Sheet sorting method and apparatus

A paper and equipment technology, applied in the field of paper picking and equipment, can solve different problems, achieve the effect of reducing the number, eliminating changes, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

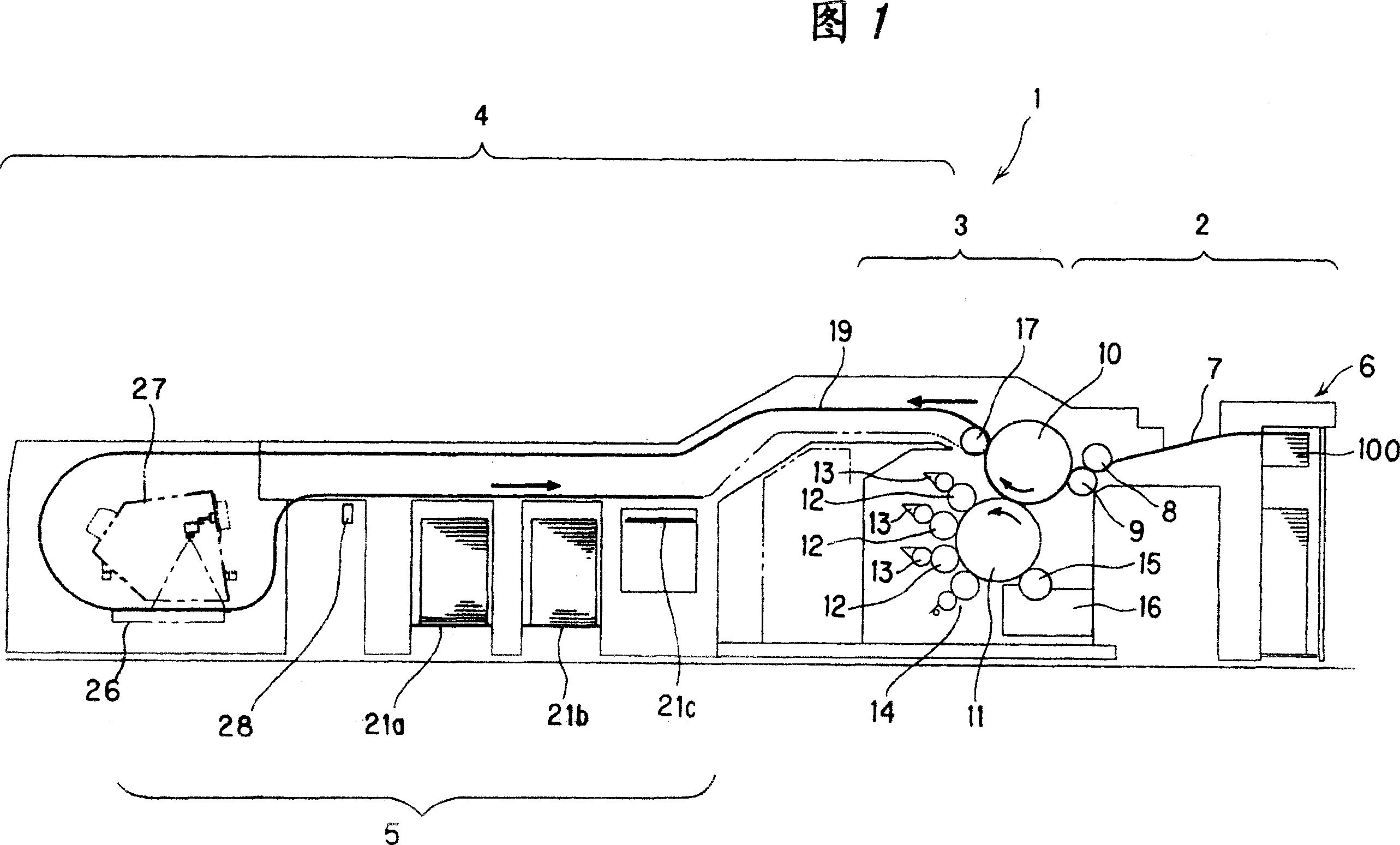

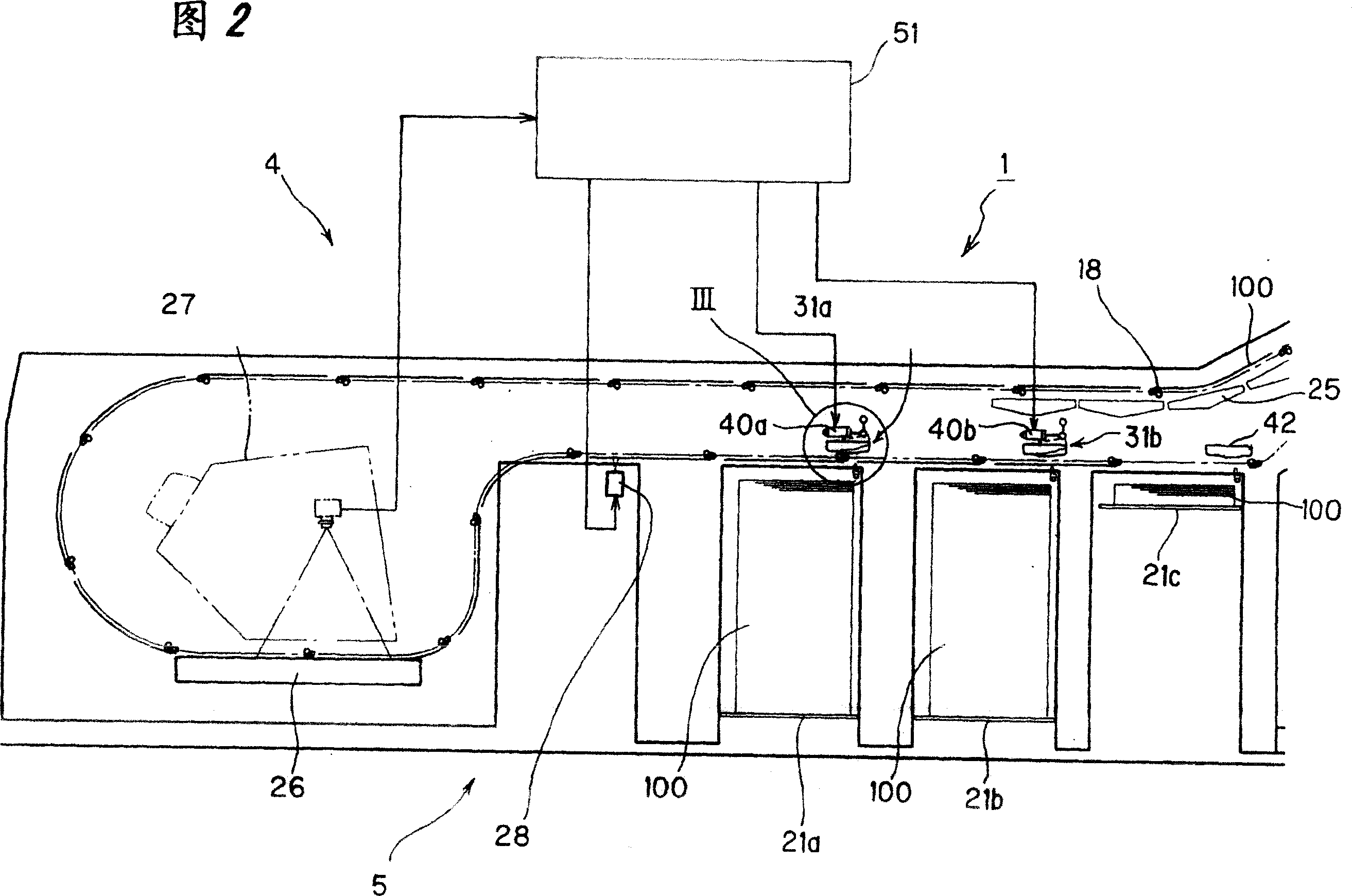

[0077] As shown in FIG. 1 , a printing machine 1 is formed of a feeder 2 , a printing unit 3 located behind it, and a transfer unit 4 located behind the printing unit 3 . The transfer unit 4 is equipped with a picking device 5 which implements a picking method according to one embodiment of the invention and which itself also corresponds to an embodiment of the invention.

[0078] The feeder 2 is equipped with a paper feeding device 6 for feeding paper sheets 100, which are sheets stacked on each other, one by one. Each sheet of paper 100 fed by the paper feeding device 6 is conveyed to the conveying rollers 8 and 9 via the feeder plate 7 and a swing arm pivot pre-gripper not shown. Then, each sheet 100 is conveyed from the conveying roller 9 to the platen roller 10 .

[0079] In the printing unit 3 , an intaglio roll 11 adjoins an embossing roll 10 . Three Chablon rollers 12 adjoin the intaglio roller 11 . The Chablon roller 12 has an inking unit 13 attached thereto. Thus...

Embodiment 2

[0233] FIG. 21 shows an outline of a sorting device according to Embodiment 2. This picking device is also integrated into the unloading unit of the printing press.

