Detergent composition

A technology of composition and cleaning agent, applied in the field of cleaning agent, can solve the problems of reduced operating efficiency, pipe blockage, pigment blockage, etc., and achieve the effect of less burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

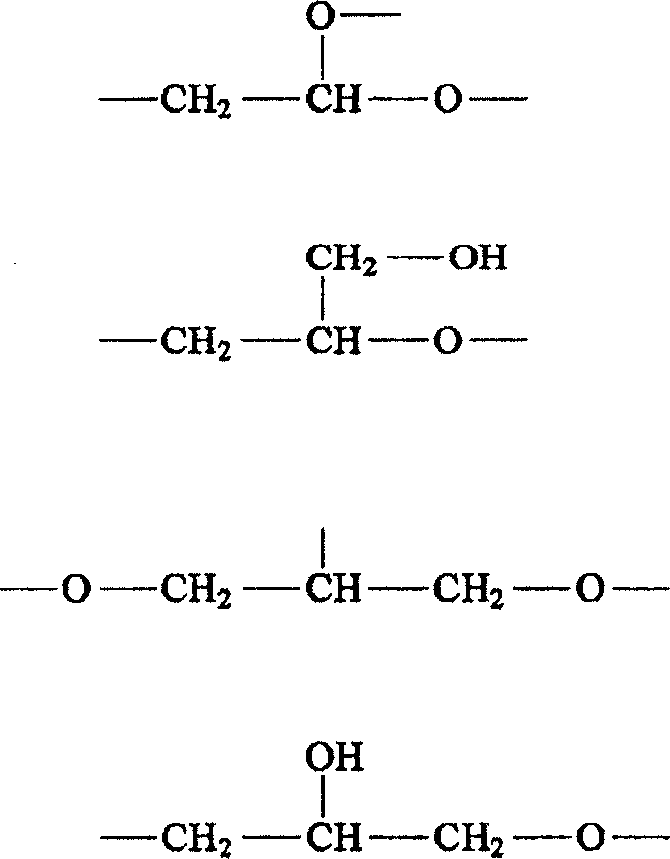

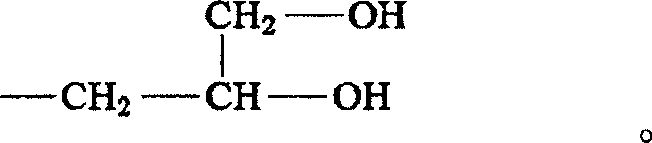

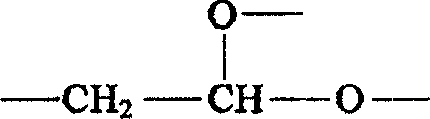

Method used

Image

Examples

no. 1 approach

[0044] [Composition of cleaning agent]

[0045] The cleaning agent according to the first embodiment of the present invention contains at least one solvent and a Si-based surfactant capable of dissolving and removing the pigment-dispersed composition adhering to a substrate such as a semiconductor substrate. Also, the above-mentioned solvents contain aromatic hydrocarbons.

[0046] The solvent contained in the cleaning agent according to the first embodiment of the present invention may be composed of only one solvent, but in order to satisfy various characteristics such as cleaning performance, drying performance, and prevention of sedimentation of the pigment to be cleaned, it is used Mixed solvents of various solvents allow easy design of various cleaning solutions with well-balanced properties. From this point of view, it is preferable to use mixed solvents.

[0047] [solvent]

[0048] The solvent contained in the cleaning agent according to the first embodiment of the p...

no. 2 approach

[0067] [Composition of cleaning agent]

[0068] The cleaning agent according to the second aspect of the present invention contains at least one solvent and a surfactant capable of dissolving and removing the pigment-dispersed composition adhering to a substrate such as a semiconductor substrate.

[0069] In addition, the cleaning agent according to the second embodiment of the present invention is preferably composed of a solvent having a boiling point of 60° C. to 300° C. under normal pressure.

[0070] The solvent contained in the cleaning agent according to the second embodiment of the present invention may be composed of only one kind of solvent, but in order to satisfy various characteristics such as cleaning performance, drying performance, and prevention of sedimentation of the pigment to be cleaned, a variety of solvents are used. A mixed solvent of these solvents can be used to easily design various cleaning solutions with well-balanced properties. From this point of...

Embodiment 1

[0116] 20 parts by mass of PGME, 60 parts by mass of PGMEA, and 20 parts by mass of Solvesso 100 (trade name; manufactured by Exxon Chemical Co.) were mixed, and 0.005 parts by mass of Additol XL-121 (trade name ; Solutia Co., Ltd.), and stirred and mixed to prepare the cleaning agent composition (A).

[0117] When the cleaning agent composition (A) was filled in the glass tube delivered through CFPR GH-1004 in liquid form, no aggregation and sedimentation of the pigment was observed.

[0118] When the cleaning agent composition (A) was filled in the glass tube conveyed through CFPR BK-5005SL in liquid form, aggregation and sedimentation of the pigment were not observed.

[0119] When the cleaning agent composition (A) was filled in the glass tube through which the inkjet ink for color filters was conveyed in liquid form, aggregation and sedimentation of the pigment were not observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com