Cast-in-situ reinforced concrete hollow slab and construction method thereof

The technology of a hollow floor slab and a construction method, which is applied to the field of reinforced concrete hollow core slabs, can solve the problems of low work efficiency, high cost, displacement of the inner mold position, etc., and achieves the effect of saving construction cost and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

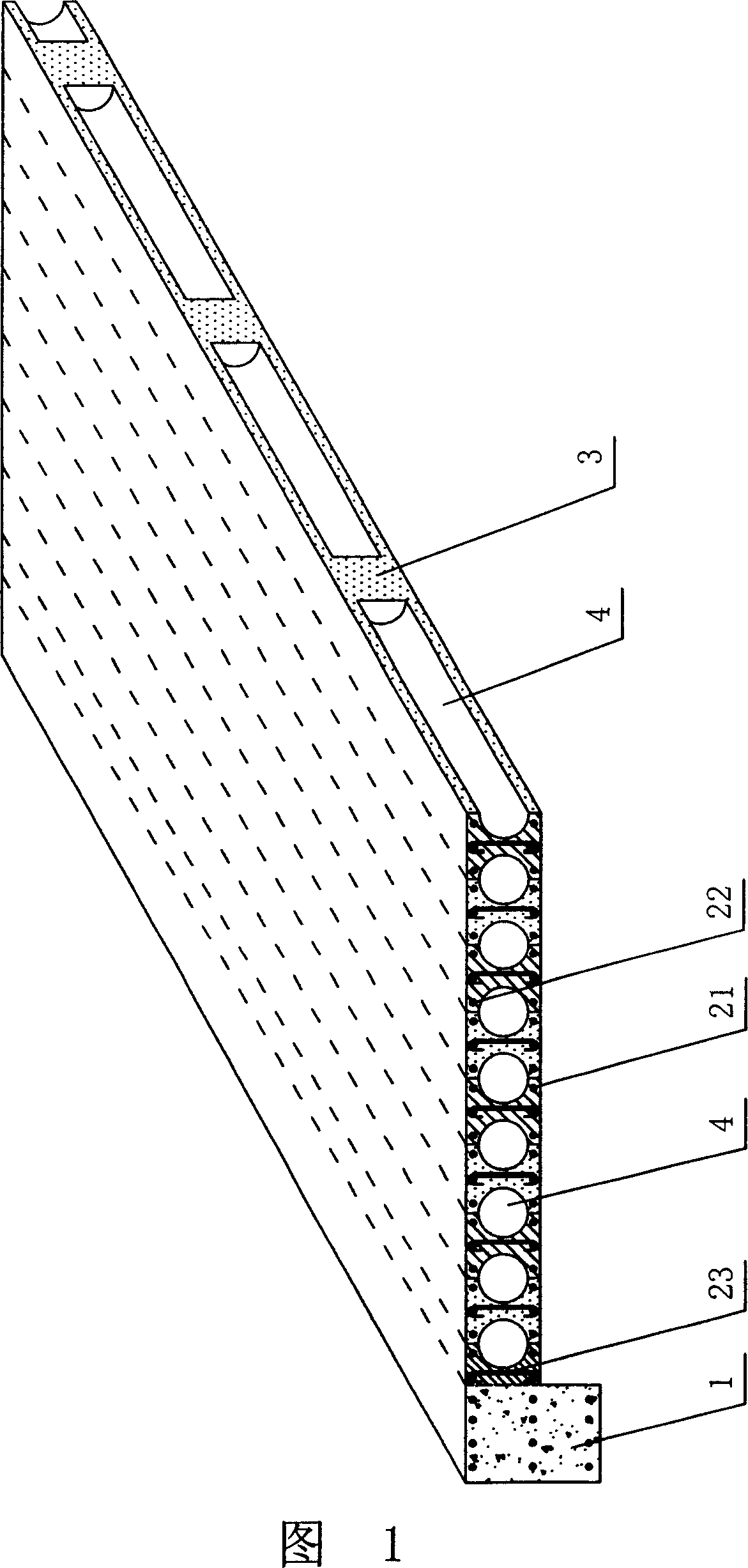

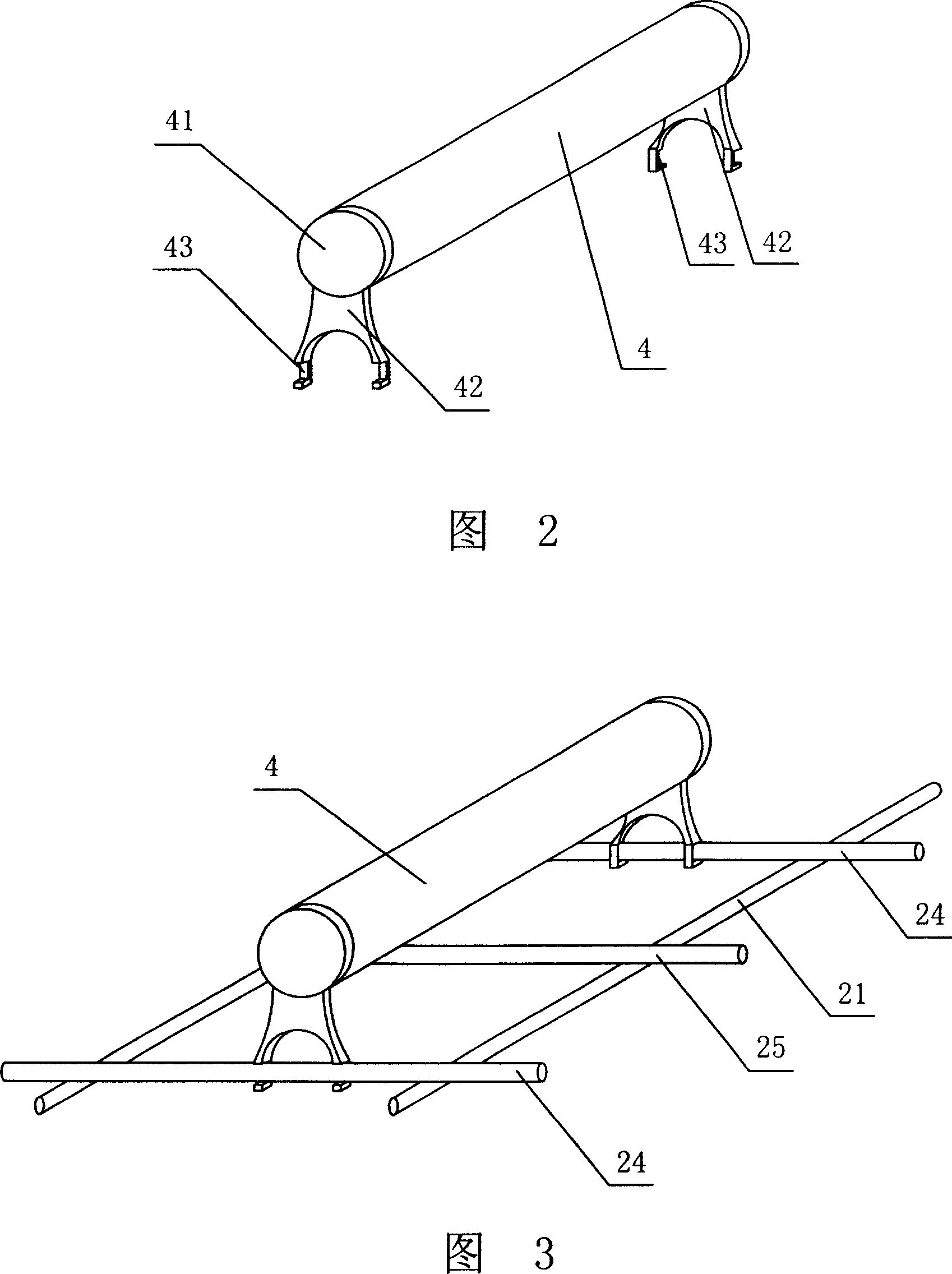