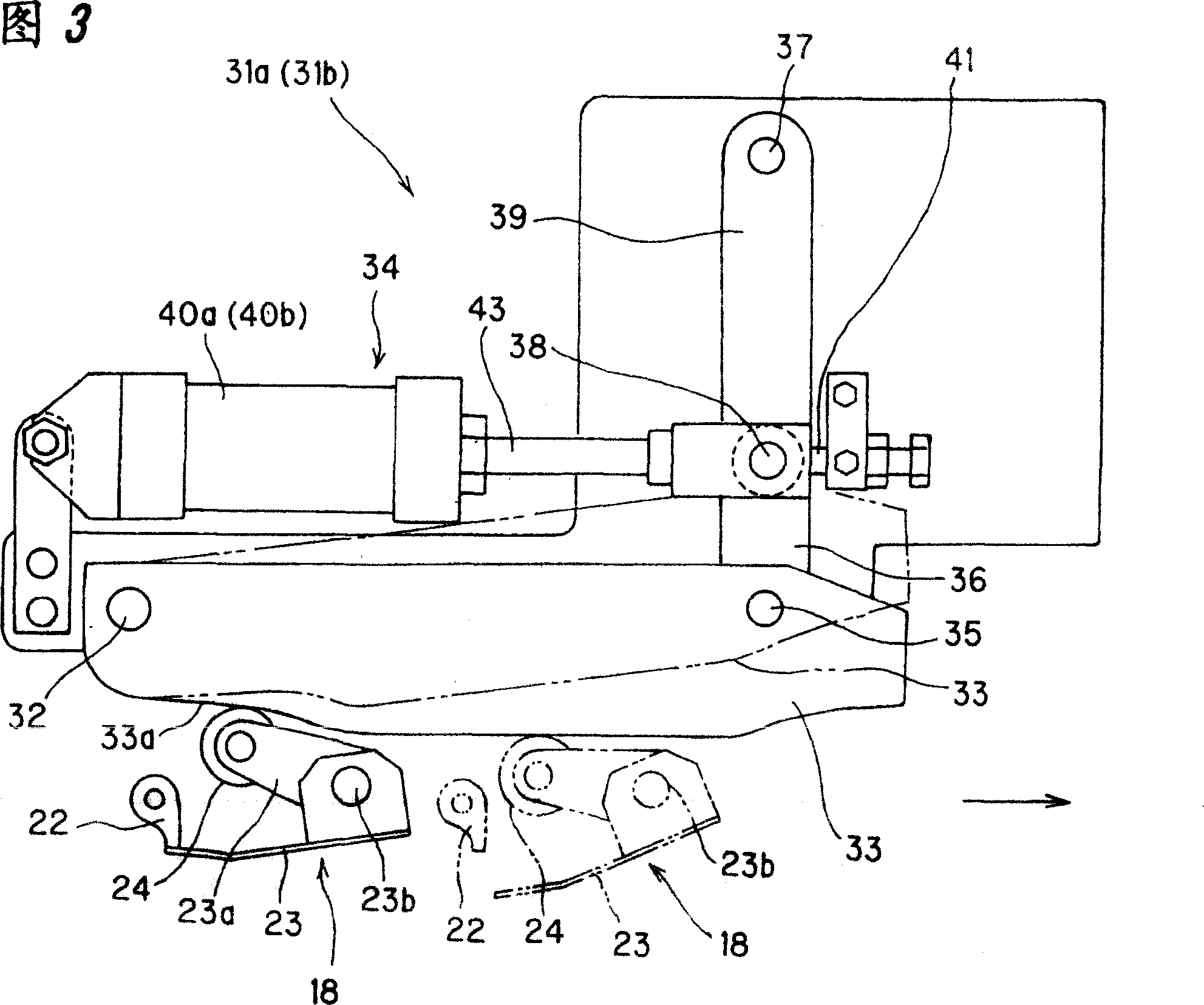

[0234] The structure of the feeder and the printing unit in the printing machine is the same as that of the conveying unit and the printing unit shown in FIGS. 1 and 2 . In their transfer units, seven stacked plates 61a, 61b, 61c, 61d, 61e, 61f, 61g and 61h are provided. In the portion on each of the stack plates 61a to 61g, the same delivery cam device as shown in FIG. 3 is provided. In a portion above the stack plate 61h, a fixed delivery cam is provided.

[0235] The first two stacking boards 61a and 61b are stacking boards on which good-quality sheets are unloaded. That is, the first two stacking plates 61a and 61b are positions for unloading good products, respectively, and the conveying cams located above the respective plates are good product paper unloading means.

[0236] The stacking boards 61c to 61g...

Embodiment 3

[0241] 22 and 23 show examples of grouping different from the above-mentioned embodiment.

[0242] The case of printing patterns of 5 columns and 8 rows on each sheet 100 is the same as in the previous embodiment. This grouping is done by dividing the patterns into groups, each group comprising 10 small cut paper sheet printed products 101 . Groups a, b, c, d and e are formed such that each group extends into two adjacent columns (the boundaries between groups are indicated by the thick black lines in Figures 22 and 23).

[0243] In addition, in the case of grouping the patterns in this way, each sheet of which all the patterns have no defects is sorted out as a good product sheet, and each sheet of paper having a defective pattern in only one of the groups a to d is sorted out. Picked as a single set of defective sheets, sheets each having a defective pattern in a plurality of sets a to d are picked as multiple sets of defective sheets.

[0244] Even if there is a defective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com