Aerosol discharge system

An aerosol and electrode technology, which is used in electrostatic and electrical components to achieve the effect of solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

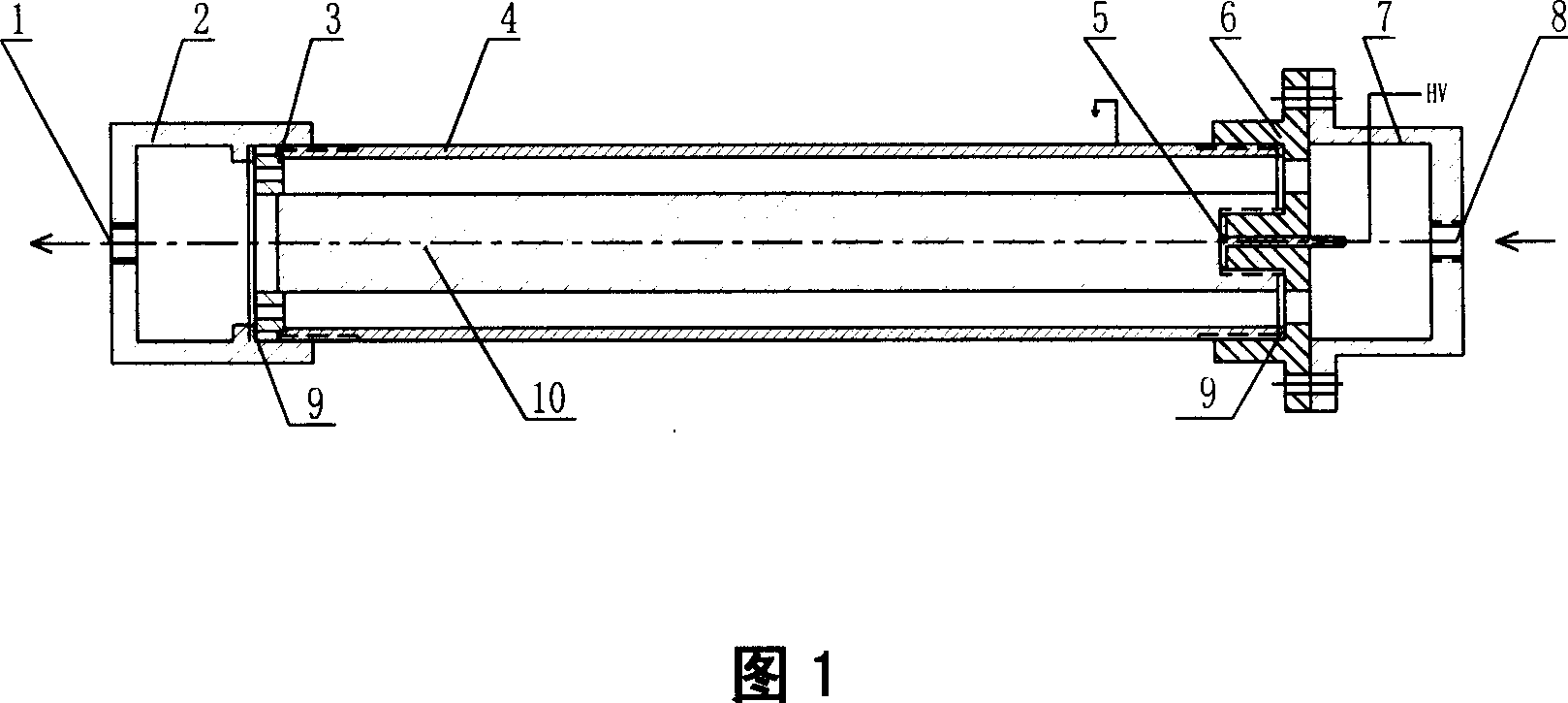

[0013] The principle, structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] Fig. 1 is a schematic structural view of an embodiment of an aerosol power elimination device provided by the present invention. The device comprises an inner shaft electrode 10, an outer cylinder electrode 4 arranged concentrically with the inner shaft electrode, a front support 6 and a rear support 3 for supporting the inner shaft electrode, a front end cover 7 and a rear end cover 2 arranged at both ends of the electrode; The front and rear brackets are respectively provided with through holes, and the front and rear end covers are respectively provided with an aerosol air inlet 8 and an air outlet 1, and a conductive probe 5 is embedded in the inlet end of the inner axis electrode. Connected to the current power supply, and the outer cylinder electrode is grounded. The rear end cover 2 is connected to the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com