Plasma processing apparatus

A technology of plasma and treatment device, applied in the field of plasma treatment device, can solve the problem of ungrounded electrodes, etc., and achieve the effect of excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] An example of the plasma processing apparatus of the present invention will be described in detail below with reference to the drawings.

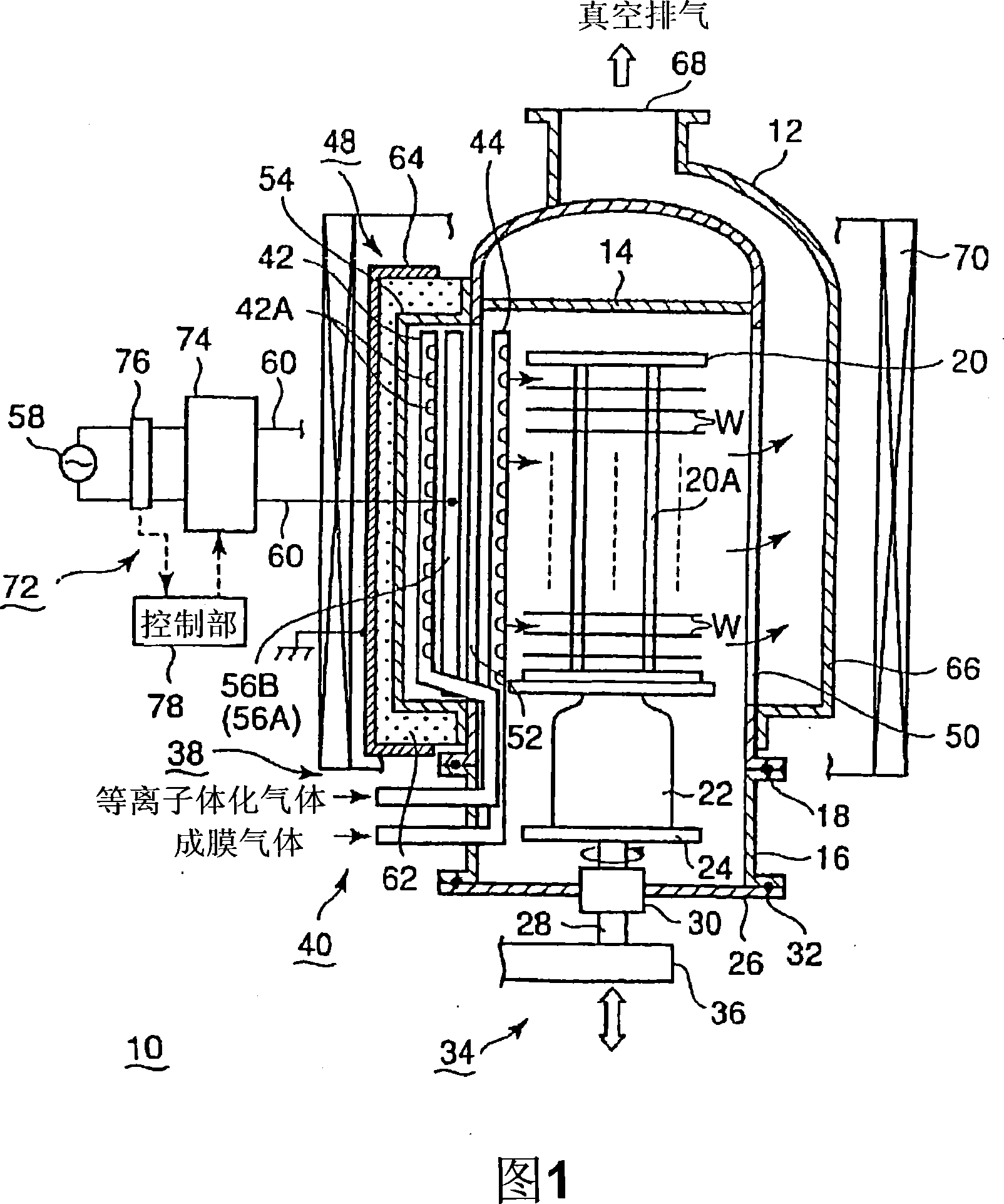

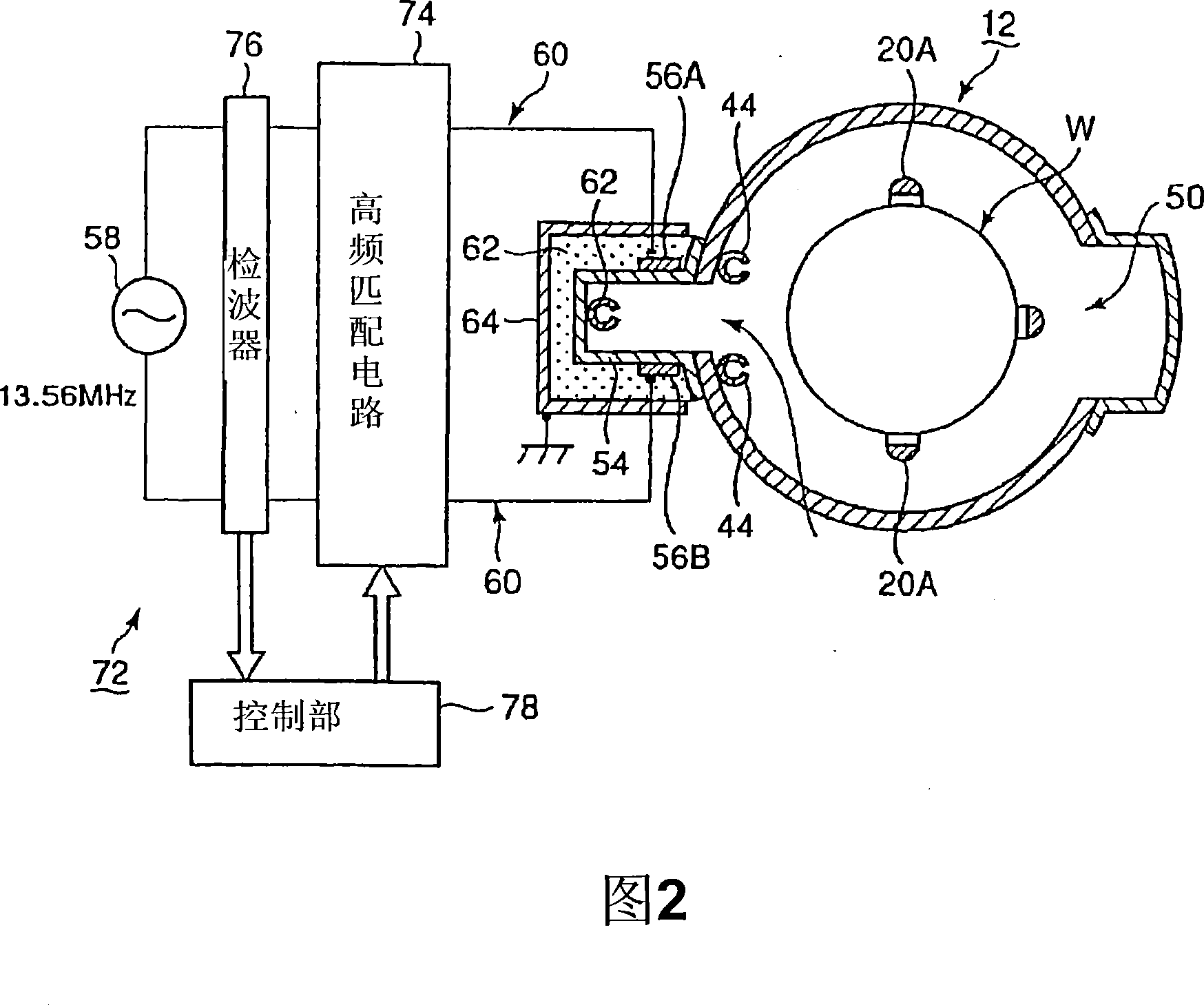

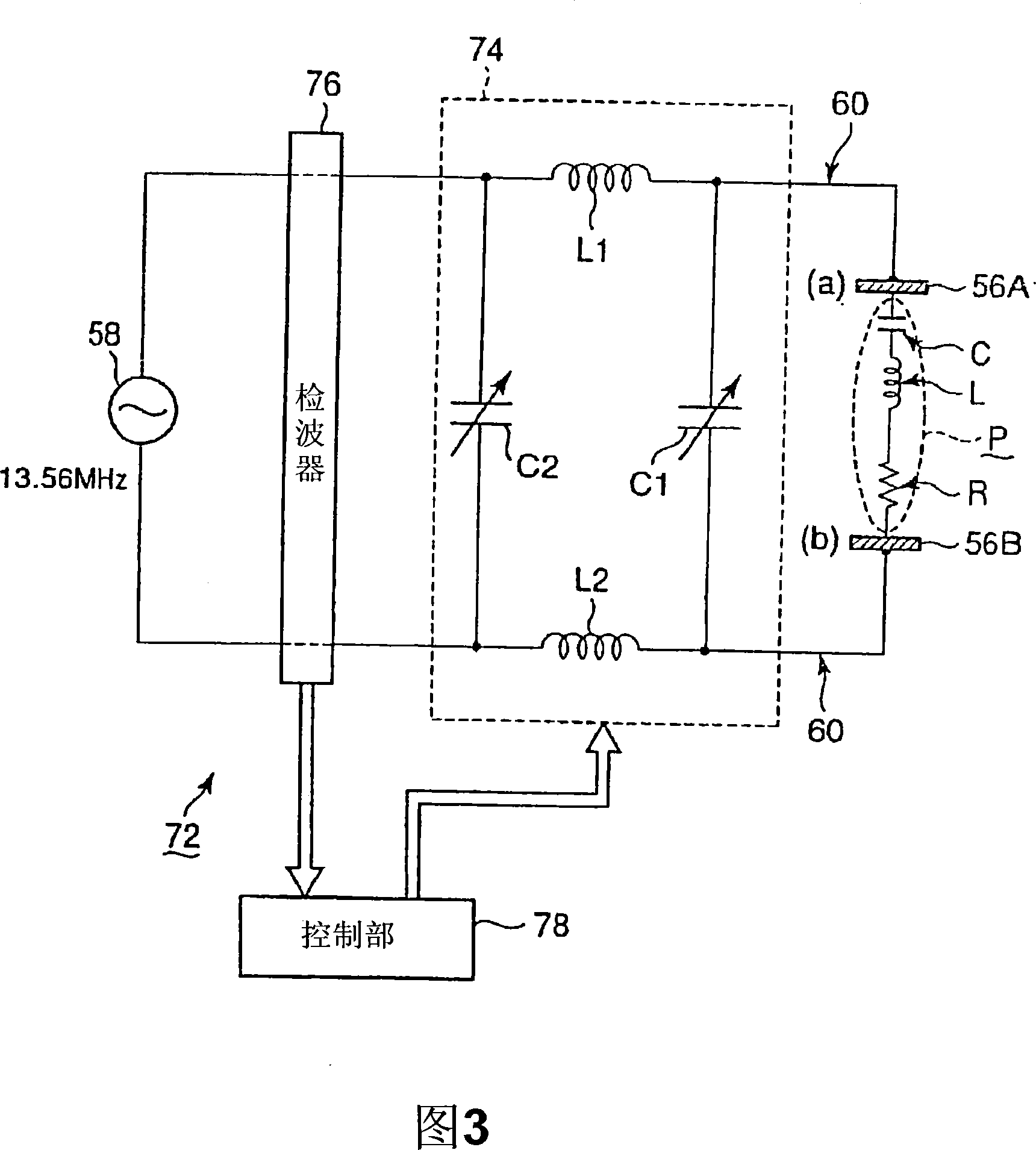

[0045] Fig. 1 is a longitudinal sectional structural diagram showing an example of a plasma processing apparatus of the present invention, Fig. 2 is a cross-sectional structural diagram showing a plasma processing apparatus (heating unit omitted), and Fig. 3 is a diagram showing a high-frequency power supply connected to The equivalent circuit diagram of the frequency circuit. In addition, here, a silicon nitride film (SiN) is formed by plasma CVD using ammonia gas as a plasma gas and hexachlorodisilane (hereinafter also referred to as "HCD") gas as a film-forming gas. Example to illustrate.

[0046] As shown in the figure, this plasma processing apparatus 10 has a topped cylindrical processing container 12 with an open lower end. The processing container 12 is entirely formed of, for example, quartz, and a top plate 14 made of quart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com