Root crop combine harvester

A technology for combine harvesters and rhizomes, which is applied to excavator harvesters, harvesters, and de-roofing machines, etc., can solve the problems of restricting the level of mechanized harvesting, low level of mechanization, and small annual workload of machines and tools, and achieves good application promotion. Prospects, reduce the cost of use, and increase the effect of the annual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

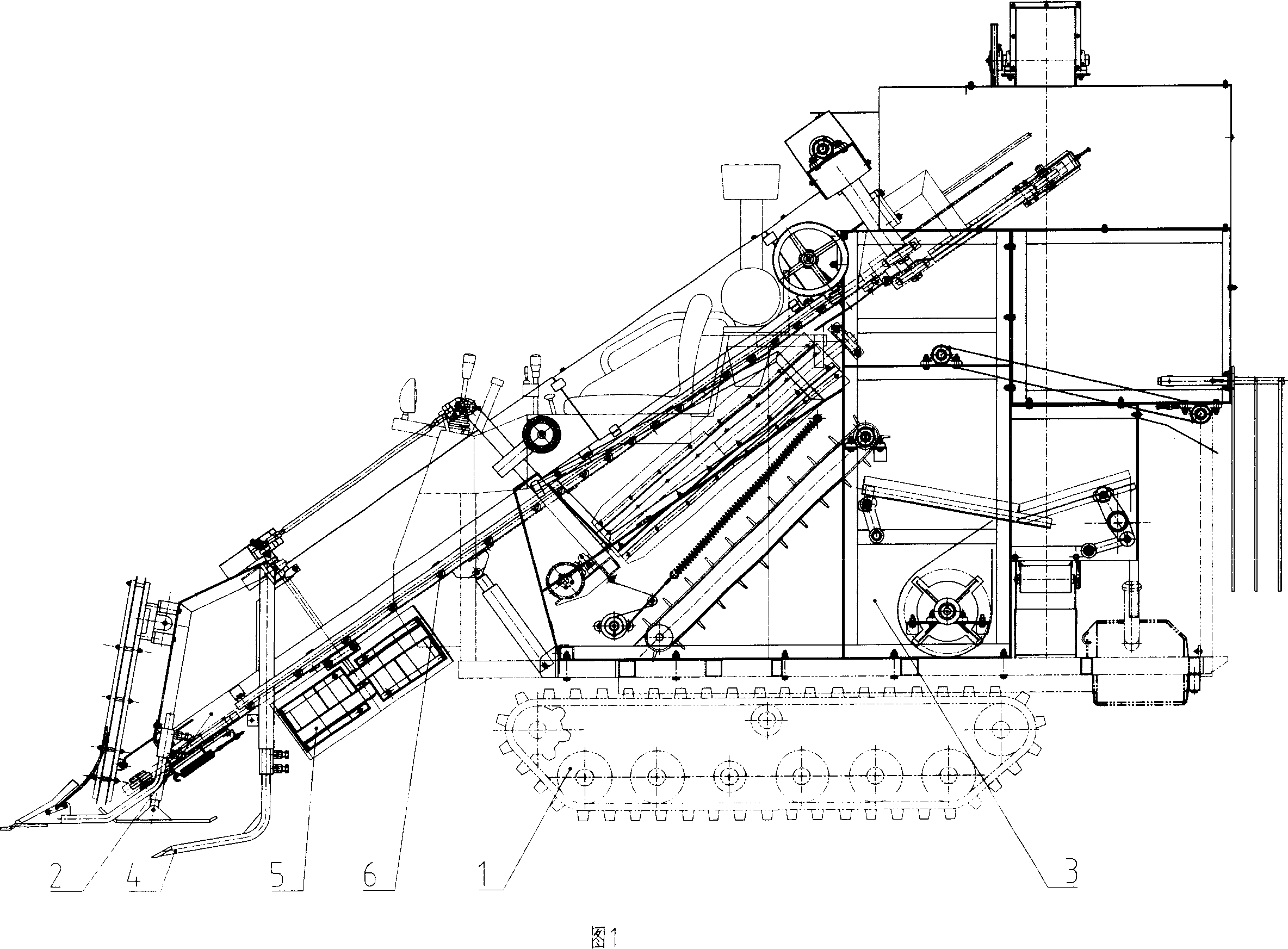

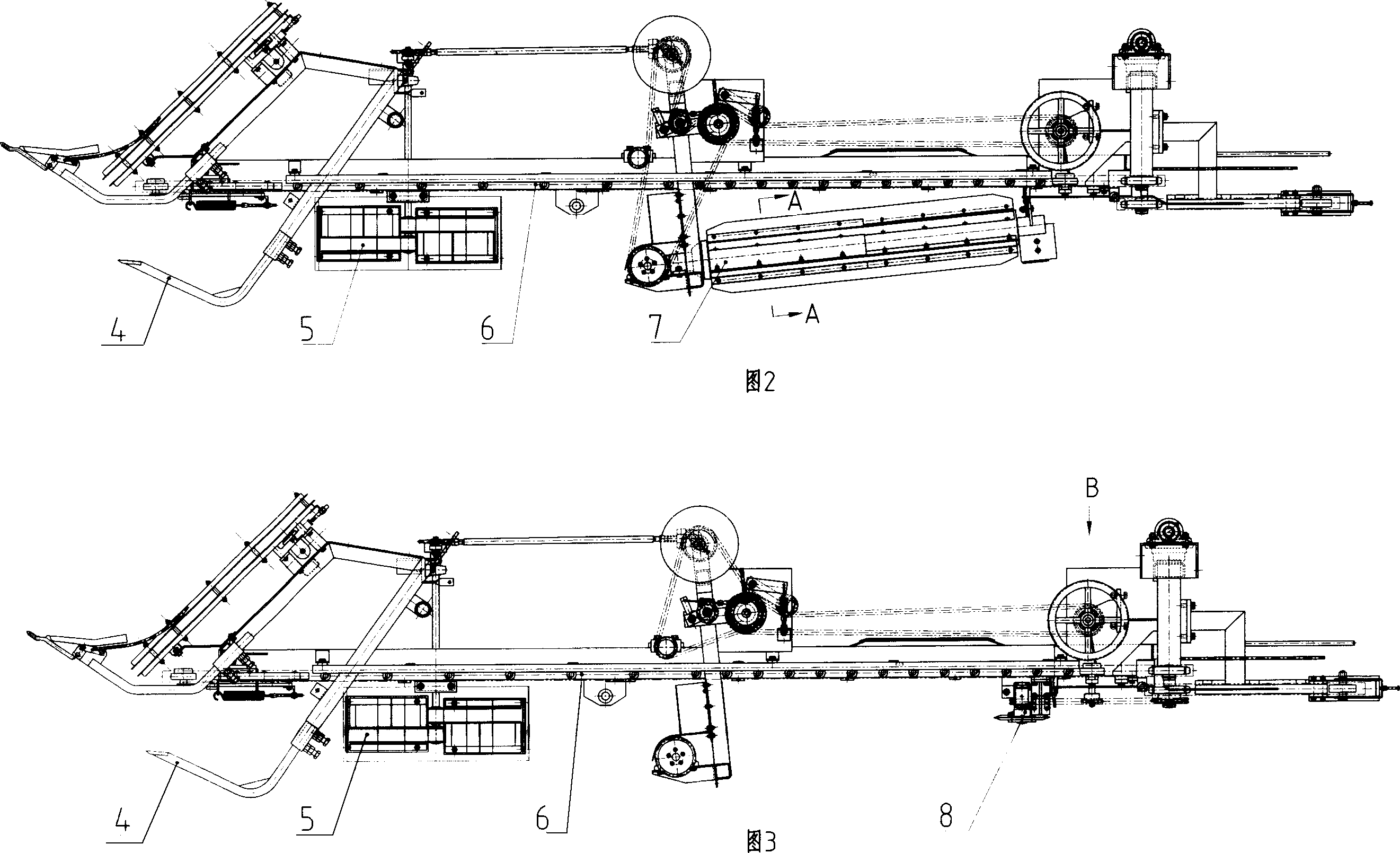

