Woolen plush cloth and method of manufacture

A flannel and long-haired technology, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of poor expansion and contraction balance, unfavorable suppression of fluff, fluff fragments, etc., to ensure comfortable seating, excellent softness, and prevent tooth baring Effect

Inactive Publication Date: 2010-11-24

SUMINOE TEXTILE CO LTD +1

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the obtained fabric is excellent in stretchability and can prevent tooth baring to a certain extent, the balance of stretching and stretching in the warp and weft directions is poor, and the surface of the fabric is uneven and crooked in the stage before installation. The above-mentioned unevenness or curvature becomes an obstacle when cutting or sewing, causing a problem of poor workability, and a problem of poor appearance quality due to the unevenness on the surface of the fabric after laying.

Moreover, because the stretchability of the ground structure is too large, it is not conducive to suppressing the fluff during weaving, and it is easy to cause defects such as fragments of the fluff when the two sides are divided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

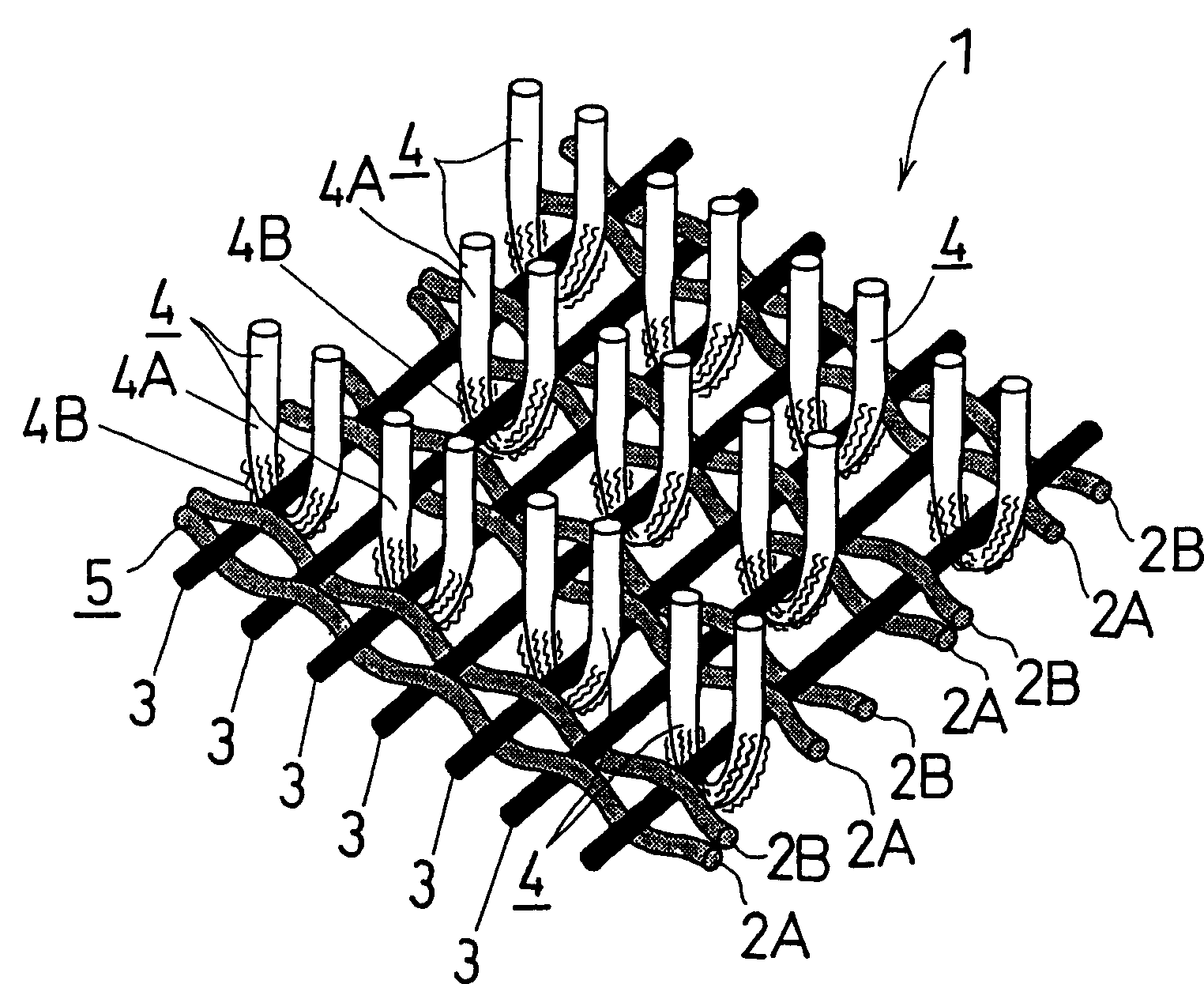

