Equipment for manufacturing plastic bottle

A technology for manufacturing equipment and plastic bottles, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of unstable speed, low production efficiency, pinching, etc., and achieve compact production process, high work efficiency, and easy solution broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

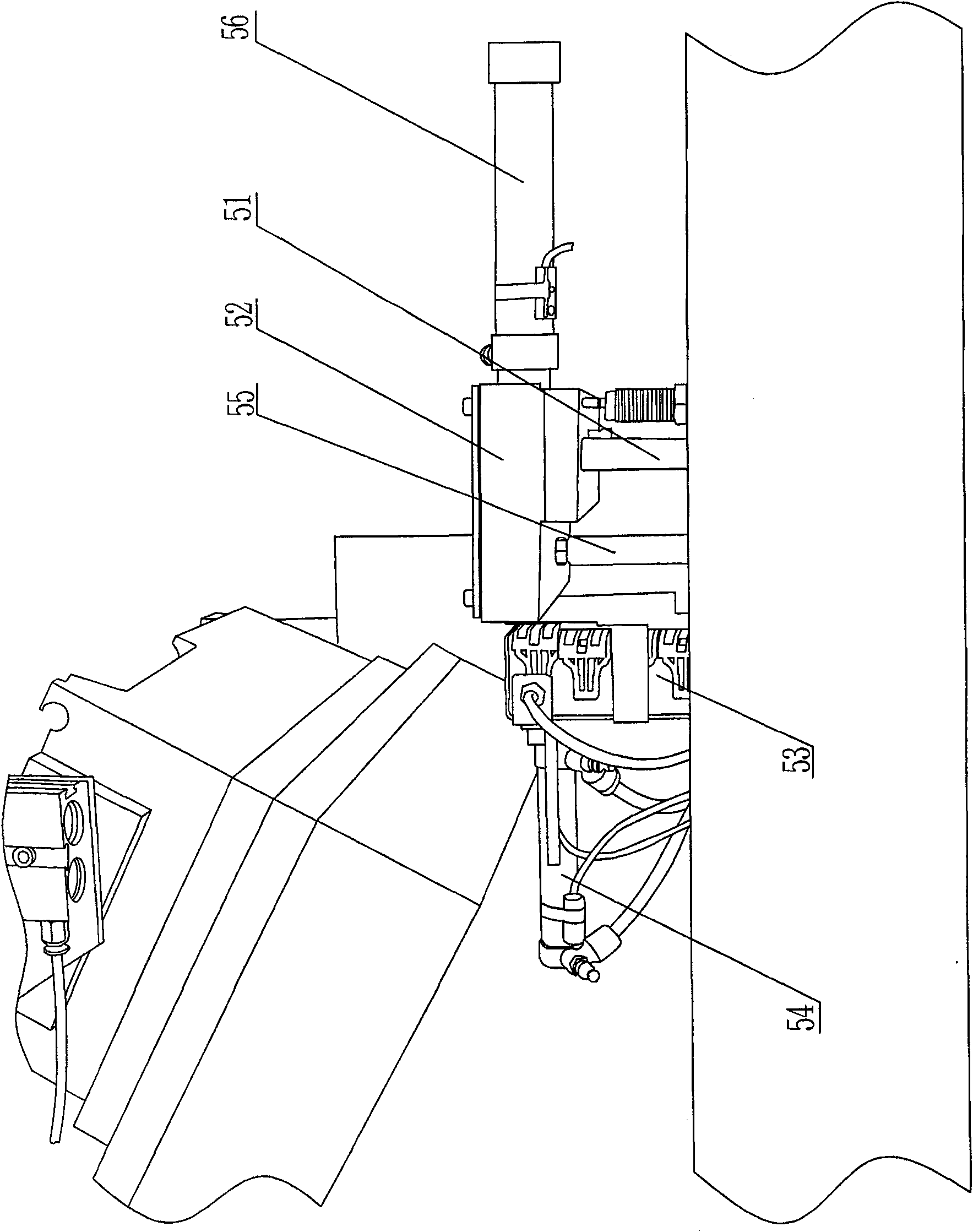

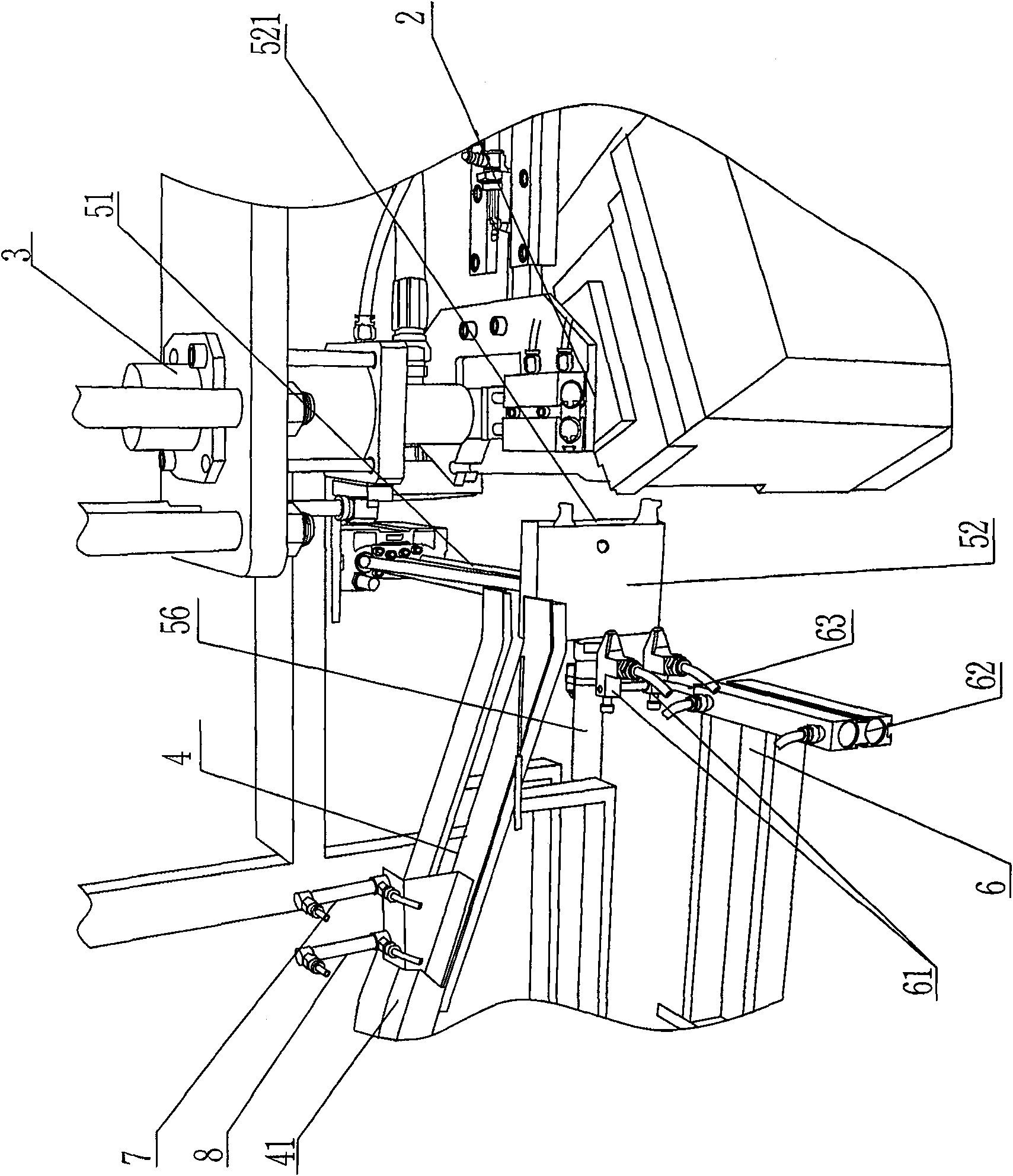

[0020] refer to Figure 1 to Figure 8 , a manufacturing method of a plastic bottle, first put the preform into a preheating device for preheating, the preheated preform is sent to the clamping mold through a conveying guide rail, and there is a blow molding device on the clamping mold, blowing The plastic molding device injects high-pressure gas into the preform to blow out the plastic bottle. There is a handle transfer device next to the conveying rail. The handle transfer device automatically sends the handle into the corresponding position on the edge of the mold cavity. During the manufacturing process, the bottle wall expands and bonds with the handle on the edge of the mold cavity.

