Method for making wearing articles

A technology for articles and clothing, which is applied in medical science, clothing, underwear, etc., can solve problems such as asymmetrical conveying directions, troublesome conveying of semi-finished products and finished products, and achieve the effects of expanding degrees of freedom, reducing costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

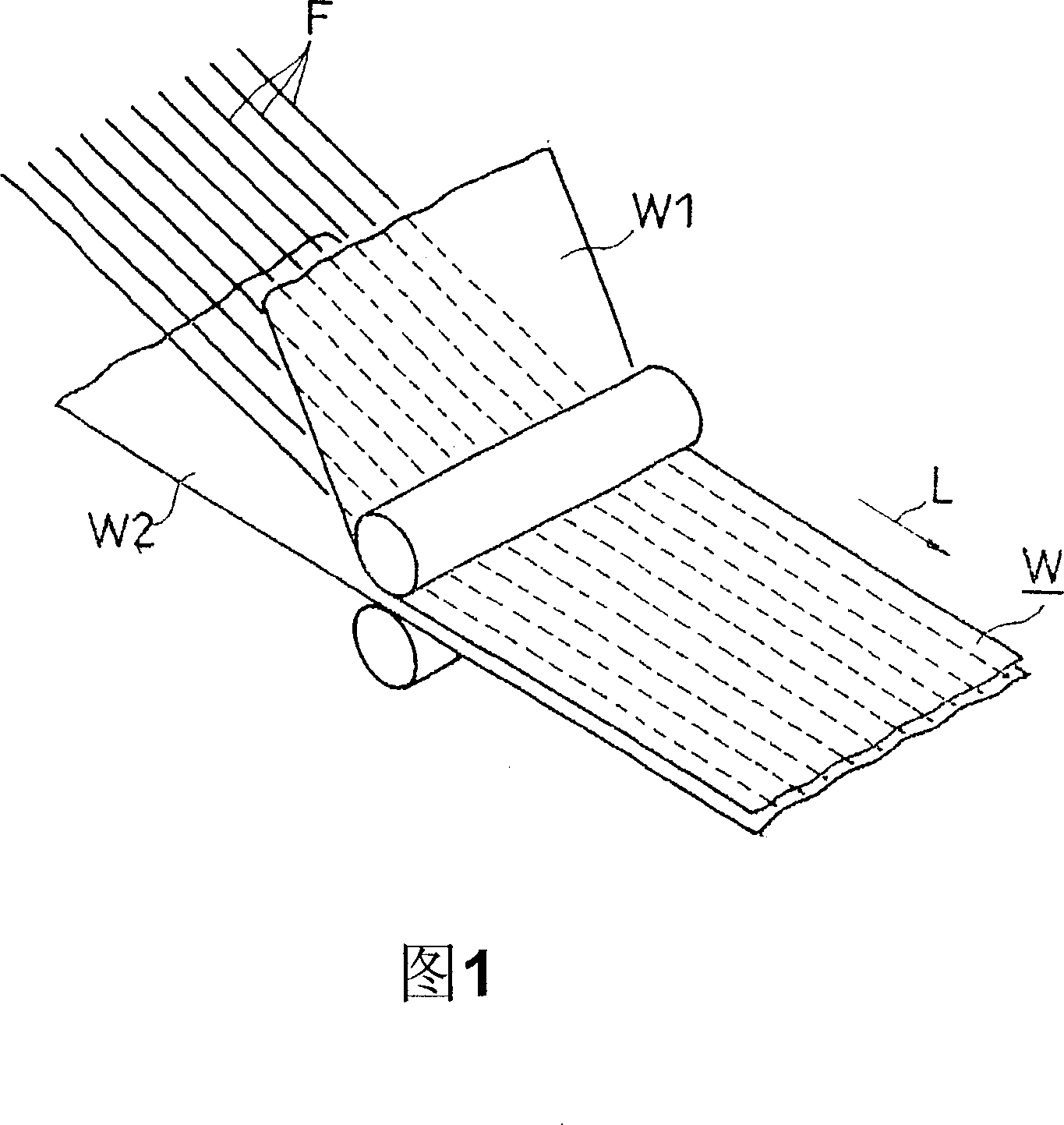

[0022] Next, Embodiment 1 of the present invention will be described with reference to the drawings.