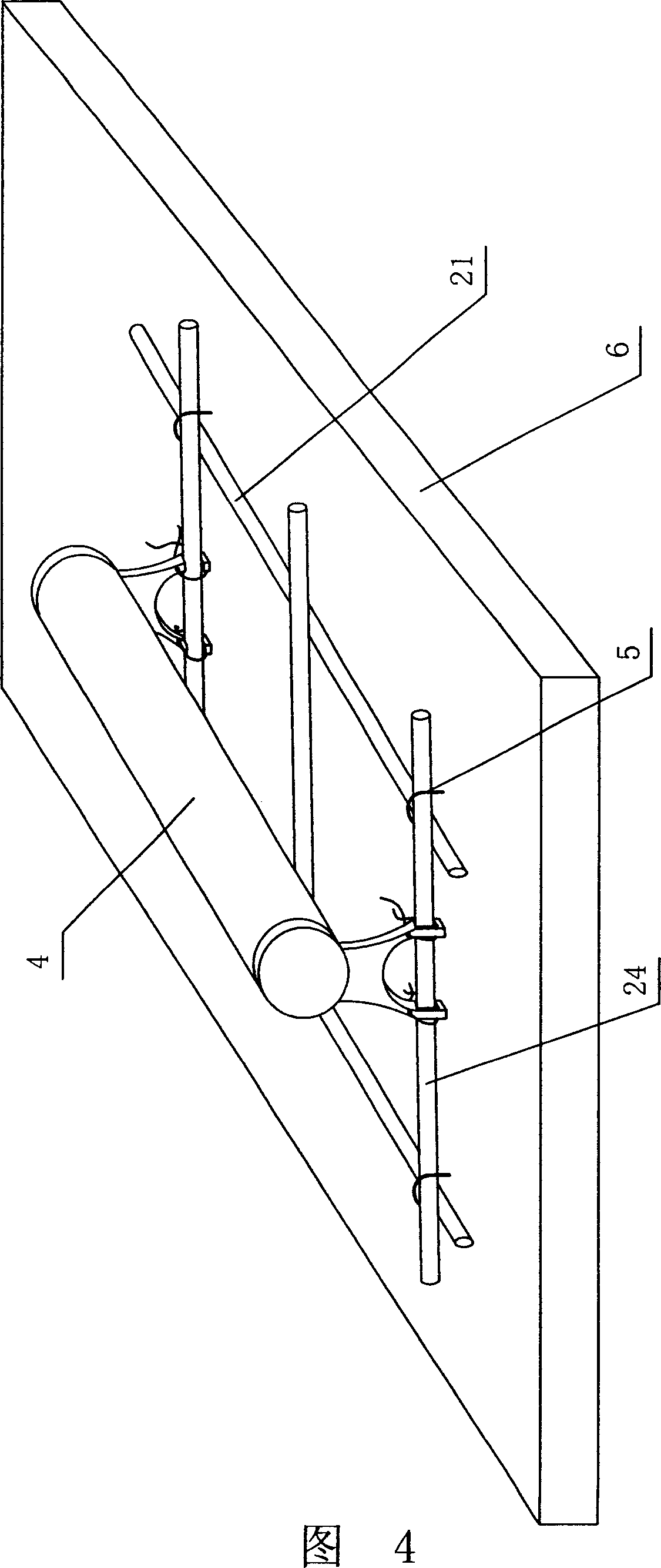

[0027] As shown in Figures 1 and 2, the present invention is a cast-in-place reinforced concrete hollow floor slab, which is composed of beams between wall columns 1, steel bars 2, cast-in-place concrete 3, and a hollow inner mold 4. The side of the hollow floor slab is provided with a beam 1 between the wall and the column; the steel bar 2 includes a slab bottom steel bar 21, a slab top steel bar 22, and a connecting steel bar 23, and the connecting steel bar 23 connects the slab bottom and the slab top steel bar; the two ends of the hollow inner mold 4 have end caps 41, and has a mounting bracket 42, the mounting bracket 42 is integrated with the end cover 41, the lower end of the mounting bracket 42 is provided with a draw-in groove 43, and the opening of the draw-in groove 43 can be in any direction. In this embodiment, the hollow inner mold 4 and The connecting steel bars 23 are arranged alternately and arranged in sections, and the openings of the slots 43 are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com