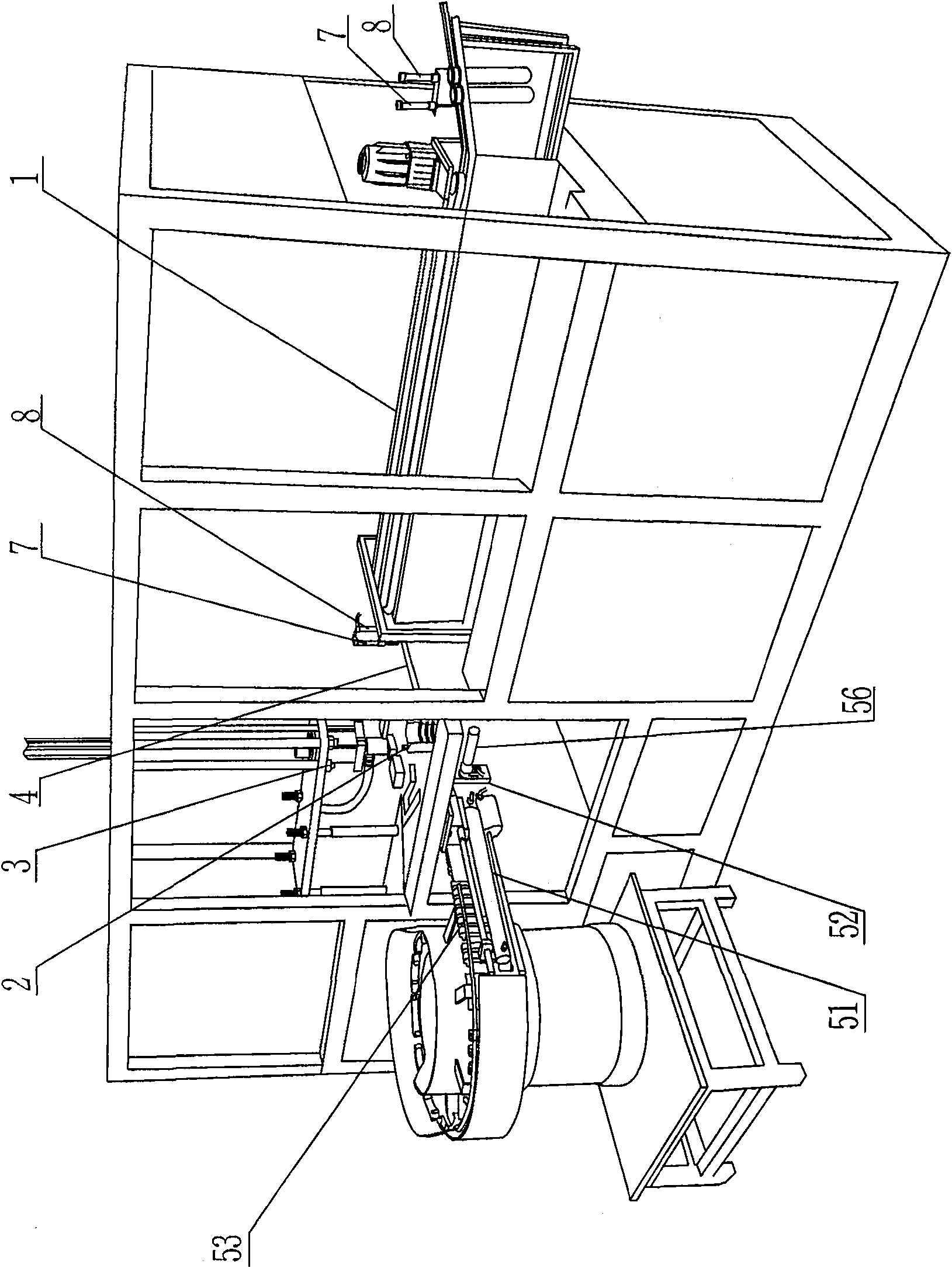

[0021] The plastic bottle manufacturing equipment in the above-mentioned plastic bottle manufacturing method includes a preheating device 1, a mold clamping device 2, a blow molding device 3, and a preform conveying guide rail set between the preheating device 1 and the mold clamping device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com