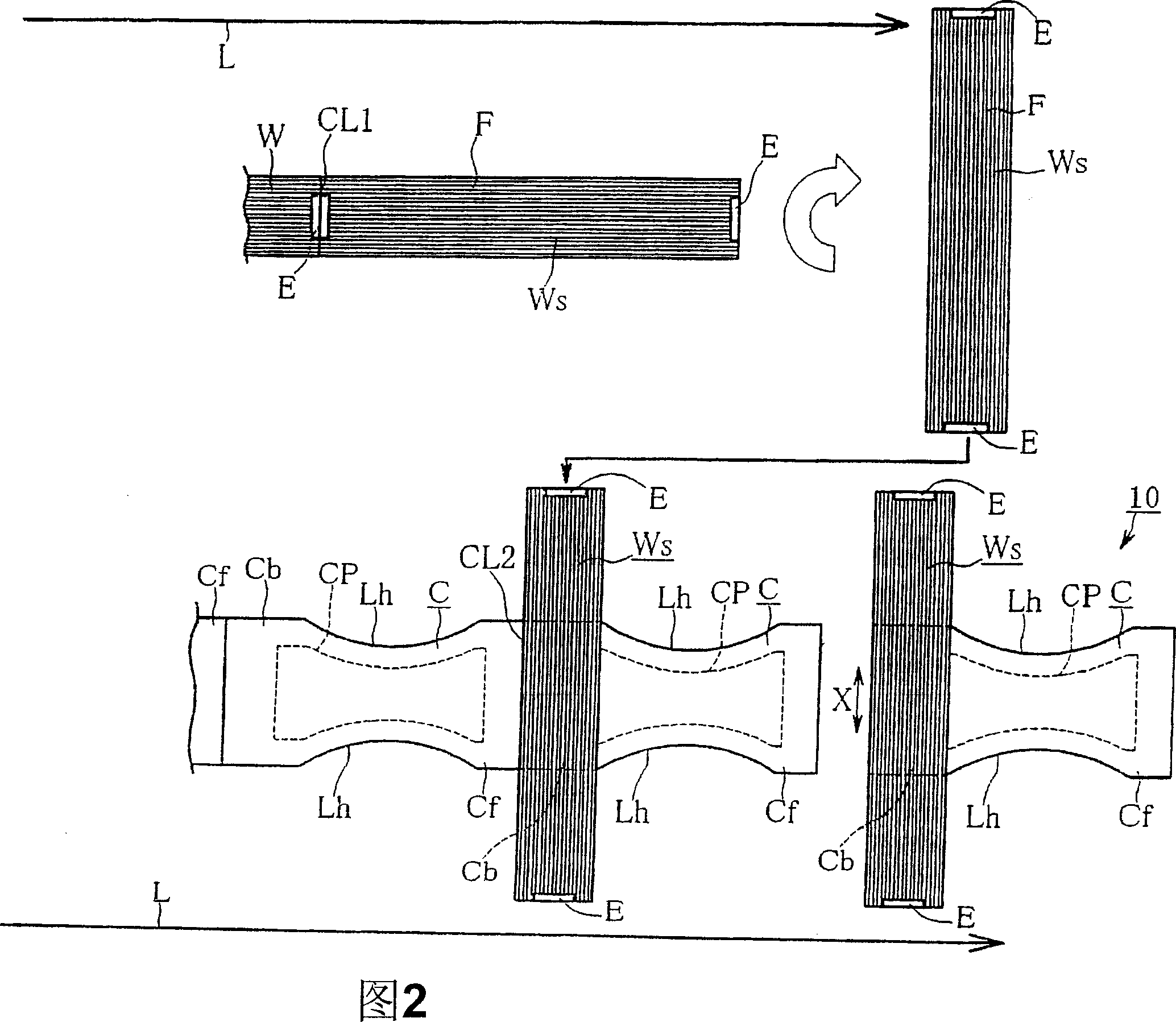

[0023] 1 and 2 show Example 1.

[0024] Diaper (wearing article) 10:

[0025] First, an example of a wearing article manufactured by the present invention will be described with reference to FIG. 2 .

[0026] As shown in the lower right end of FIG. 2 , a diaper (an example of a wearing article) 10 is formed in a T shape by overlapping the waist member Ws on the diaper main body C. As shown in FIG.

[0027] In the waist part Ws, along the waist direction X, for example, an elastic member F made of a plurality of string rubber or flat rubber is disposed.

[0028] The diaper main body C is integrally formed with a front part Cf covering the wearer's abdominal side, a rear part Cb covering the wearer's back side, and a crotch part CP covering the wearer's crotch. The said waist part Ws is overlapped with the rear part Cb of the diaper main body C, and is connected.

[0029] L...

