Liquid crystal display element

A technology of liquid crystal display elements and liquid crystal layers, applied in static indicators, optics, instruments, etc., can solve problems such as poor display and achieve excellent visual recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

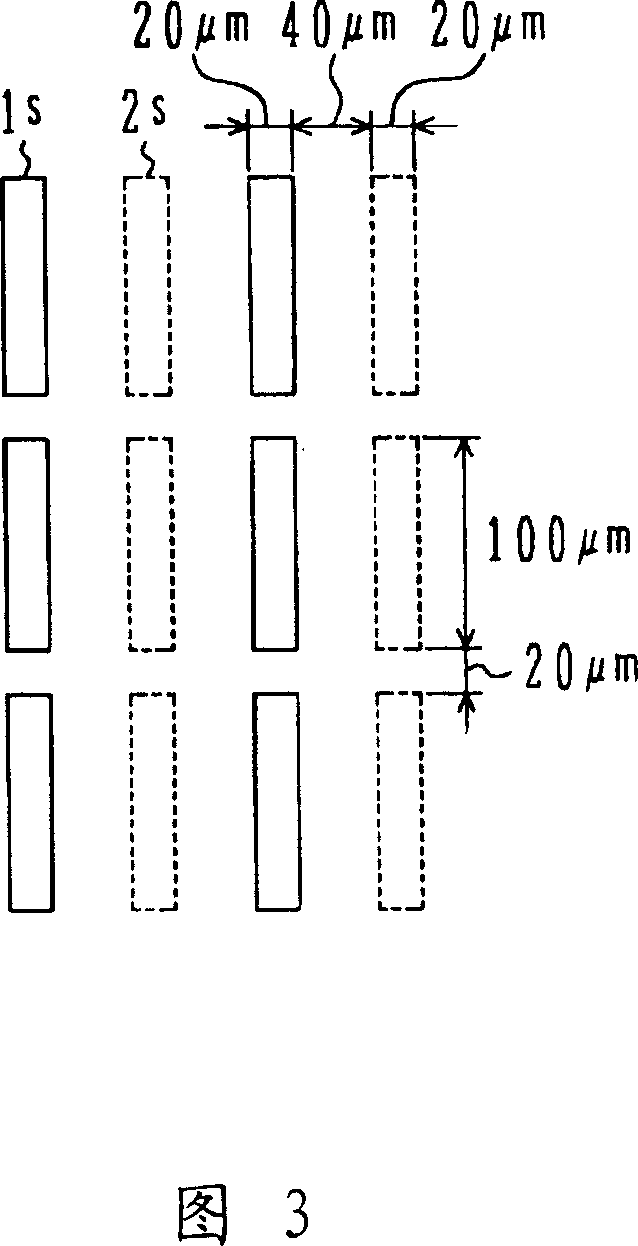

[0081] FIG. 8 shows an example of a two-region TN-LCD having a segment structure. The structure of the TN-LCD shown in FIG. 8 is that upper segment electrodes 6 and lower common electrodes 7 representing numbers "1" and "2" sandwich liquid crystal as a pair of electrodes. In this example, the conduction range of the segment electrode 6 is narrowed, and the conduction range of the common electrode 7 is widened.

[0082] The segment electrode 6 and the common electrode 7 are provided with rectangular slits 6 s and 7 s with a part removed. The slits 6s provided on the segment electrodes and the slits 7s provided on the common electrode are arranged alternately in the short direction of the slits. In addition, the number of divisions per unit length of the slit provided on one electrode is different from that of the slit provided on the other electrode. Here, the number of divisions refers to the number of separation positions in the longitudinal direction of the slit, and when ...

no. 2 example

[0098] A vertical alignment type LCD of a second embodiment will be described. Briefly, the two-region vertical alignment type LCD of the second embodiment is an LCD of the same structure and material as those of the second comparative example, and its slit pattern is the same as that of the first embodiment.

