Coupling electrode for capacitive voltage tapping within the insulation body of insulated sheath or bearing

A technology of coupling electrodes and insulators is applied in the field of coupling electrodes, which can solve the problems of fixing the coupling electrodes and affecting the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

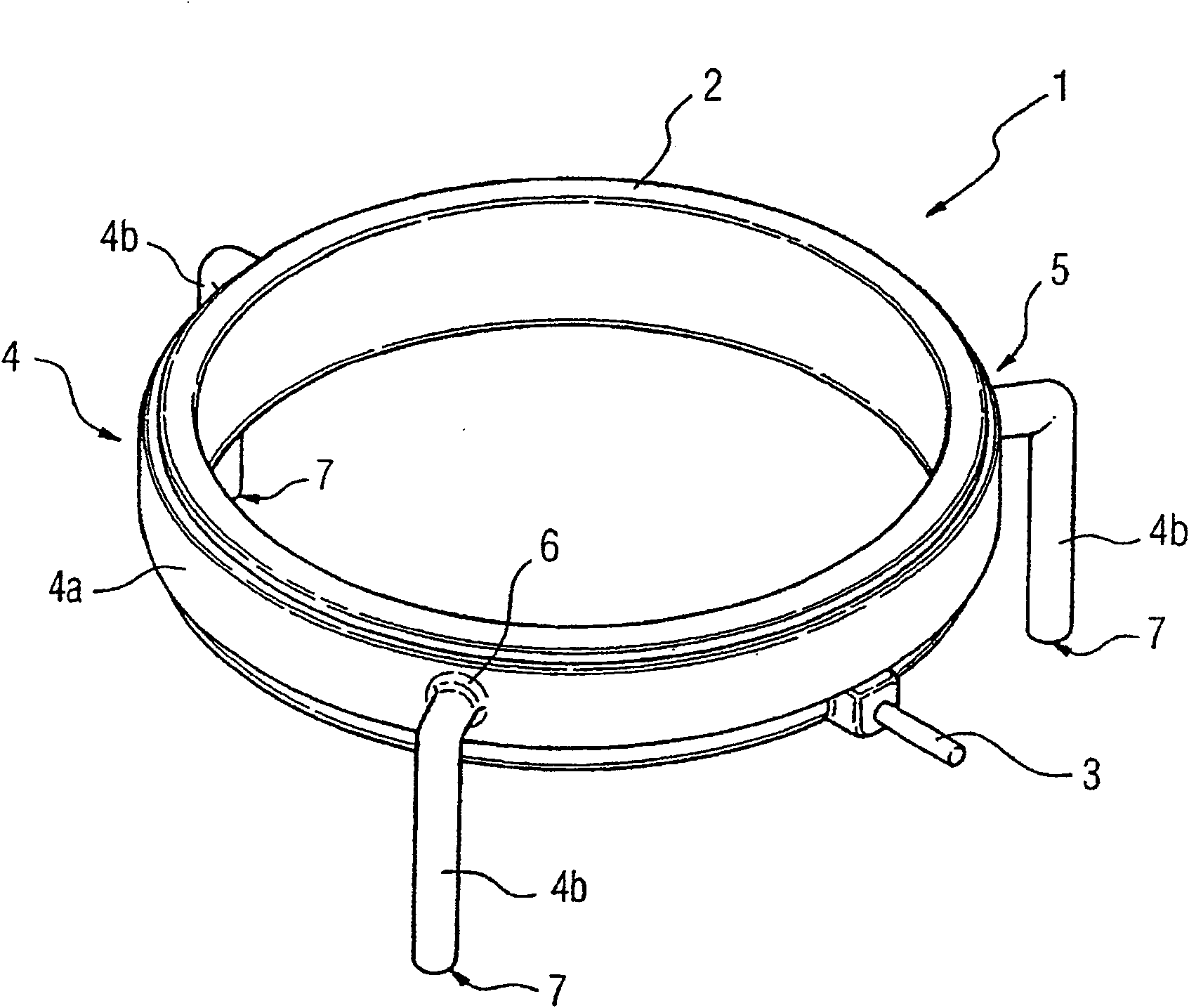

[0028] figure 1 An embodiment of a coupling electrode 1 according to the invention is shown in a perspective view. The coupling electrode 1 has a ring-shaped electrode part 2 and a connecting pin 3 connected to the ring-shaped electrode part as a connecting element. figure 1 In the exemplary embodiment shown, it is attached to the lower annular side of the electrode part 2 and protrudes outwards from there.

[0029] Furthermore, the coupling electrode 1 has a fastening device 4 which is fixedly connected to the electrode part 2 at its fastening side 5 . For this purpose, the fastening device 4 has a fastening ring 4 a clipped together with the electrode part 2 , on which three identically constructed L-shaped fastening legs 4 b are formed. The longer leg of the L-shaped fastening leg 4 b of the fastening device 4 is designed as a free end in order to form the parking device 7 . The three free ends 7 define a planar parking surface on which the coupling electrode 1 can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com