Assistant glue dispensing equipment

A technology of auxiliary points and lens barrels, applied in installation, optics, instruments, etc., can solve problems such as positioning unit displacement, striker, and shaft eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

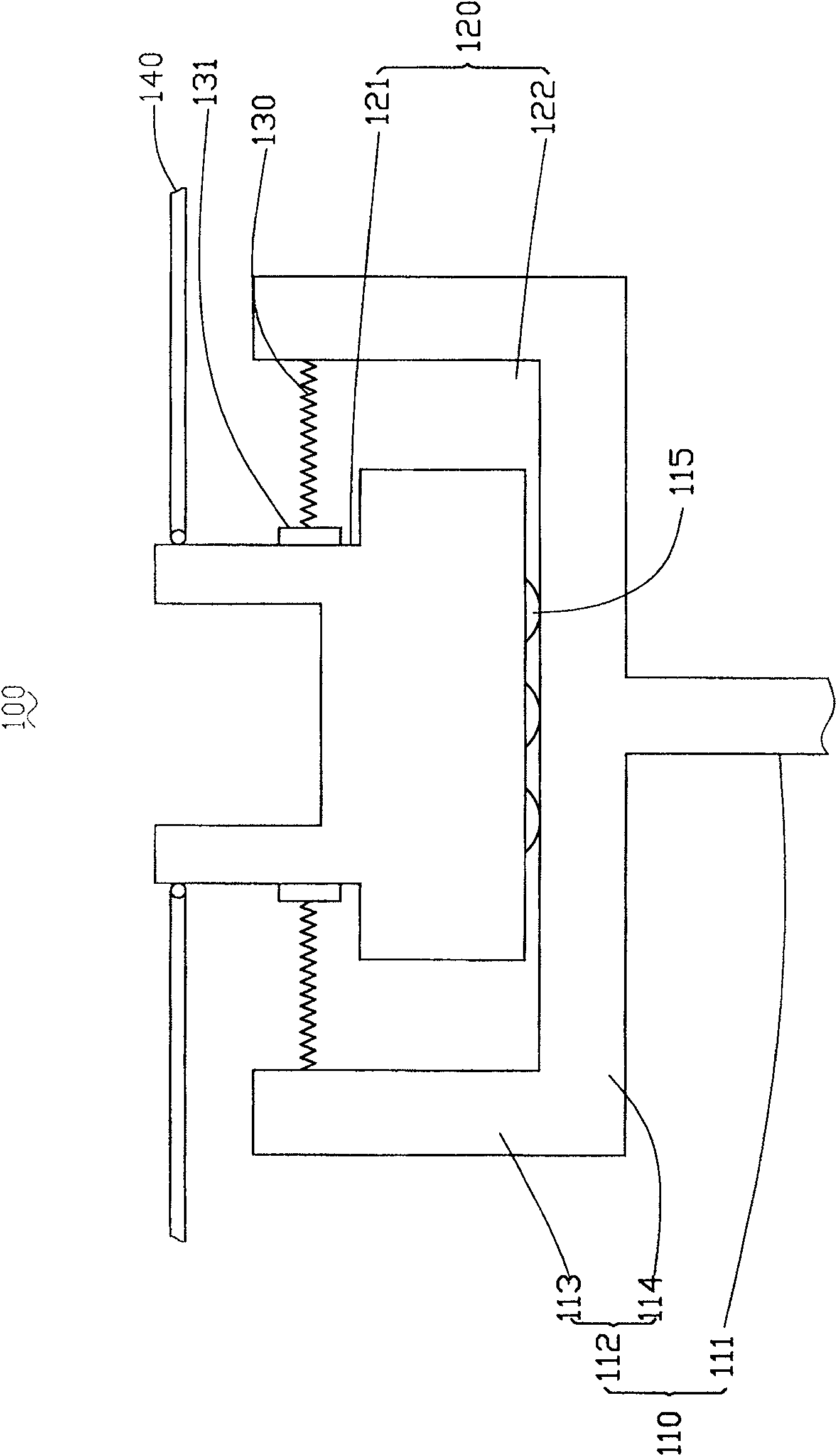

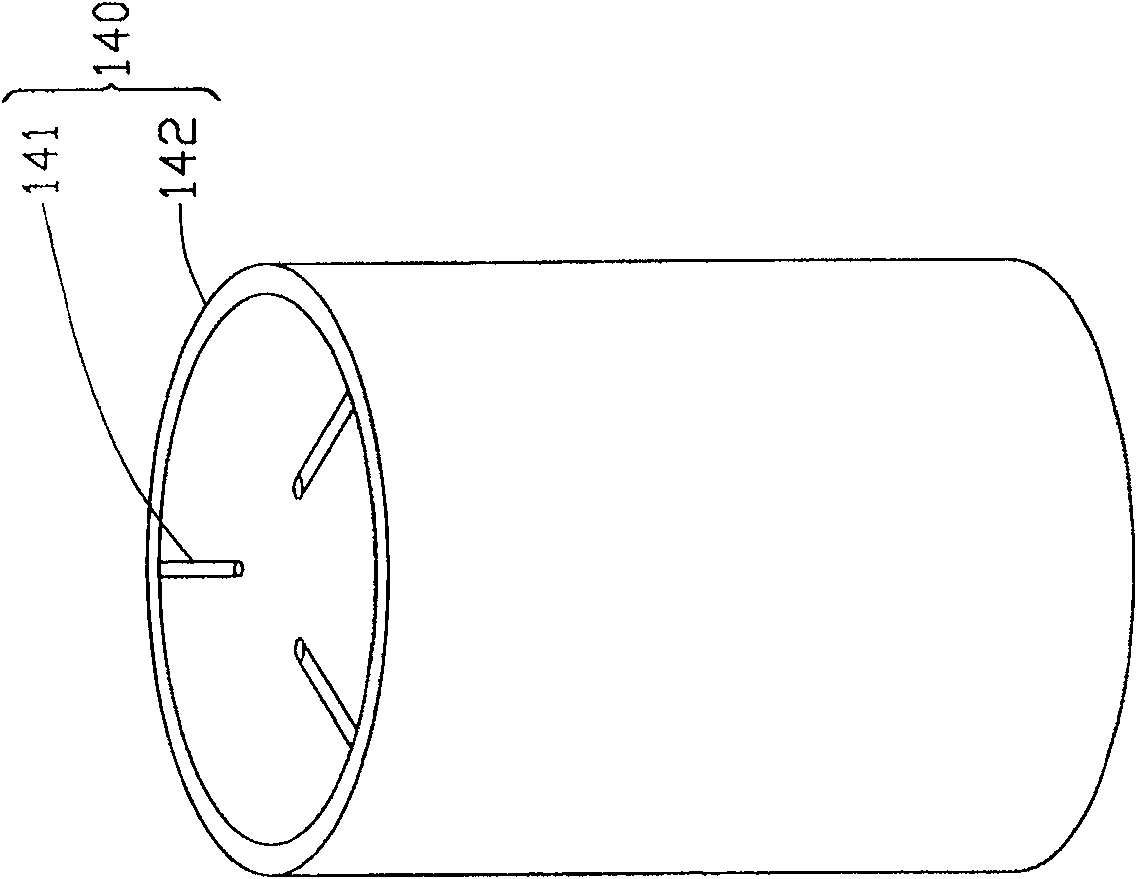

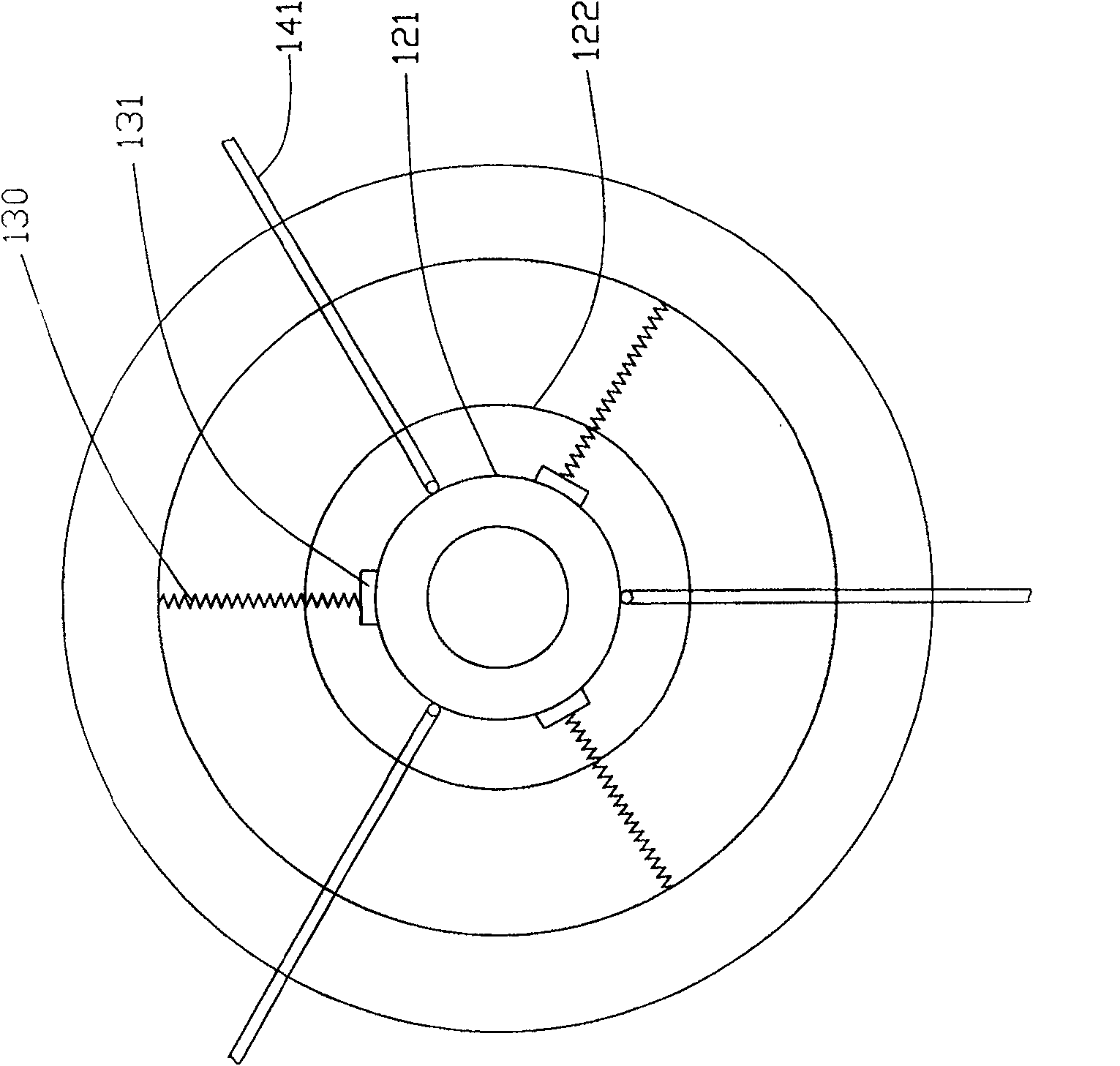

[0013] Such as figure 1 As shown, the embodiment of the technical solution provides an auxiliary dispensing device 100 , which includes a rotating stage 110 , a lens barrel fixing mechanism 120 , at least one elastic connecting body 130 and a positioning member 140 . The rotating stage 110 includes a rotating shaft 111 and a supporting portion 112 , the rotating shaft 111 is perpendicular to the supporting portion 112 and is arranged on the axis of the supporting portion 112 . The lens barrel fixing mechanism 120 is disposed on the support portion 112 of the rotary stage 110 . The lens barrel fixing mechanism 120 can be arranged coaxially with the supporting part 112 or not, as long as the lens barrel fixing mechanism 120 can rotate by itself through the rotation of the rotating shaft 111 . In this embodiment, the lens barrel fixing mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com