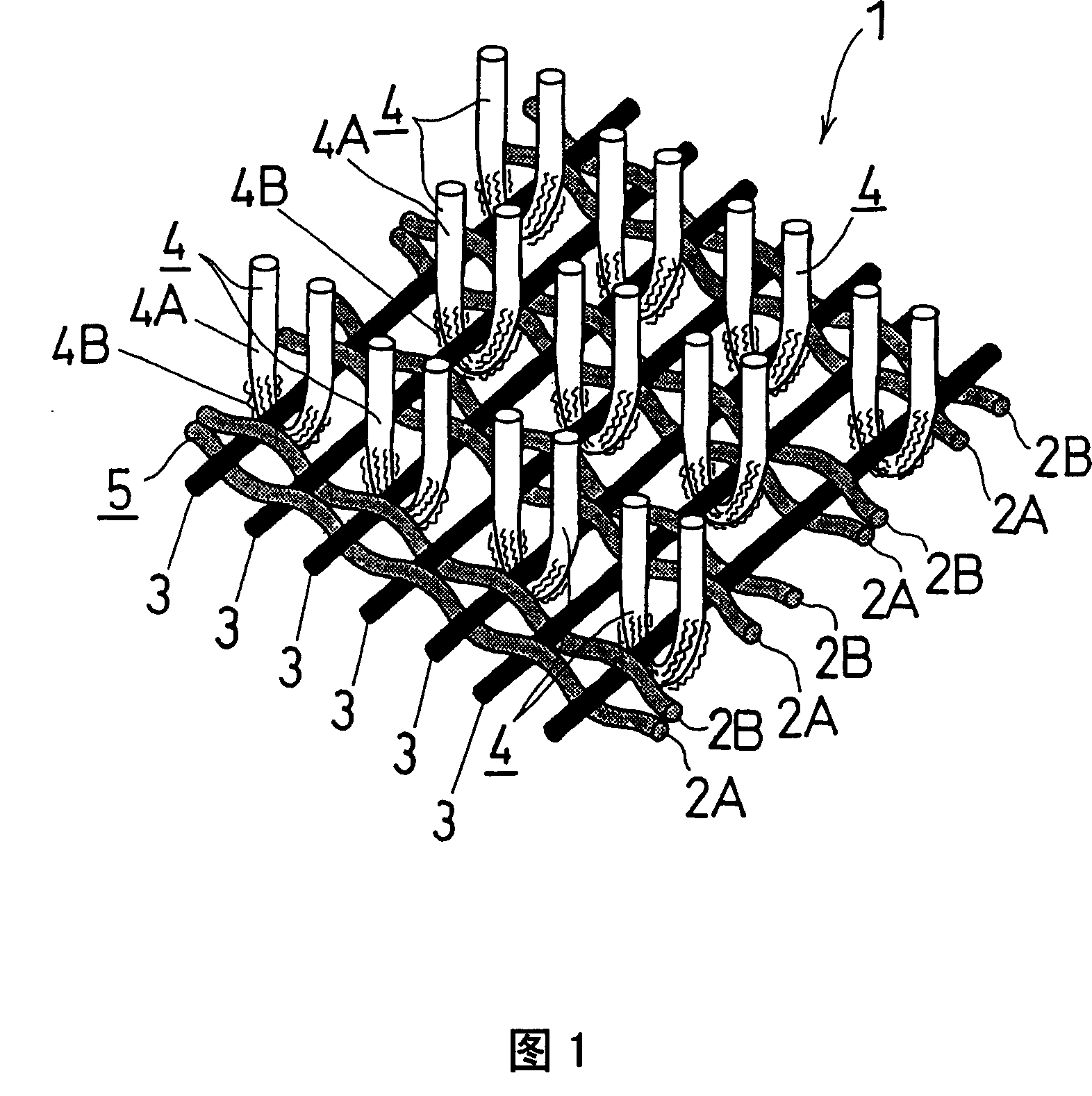

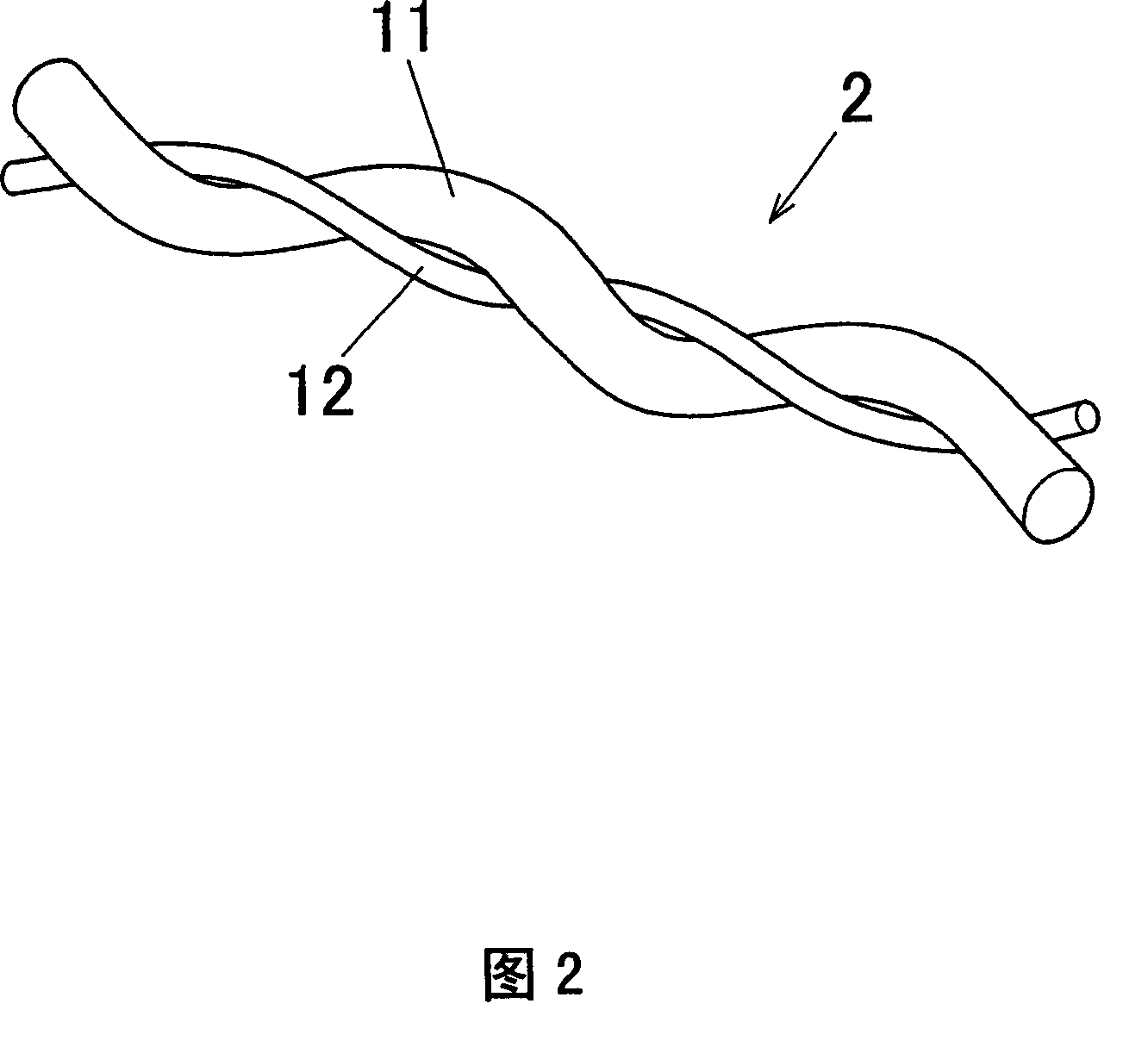

The invention relates to a plush cloth, which is characterized in that in a plush cloth which is got through implanting a knitting wool (4) in a ground weave (5) which is formed through weaving a longitude line (2) in a latitude line (3), at least elastic yarn is utilized to be the longitude line (2), winding complex wire is utilized to be the latitude line (3), and the winding complex wire windscorkscrew yarn which is constituted by non-water-soluble fiber on a core line which is constituted by water-soluble fiber in a winding status, and meanwhile, in order to keep the winding status, a padding thread which is constituted by water-soluble fiber is composited to get, or cabling complex wire can be used to be the latitude line (3), and the cabling complex wire is cabled by a core line which is constituted by corkscrew thread which is formed by water-soluble fiber and non-water-soluble fiber. When the plush cloth is paved according to bending shape, curved surface shape and other complex shapes, and the phenomenon of grinning is not easy to happen, and the invention is ensured to have higher appearance grade, and meanwhile, the surface of cloth is not unsmooth, and attaching is excellent.

Description

Plush fabric and manufacturing method thereof This application claims the priority of Japanese Patent Application Japanese Patent Application No. 2005-15787 filed on January 24, 2005, and the contents disclosed therein may directly constitute a part of the present invention. technical field The present invention relates to a plush fabric which can be suitably used, for example, as a cover material for seat pads of automobiles and as a cover material for chairs for furniture. Background technique Plush fabrics such as furniture moquettes have been used as surface materials for seat pads of automobiles and trains, and as surface materials for chairs for furniture. In the past common furniture pile fabric skin material, what use is polyamide, polyester, acrylic fiber, wool etc. non-elasticity thread (referring to Japanese Patent Laid-Open No. 5-279963 communique). When using furniture pile fabric to constitute the material for the seat pad of an automobile, as shown in FIG...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D03D15/00D03D27/00D02G3/32D02G3/38D03D15/56

Inventor 上村知行泽田大辅丰田笃史

Owner SUMINOE TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com