Embodiment 2

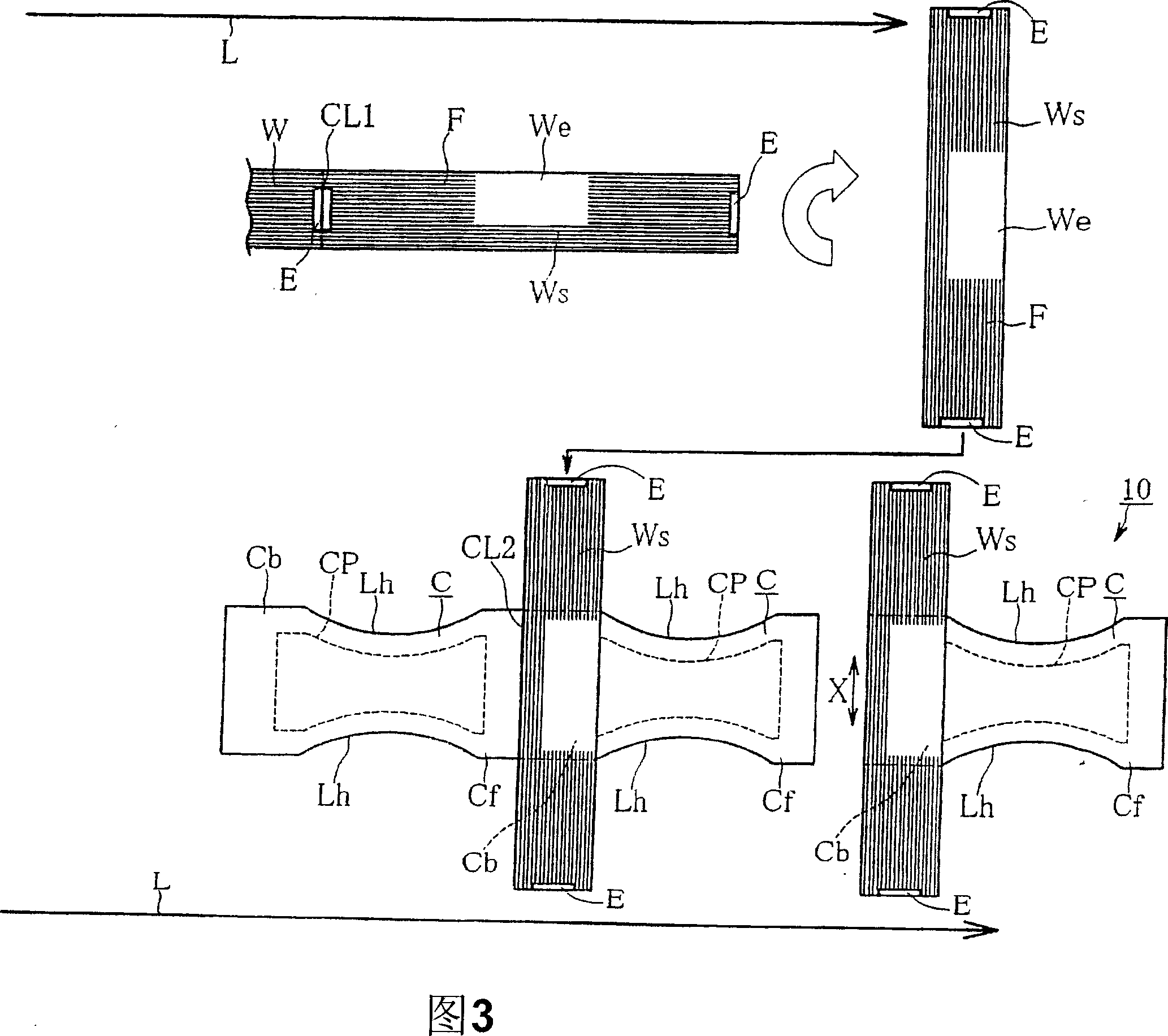

[0047] Fig. 6 shows a second embodiment.

[0048] The elastic sheet W2 shown in FIG. 6 is made of, for example, a highly stretchable resin sheet at least in the width direction, and is conveyed in the longitudinal direction L. As shown in FIG. Surface fasteners E are arranged at both end portions along the flow direction L of the elastic sheet W2. The front end portion of the elastic sheet W2 is cut along the first cutting line CL1 to produce the waist part Ws. Surface fasteners E may be arranged at both ends of the waist part Ws to be produced.

[0049] The above-cut waist member Ws is stretched in the waist direction X which is the width direction substantially perpendicular to the length direction L. The said waist member Ws is arrange|positioned on the rear part Cb of the diaper main body C in the state stretched, and it cuts along the 2nd cutting line CL2, and produces the diaper 10.

[0050]The other structures are the same as those in Embodiment 1, and the same refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com