Button side face wire drawing device

A wire drawing and button technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as unstable quality and low efficiency, and achieve the effects of saving manpower, ensuring product quality, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

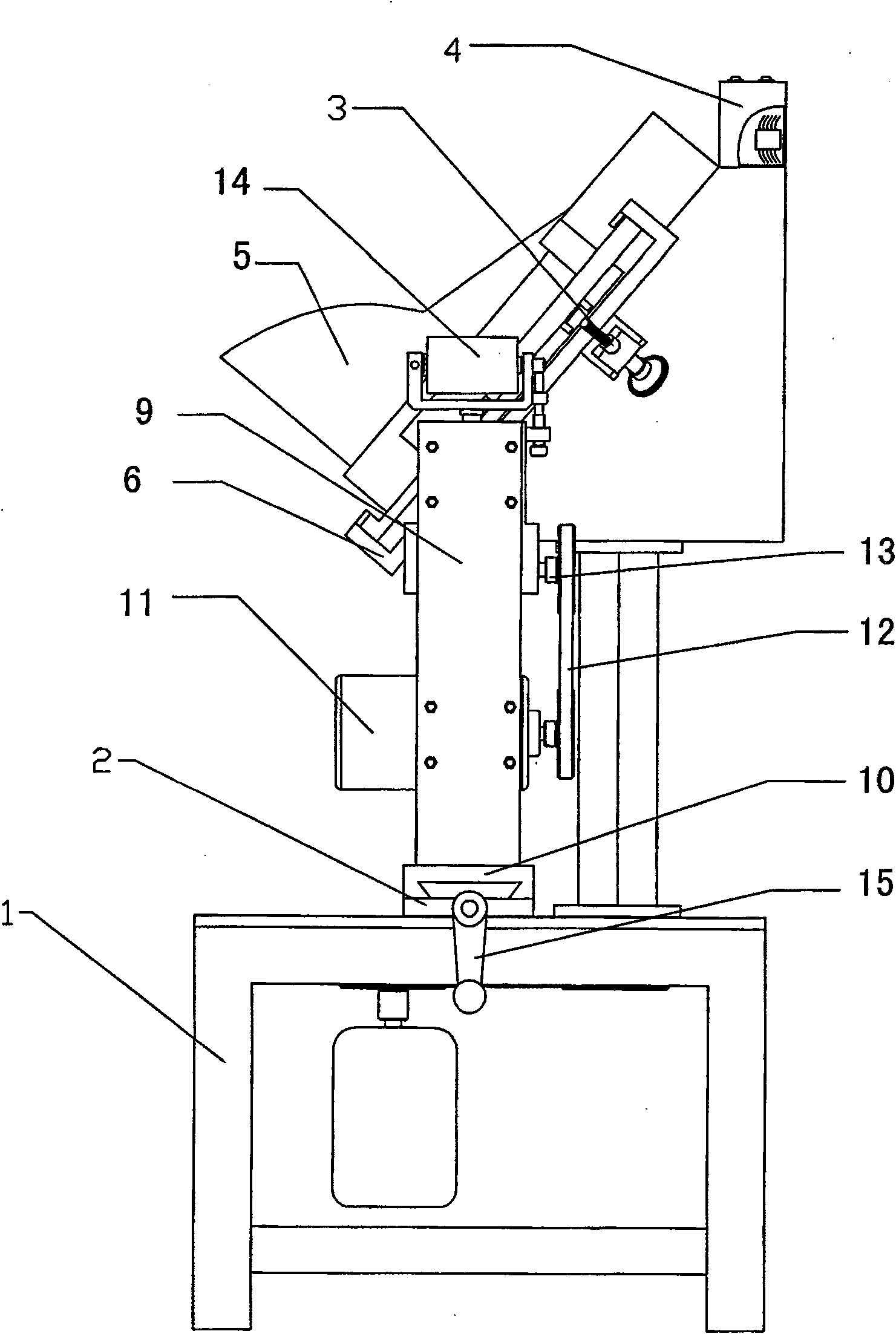

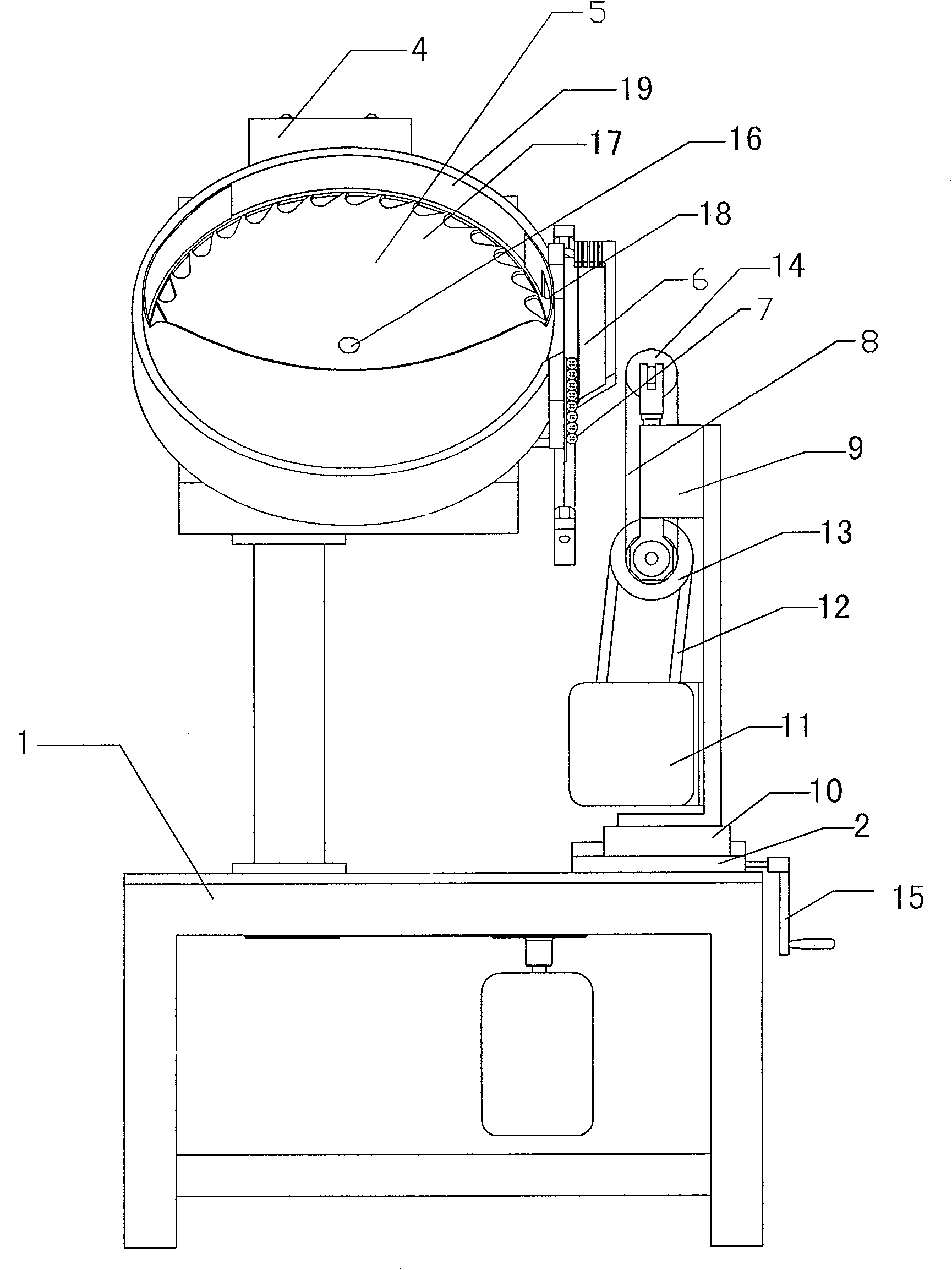

[0020] Please refer to the attached figure 1 And attached figure 2 , the main body of the present invention is a frame 1, and the frame 1 mainly supports the present invention, the bottom of the frame 1 is a base, and the top is equipped with a feeding tray 5 through a support column, and the feeding tray 5 includes a trough 19 and a feeding ratchet 17, and The main body of the groove 19 is barrel-shaped, and it is inclined. The inclination angle is not limited, and it is greater than 0 degrees and less than 90 degrees. 17 slide, in the present embodiment, the preferred angle of inclination given is 45 degrees. In this embodiment, the main body of the trough 19 is in the shape of a barrel, and a circular feeding ratchet 17 is installed at the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap