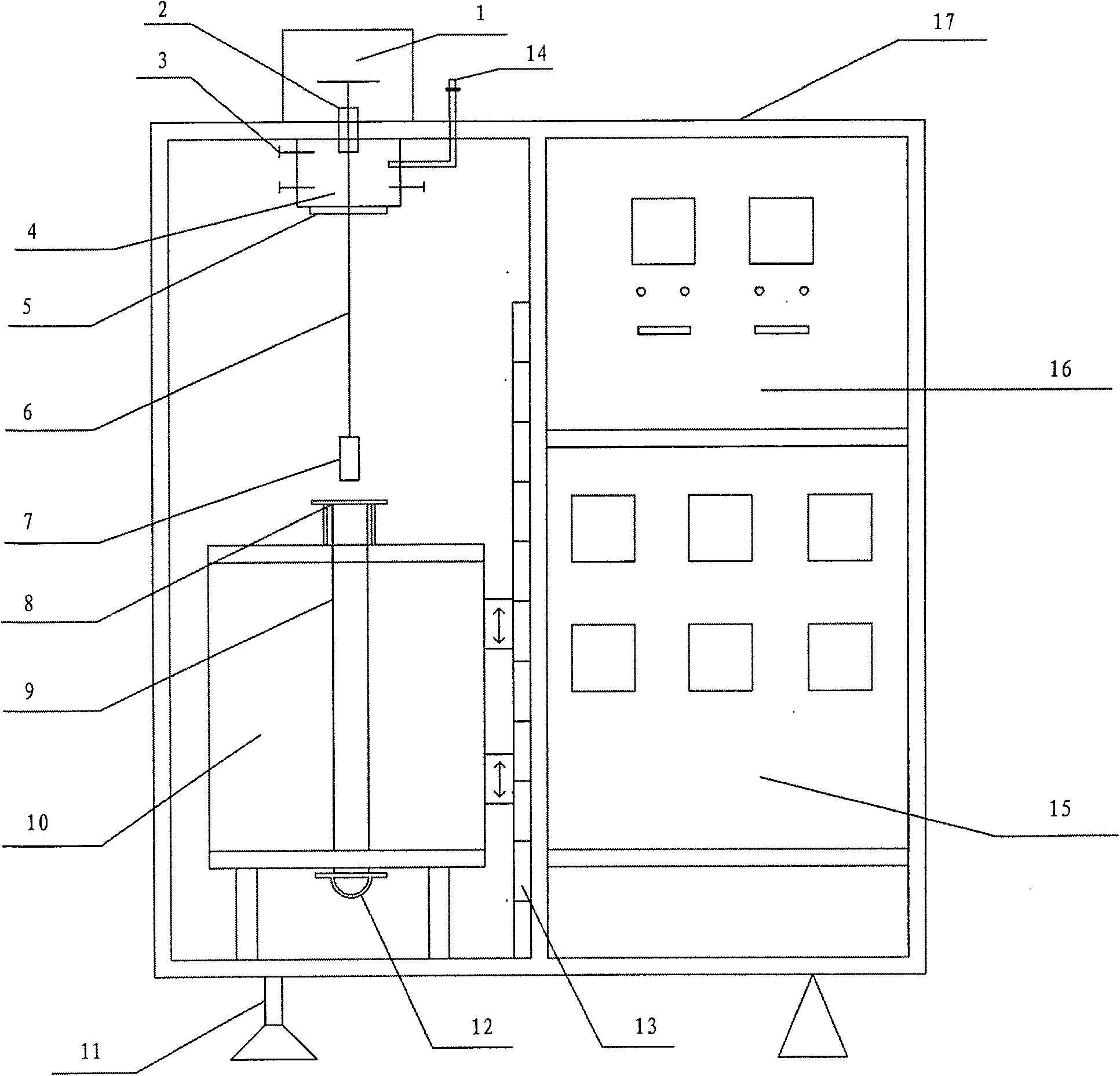

[0011] The specific embodiment of the invention is described with reference to the accompanying drawings.

[0012] as attached figure 1 Shown: it comprises frame 17, electronic balance 1, resistance furnace 10, measuring instrument 15 and temperature controller 16, and electronic balance 1 is arranged on the top of frame 17, and it is connected with measuring instrument 15, on the top of frame 17 A gas collection chamber 4 is provided, the lower part of the gas collection chamber 4 is provided with a fixed flange 5, and a lifting frame 13 is provided on the frame 17, and the resistance furnace 10 is vertically arranged on the lifting frame 13, and the lifting frame 13 can drive the resistance furnace Moving up and down. The furnace tube 9 is vertically installed in the furnace, and a metal hanging basket 7 for placing the crucible is set on the hook at the bottom of the electronic balance 1, and the top of the hanging basket 7 is connected with the hook of the electronic bala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com