Hatchback door structure for vehicles

A rear and door technology, which is applied in the field of lift-up rear door structure, can solve the problems such as the increase of vehicle fuel costs and the ease of opening and closing, and achieve the effects of improving rear vision, improving rigidity, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

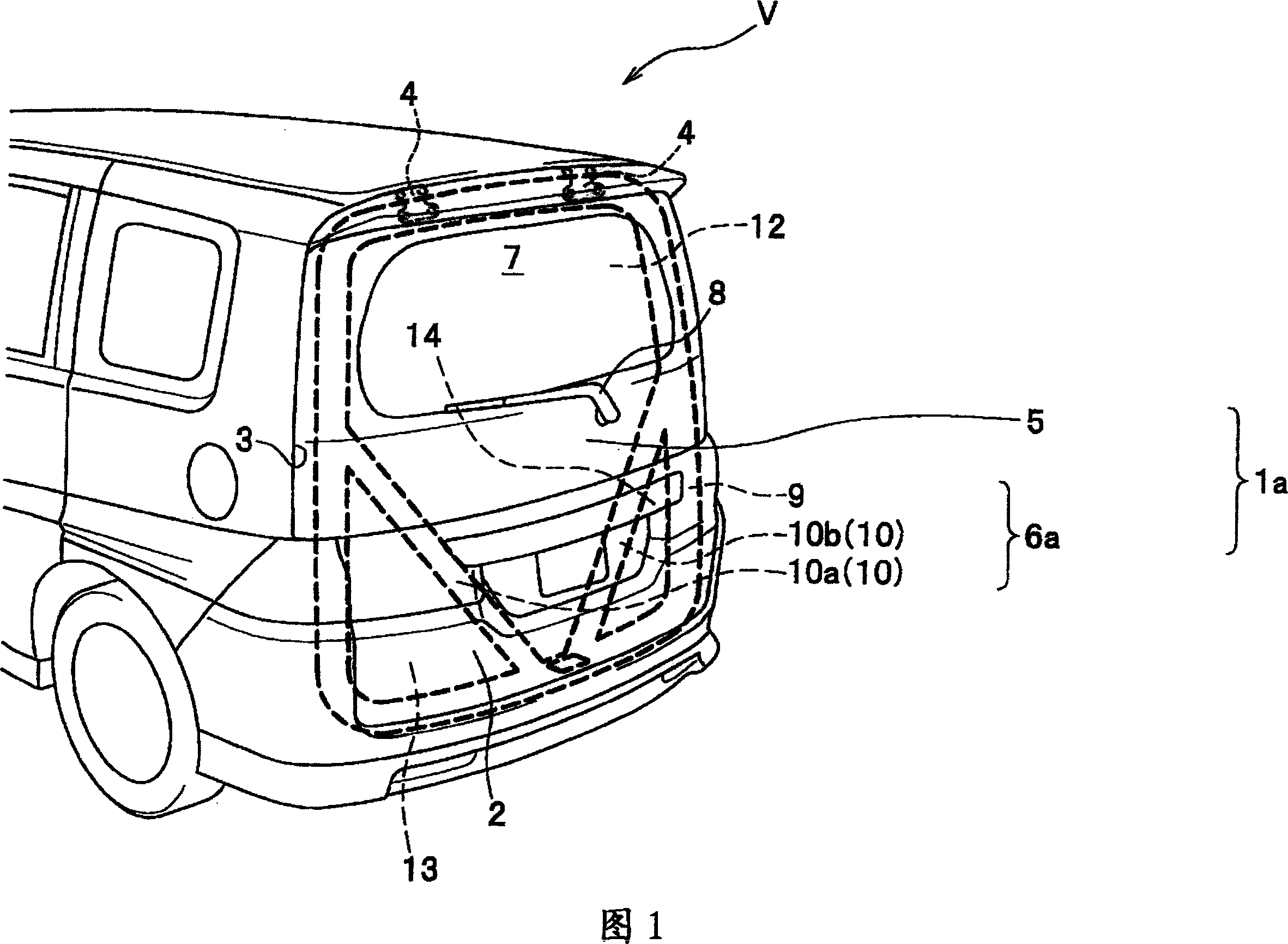

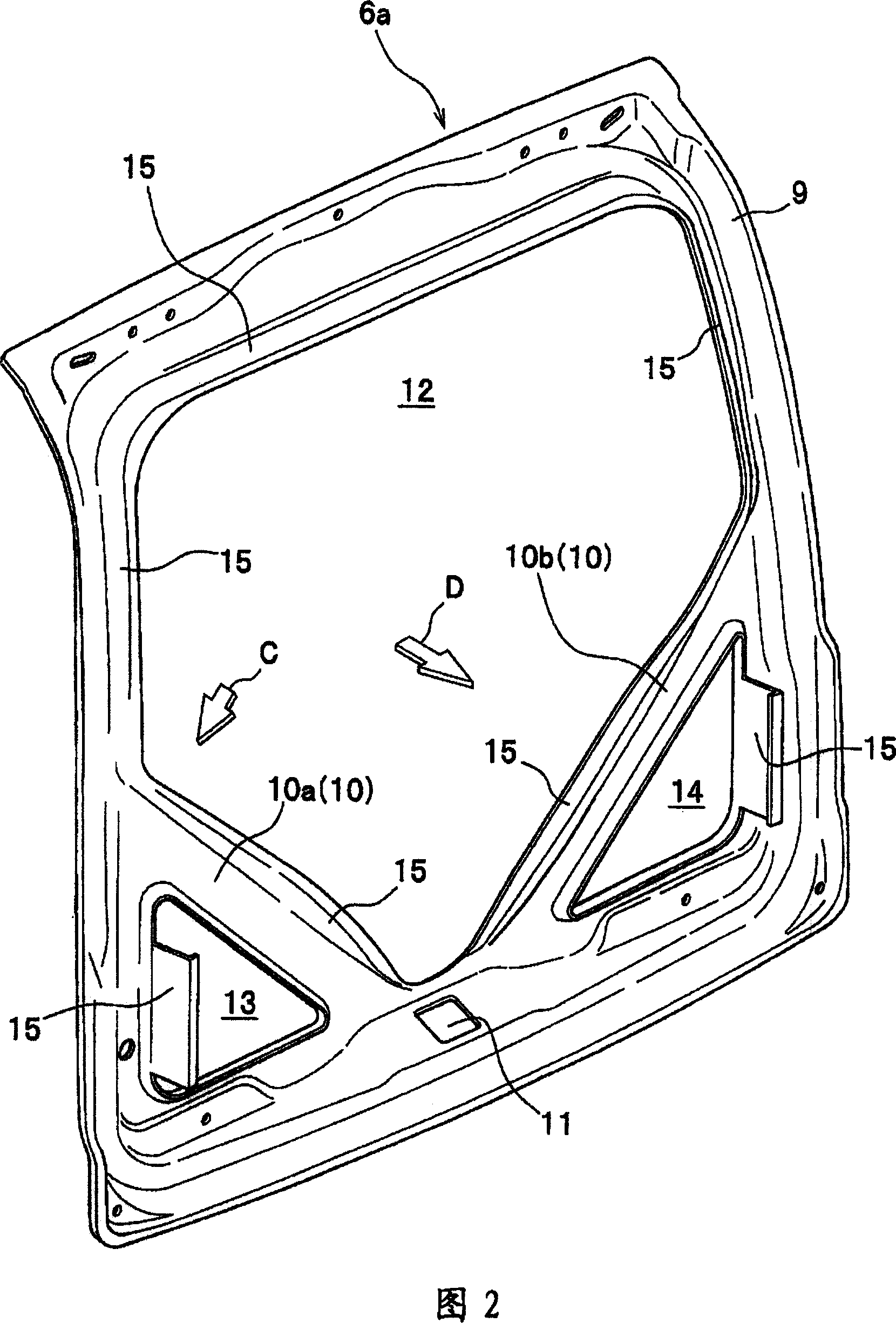

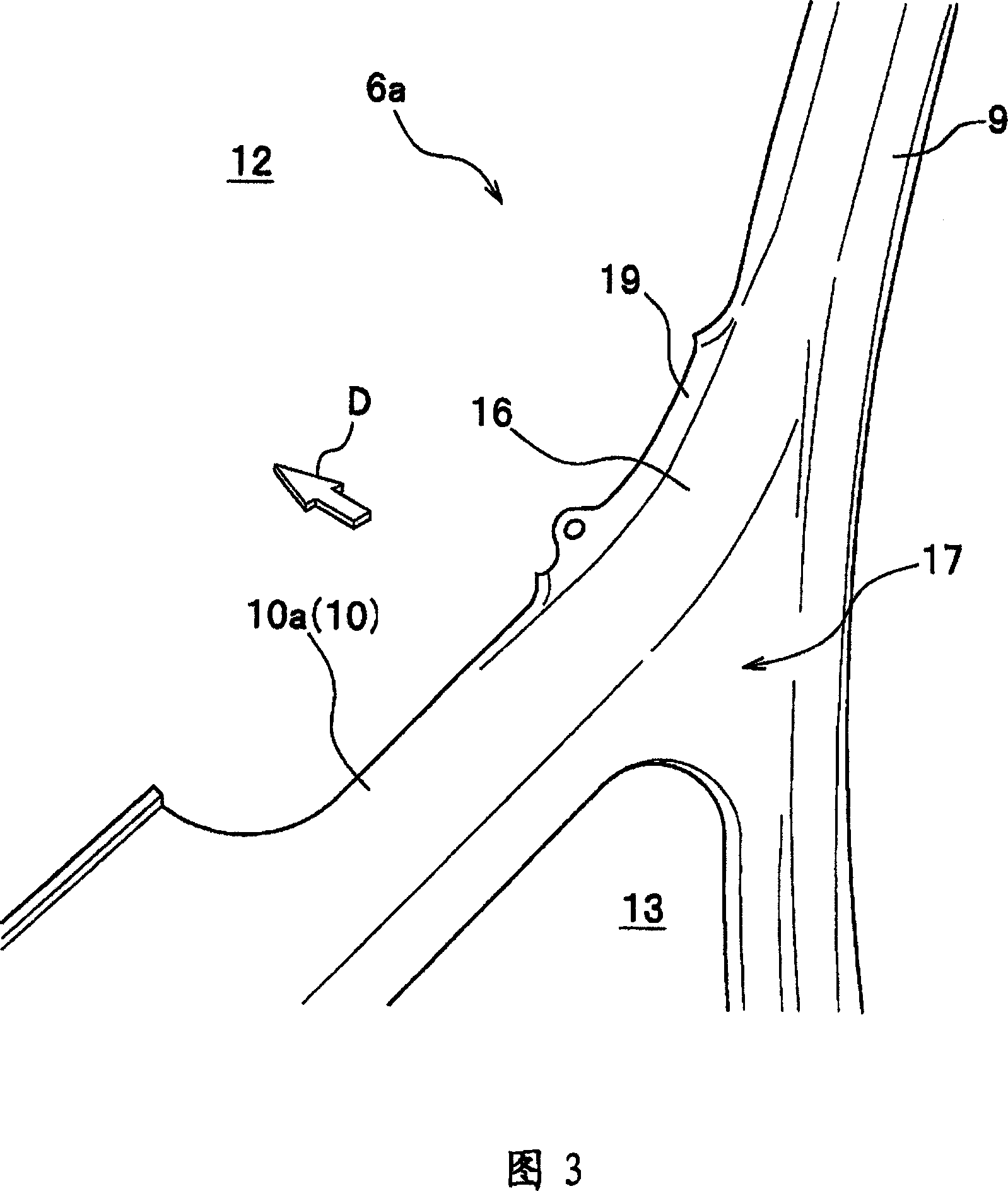

[0097] Next, a vehicle rear door structure according to a first embodiment of the present invention will be described in detail with reference to appropriate drawings. Of the drawings referred to, FIG. 1 is a partial perspective view of a vehicle to which a rear door structure according to a first embodiment is applied. 2 is a perspective view showing a state of an inner panel constituting the rear door structure of the first embodiment, viewed from the outside of the vehicle. 3 is a partial perspective view showing a state from a side portion of an inner panel frame portion to a reinforcement portion as viewed from the inside of the vehicle, and is a view showing a portion indicated by an arrow C in FIG. 2 .