[0099] When a voltage was applied to the cell to display the liquid crystal cell, no display unevenness was observed even when the liquid crystal cell was viewed from an oblique direction. Furthermore, even after 1000 hours had elapsed after the cell was continuously energized in an atmosphere of 85° C., display failure did not occur.

no. 3 example

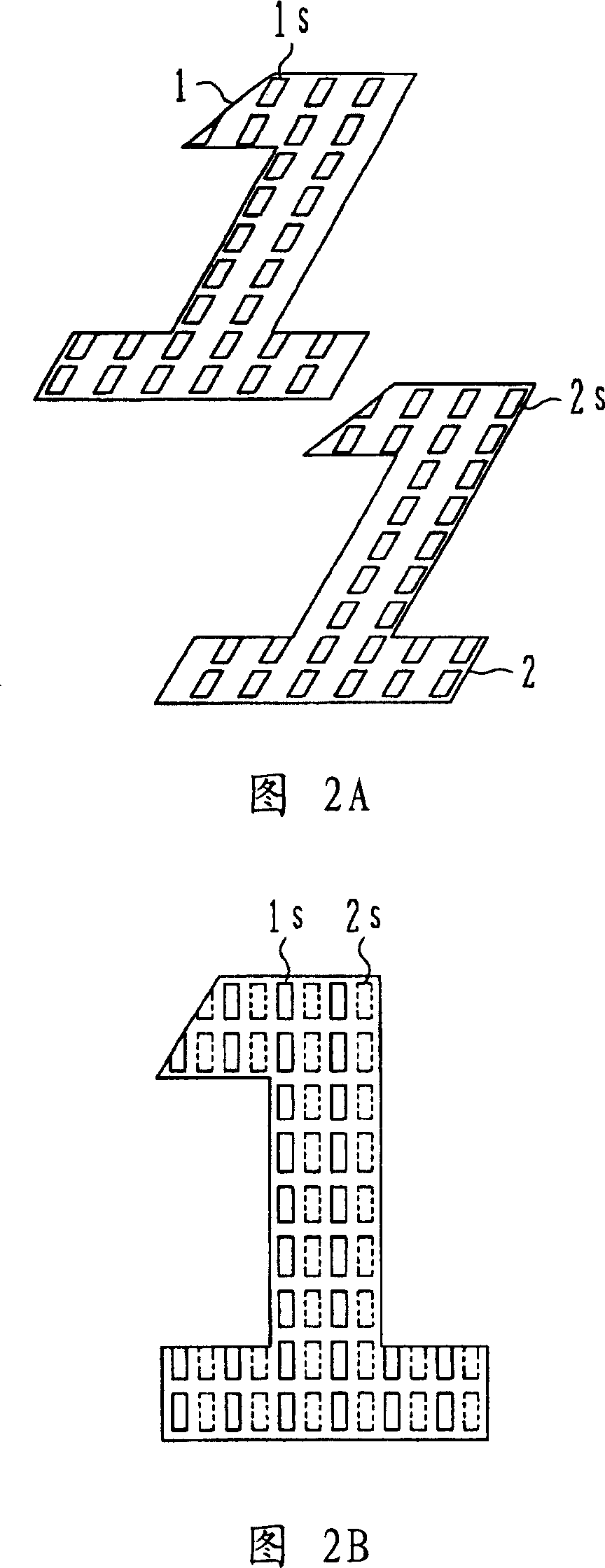

[0101] The case of a simple matrix type two-region TN-LCD and a two-region vertical alignment type LCD will be described with reference to FIG. 10 . Fig. 10 is a plan view of a simple matrix liquid crystal display element of the present invention.

[0102] Similar to the segment display, the liquid crystal cell used in the third embodiment, as shown in FIG. 10 , has a structure in which the upper segment electrode 15 and the lower common electrode 16 serve as a pair of electrodes sandwiching the liquid crystal. The segment electrodes 15 and the common electrode 16 are provided with rectangular slits 15 s and 16 s with a part removed. The slits 15s provided on the segment electrodes 15 and the slits 16s provided on the common electrode 16 are alternately arranged in the short direction of the slits. Furthermore, the number of divisions per unit length of the slit provided on one electrode is different from that of the slit provided on the other electrode, and the slit with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com