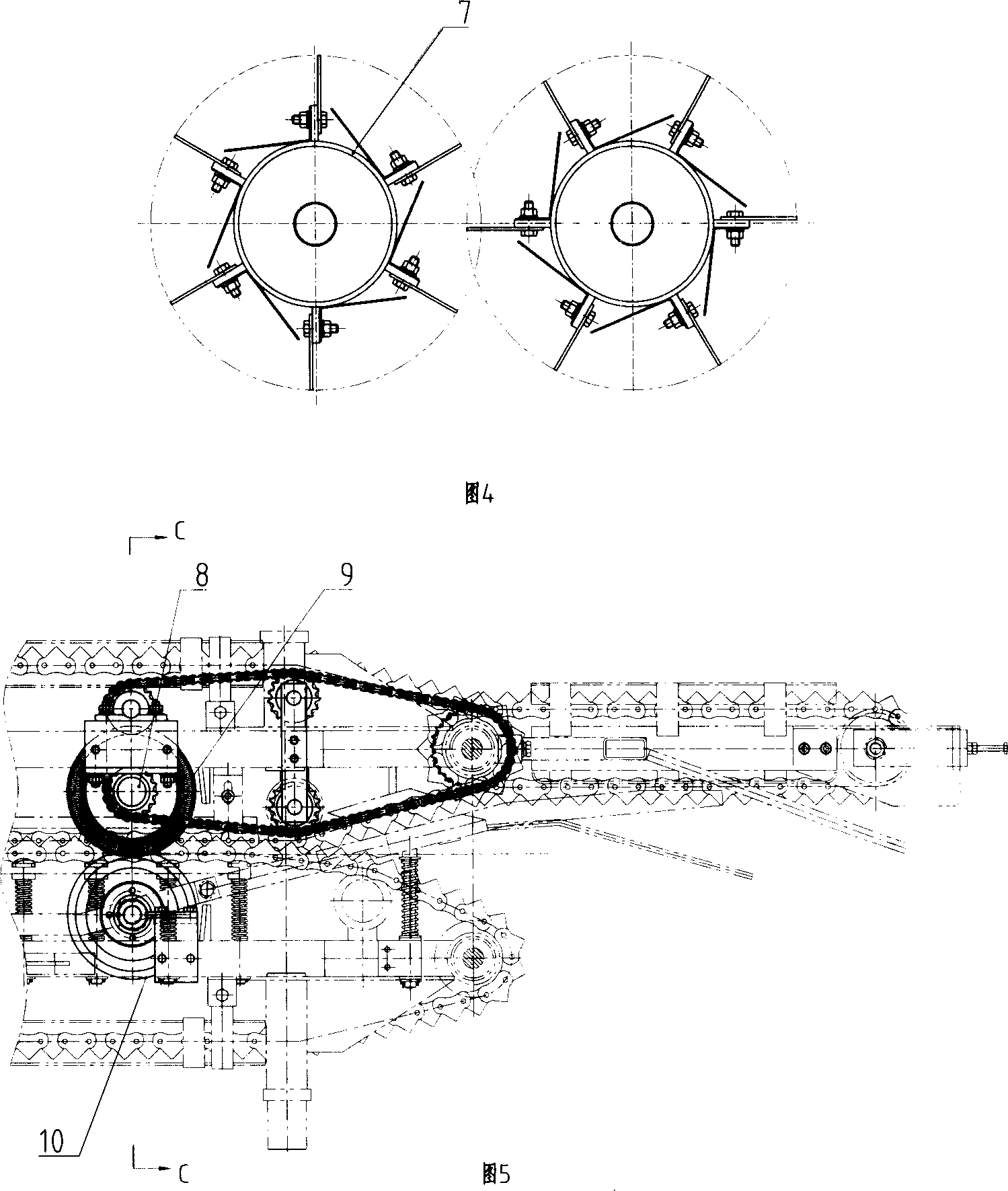

[0017] As shown in Figures 1 to 3, the rhizome crop combine harvester of this embodiment includes a power walking chassis 1, a main frame 3, a harvesting platform 2, a digging shovel 4, a soil removal mechanism 5, a blade drum type separation mechanism 7, a disc cutter Knife type separating mechanism 8 and clamping conveying mechanism 6. The main frame 3 is installed on the chassis 1, the harvesting platform 2 is hinged with the main frame, the digging shovel 4 is installed on the front end of the harvesting platform 2, the soil removal mechanism 5 and the separation mechanism (blade drum type separation mechanism 7 or disc cutter type separation mechanism 8) It is arranged behind the digging shovel 4 in sequence, and the clamping and conveying mechanism 6 is installed above the digging shovel 4, the soil removal mechanism 5 and the separation mechanism.

[0018] In order to realize one machine with multiple functions, the rhizome crop combine harvester of the present embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com