[0098] As shown in FIG. 1, the rear door structure 1a is applied to the rear door 2 which opens and closes the tailgate opening part 3 of the vehicle V. As shown in FIG. Incidentally, the rear door 2 has a lift-up structure, that is, its upper edge and the upper edge o...

no. 2 Embodiment approach

[0115] Next, a vehicle rear door structure according to a second embodiment of the present invention will be described in detail with reference to appropriate drawings. Of the drawings referred to, FIG. 4 is a perspective view showing a state of an inner panel constituting the rear door structure of the second embodiment viewed from the outside of the vehicle. Fig. 5 is an X-X sectional view of Fig. 4 . Fig. 6 is a side view of an inner panel in the second embodiment. Moreover, FIG. 6 shows the state where the hinge is mounted on the inner panel, and the vehicle body to which the inner panel is mounted is shown by a phantom line. In addition, since the rear door structure of this embodiment is configured in the same manner as that of the first embodiment except that the inner panel is different from the rear door structure of the first embodiment, in the following description, the inner panel will be mainly described. , and the same reference numerals are assigned to the sam...

no. 3 Embodiment approach

[0126] In addition, in the above-mentioned second embodiment, the beam 18 is attached as a member separate from the inner panel 6a, but the present invention is not limited thereto. Here, FIG. 7 is a perspective view showing a state of an inner panel constituting a rear door structure according to another embodiment, viewed from the outside of the vehicle.

[0127] As shown in FIG. 7 , the inner panel 6 b constituting the rear door structure 1 c is formed integrally with the inner panel 6 b by press molding, and the beam 18 extending across the connecting portions 17 , 17 is formed integrally.

[0128] In the above-mentioned rear door structure 1c, since the beam 18 is integrally formed with the frame portion 9 and the reinforcement portion 10 (10a, 10b), rigidity is improved, and the rear door structure 1c (inner panel 6b) The manufacturing process is simplified.

[0129] In addition, in the above-mentioned embodiment, although the reinforcing parts 10a, 10b extend in a subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com