Secondary battery employing battery case of high strength

A secondary battery, battery case technology, applied in secondary batteries, battery pack components, battery boxes/jackets, etc., can solve problems such as explosion, intrusion, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1

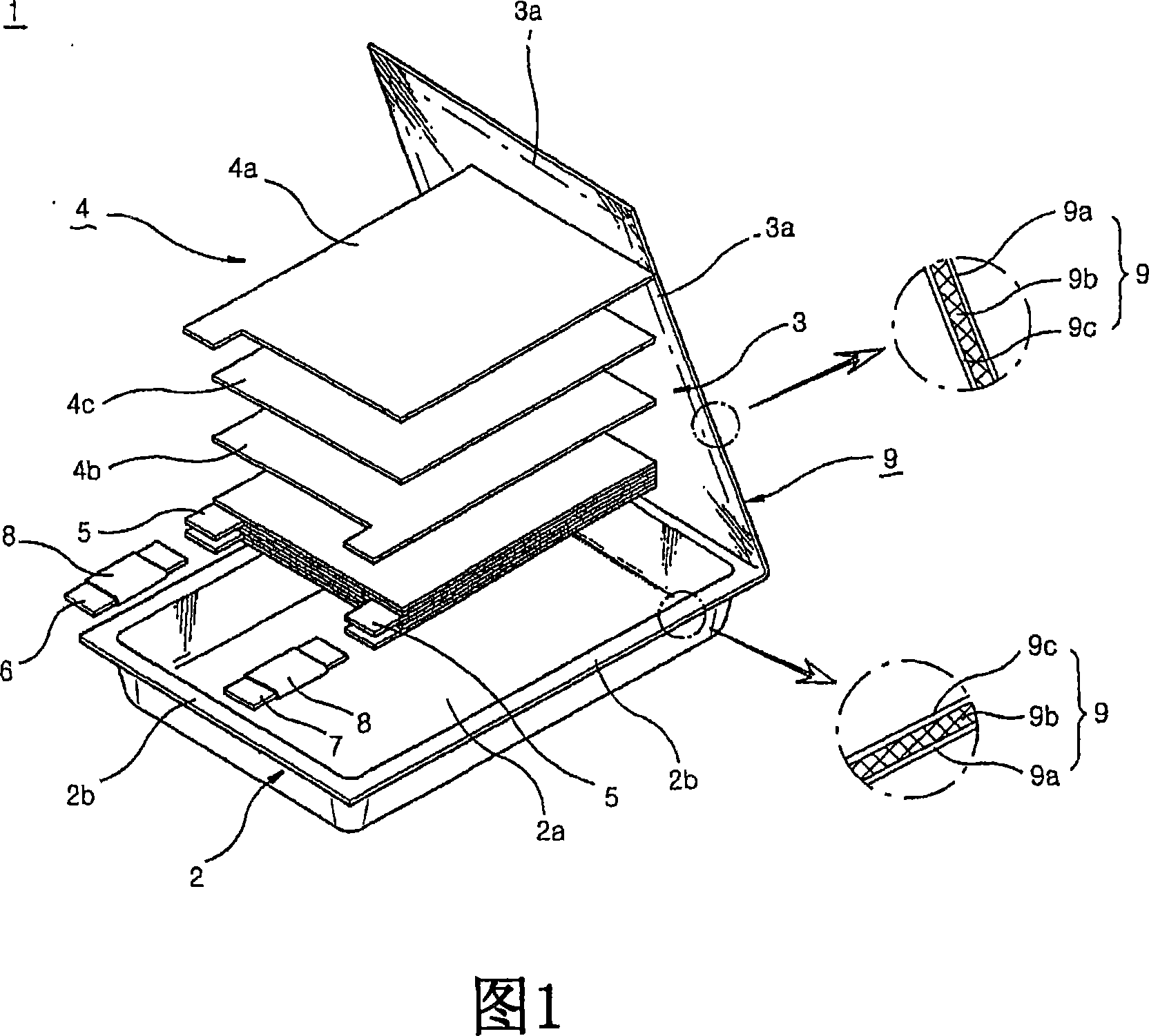

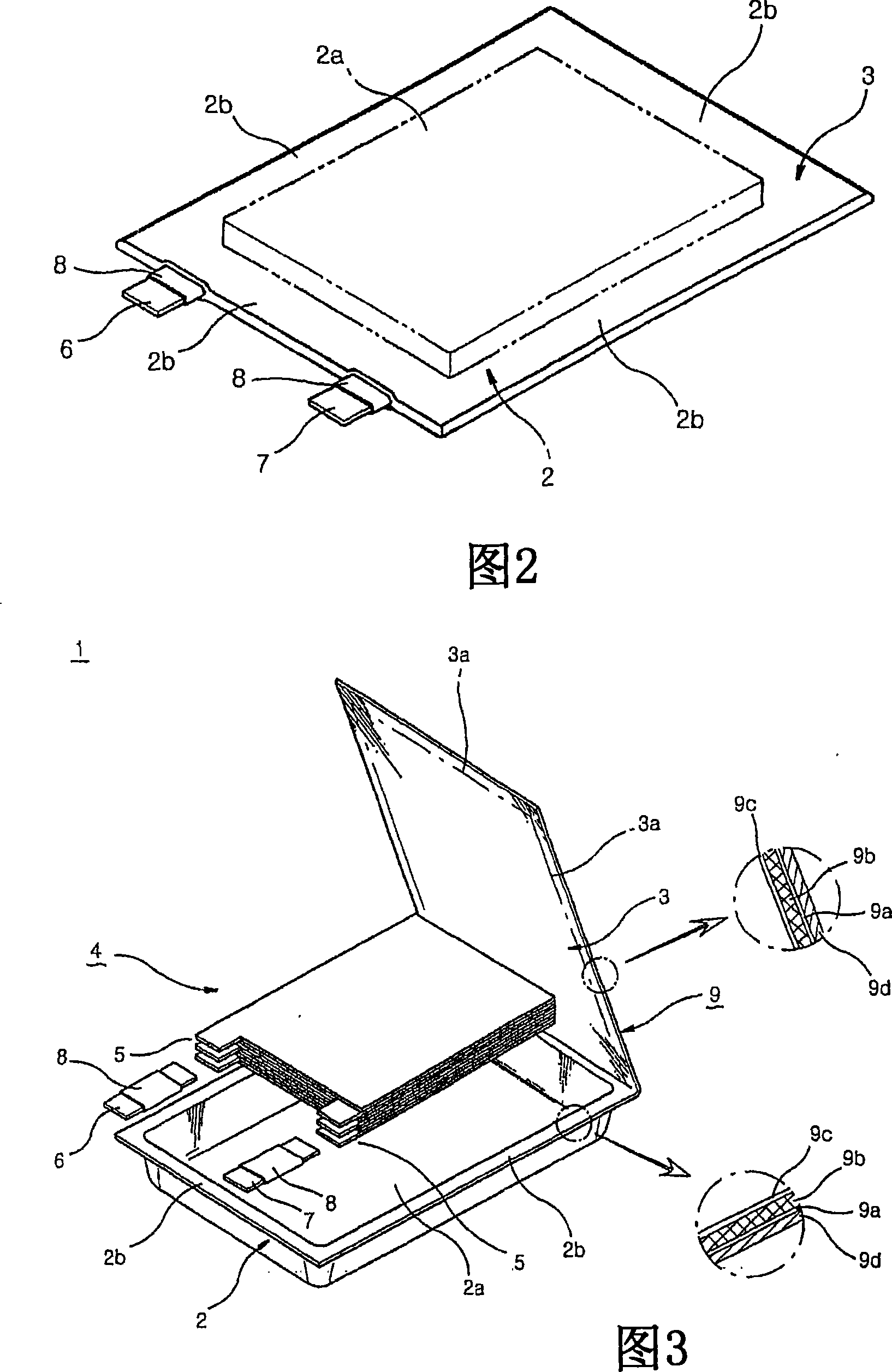

[0037] Laminates were prepared according to the synthesis formula in Table 2 below. Using the laminated sheet thus produced, a pouch-type battery case having a structure as shown in FIG. 3 was prepared by dry lamination.

[0038]

[0039] Structure of the laminate

[0040] Note: The right suffix for PET, ONy, PEN, Al and CPP indicates the thickness.

[0041] A laminated type electrode assembly, as shown in FIG. 3, is installed in each battery case, and the resulting structure is filled with electrolyte. Then, the case and the cover were heat-sealed therebetween, thereby producing a pouch-type battery.

[0042] The puncture resistance of the thus-prepared batteries was tested under the conditions of FTMS 101C using a battery puncture tester (UTM tester). The results obtained are given in Table 3 below. The puncture resistance strength of the above-described device is represented by the force measured when the needle-like member penetrates the battery case by pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com