Water spreading method cable laying robot propulsion mechanism

A technology of cable laying and propulsion mechanism, which is applied in the field of robots, can solve problems such as irregular cable shape and no detection, and achieve the effects of convenient control, simple and convenient operation, and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0037] This embodiment is used for laying cables 18 of 35-105 mm.

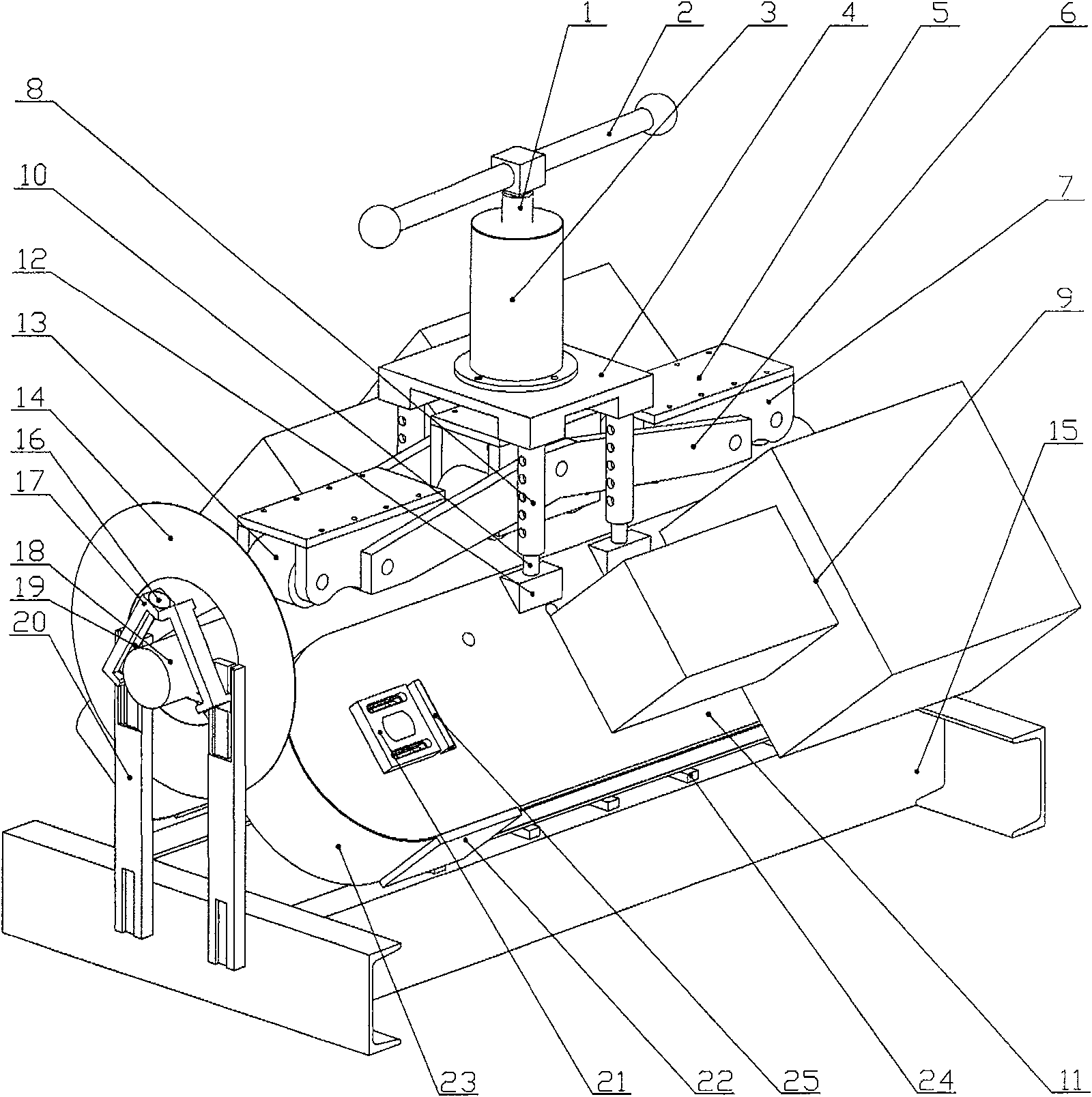

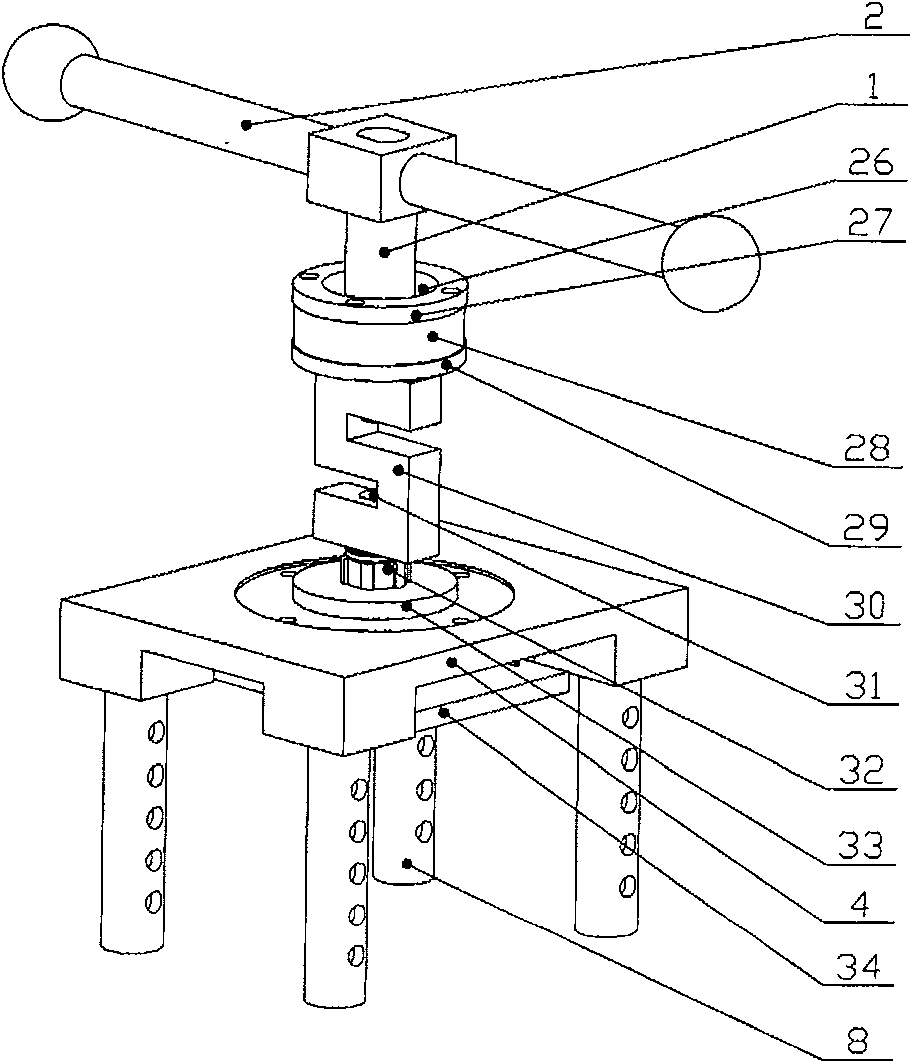

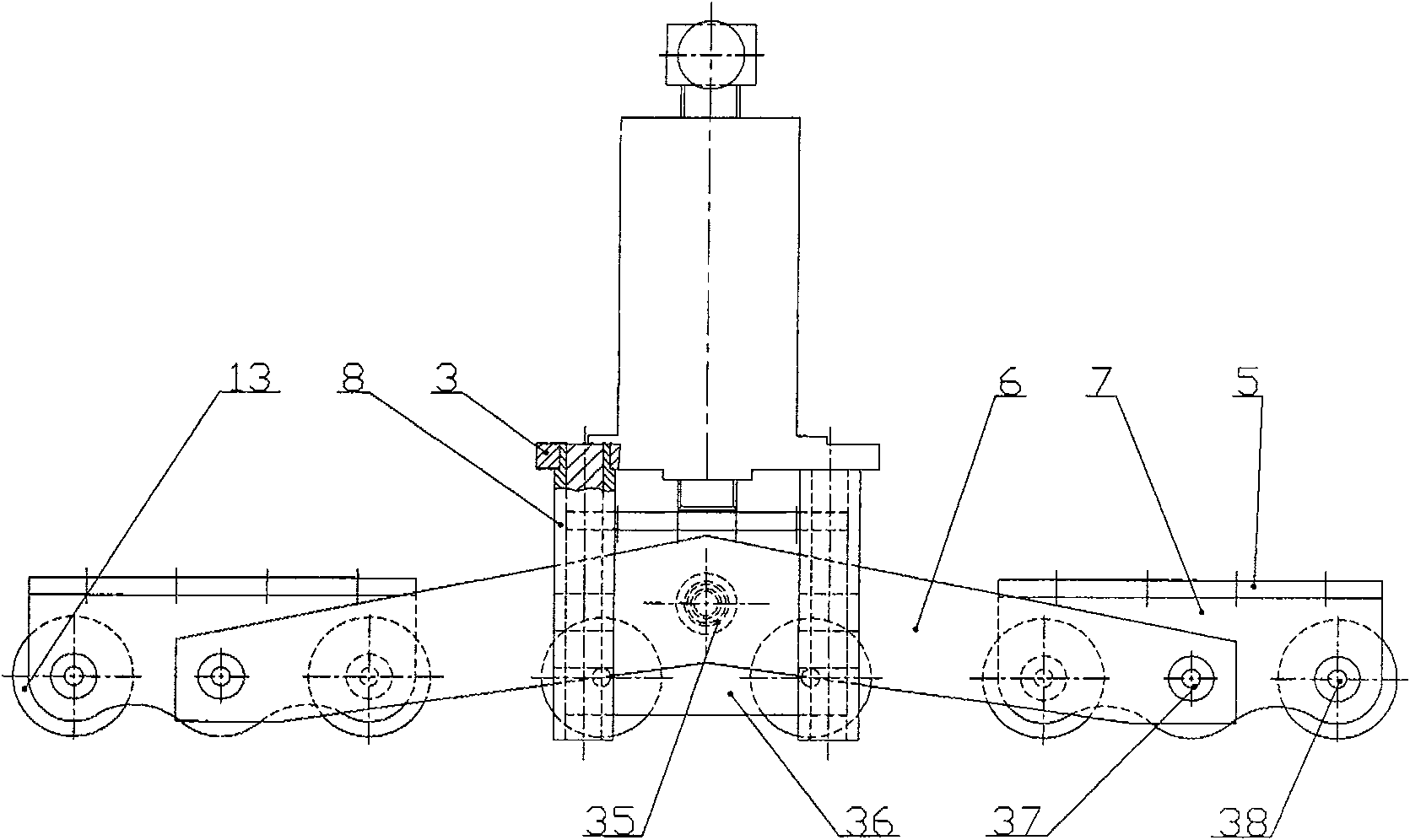

[0038] like figure 1 As shown, this embodiment includes: a pressing mechanism, two push boxes, an upper and lower connection mechanism, a pipe butt joint mechanism, and a bottom support mechanism, wherein:

[0039] The pressing mechanism is connected with the two push boxes through the upper and lower connection mechanism. The two push boxes are placed symmetrically about the center line of the cable to form a V-shaped space, and are respectively located below the two sides of the cable. The pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com